Arc welding robot oscillating electric arc tracking system and method based on DSP (Digital Signal Processor)

A robot and arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high cost, unfavorable system integration and wide application, achieve good welding quality, and realize welding seam tracking and swing adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention will be further described in detail in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

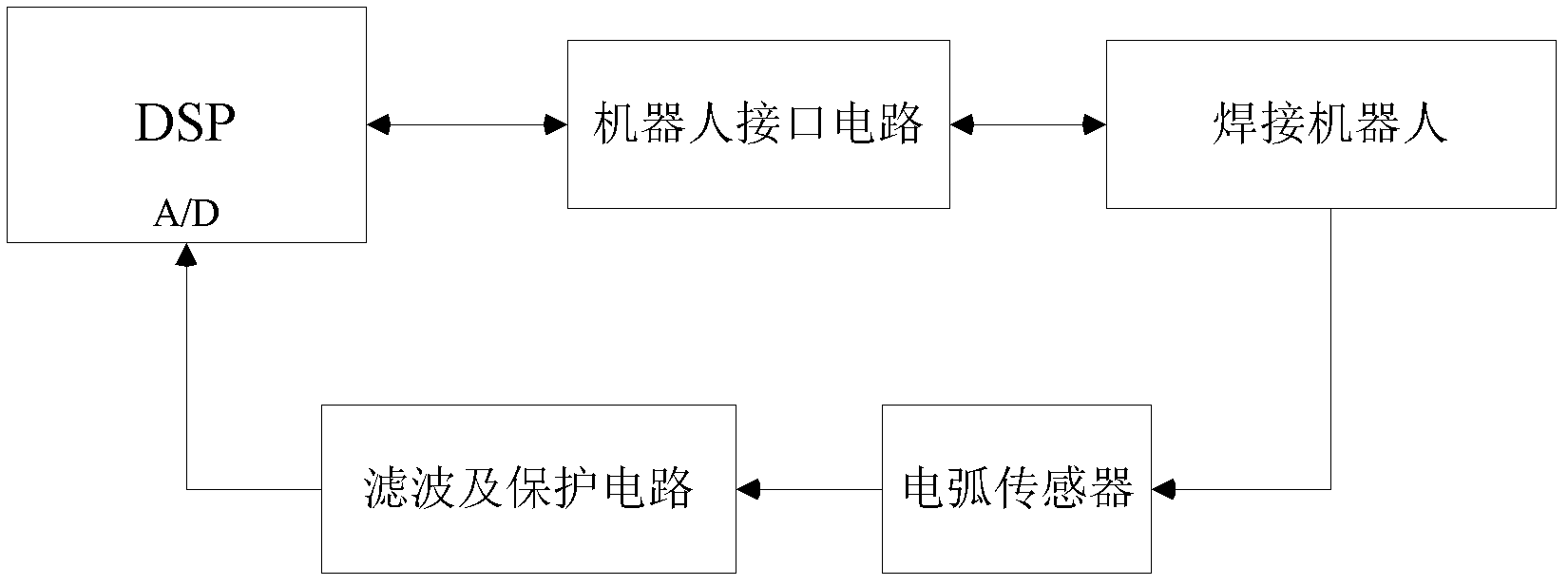

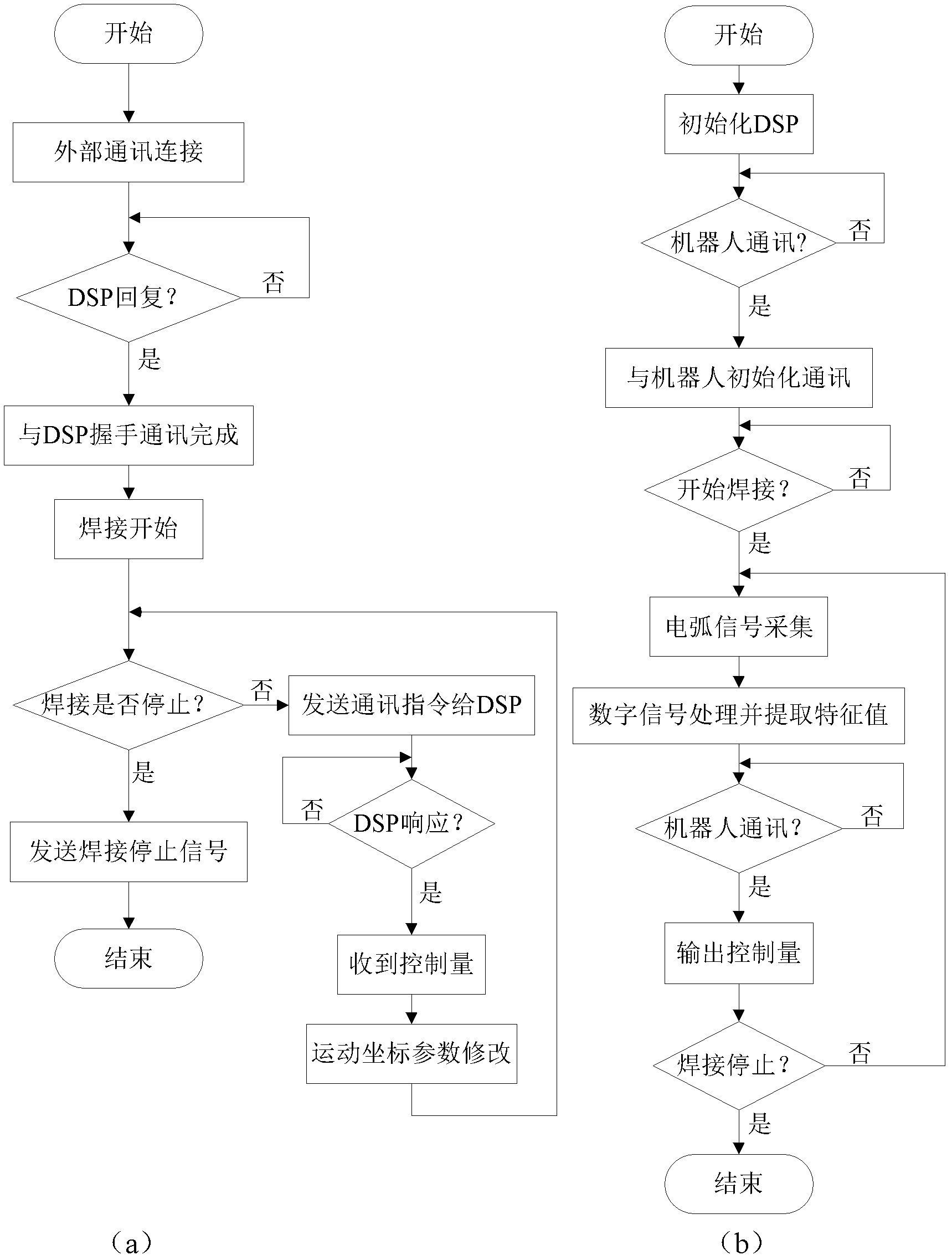

[0021] Such as figure 1 As shown, the DSP-based arc welding robot swing arc tracking method and control system of this embodiment include: welding robot, arc sensor, filter and protection circuit, DSP, robot interface circuit, wherein:

[0022] Welding robot, with GMAW welding torch installed at the end joint, swings left and right relative to the welding direction to weld the workpiece; sends signals to DSP to start welding, stop welding and swing position from side to side; accepts the offset signal sent by DSP, and changes the welding path to achieve Weld deviation corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com