Preprocessing method and preprocessing device for steel plate trimming

A cutting device and edge trimming technology, which is applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problem of metal loss, the difficulty of accurately controlling the shear width value, and affecting the steel yield of the production line, etc. problem, achieve the effect of reducing shear load, improving effect and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

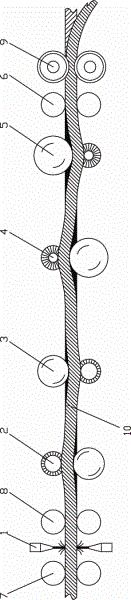

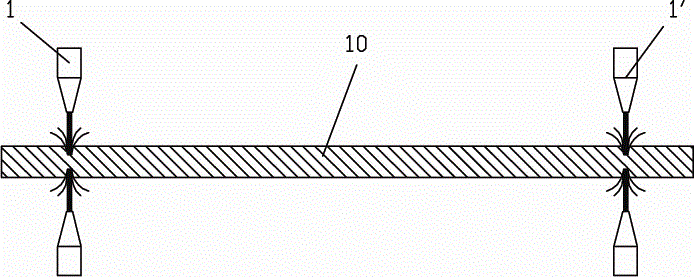

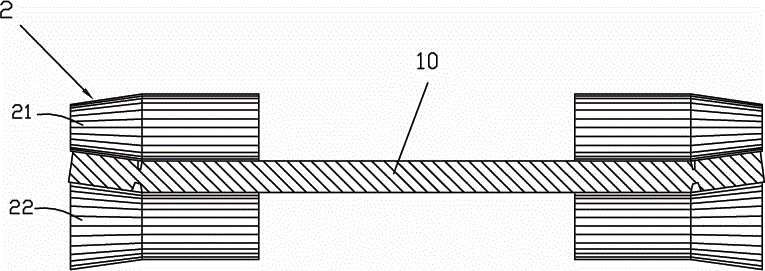

[0027] see figure 1 , a pretreatment device for trimming strips of the present invention, which includes at least two groups of cutting devices 1, 1 ', which are respectively arranged on both sides of the strip 10, corresponding to both sides of the strip; several bending roller groups 2 . The group (take the bending roller group 2 as an example) is composed of two upper and lower rollers 21, 22, each arranged on the upper and lower sides of the strip 10; the upper and lower rollers 21, 22 have different inclinations of tapered sections or sector sections , that is, the upper roll 21 of a roll group is a tapered section, and the lower roll 22 of the roll set is a fan-shaped section, which is matched in pairs; two pairs of flat rolls 6, 6' are respectively arranged on both sides of the strip steel 10, along the The running direction of the steel strip 10 is behind the bending roller group 5 .

[0028] Further, along the running direction of the strip, the farther the bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com