Internal screw thread processing method

An internal thread processing and internal thread technology, applied in thread cutting tools, metal processing equipment, manufacturing tools, etc., can solve the problems of letting the knife and the knife not be too deep, and the product quality cannot be guaranteed, and achieve the effect of increasing the support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

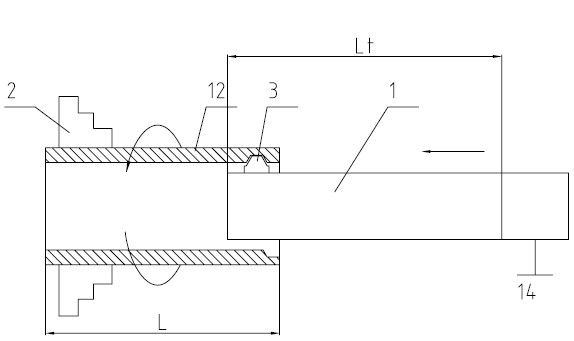

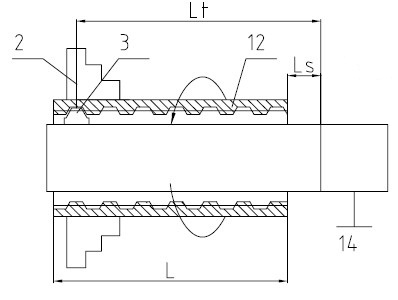

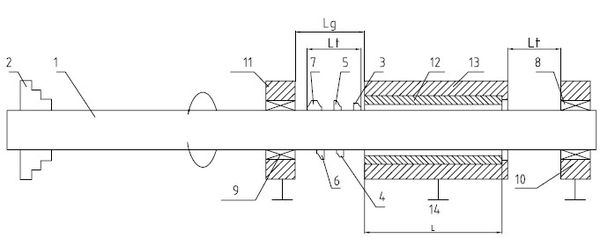

[0066] Below in conjunction with accompanying drawing this patent is described, in figure 1 and figure 2 Among them, f1= , where f1 is the deflection, also known as the amount of deformation, P is the cutting force, L is the length of the workpiece, E is the modulus of elasticity, and I is the moment of inertia. At this time, if the gap length Ls of the tool bar is ignored, the cantilever length Lt of the tool bar Approximately equal to the length L of the workpiece, the deflection of the tool holder at the blade is f1. However, when processing slender internal threads (for example, the diameter of the thread is less than 20mm, or the ratio of the length to the diameter of the thread is greater than 10 at the same time), because the tool shaft is thin and only the force is applied to the front end blade, it becomes a cantilever beam. The resulting deflection is too large, it is easy to produce a knife, and the knife cannot be too deep, which not only reduces the production...

Embodiment 2

[0072] If the length-to-diameter ratio of the internal thread is not too large, the openable bearing on the left ( Figure 8 ), at this time, the length Lw between the two supports of the tool bar is approximately equal to twice the length L of the workpiece, and the deflection of the tool bar at the blade is f3, f3= = = , f3 / f1=1 / 2, that is to say, the deflection of the tool holder is only 1 / 2 of the traditional processing method.

Embodiment 3

[0074] There are two methods of thread tooth shape.

[0075] The first type: several pieces of cutting section can be used to be the same or similar to the profile of the thread to be processed but the height ( Figure 9 Middle Ht) Different blades f, blade g and blade h are cut in sequence, and finally the entire tooth profile is processed. This method is generally applicable to threads with small tooth profiles such as triangular threads and rectangular threads.

[0076] The second type: use several blades that are different in shape from the tooth shape but can cover the entire tooth shape after being superimposed ( Figure 10 Middle blade a, blade b, blade c, blade d) are cut in sequence, and finally the entire tooth shape is processed. This method is generally suitable for trapezoidal threads or other threads with complex tooth shapes and large tooth profile sections.

[0077] Regardless of the first or second division method, if in order to improve the accuracy of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com