Powder feeding device

A feeding device and powder technology, applied in packaging, transportation and packaging, railway car body parts, etc., can solve problems such as potential safety hazards, inability to realize vibration screening, lack of heat preservation treatment, etc., and achieve easy transfer, remote control and landing The effect of material speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

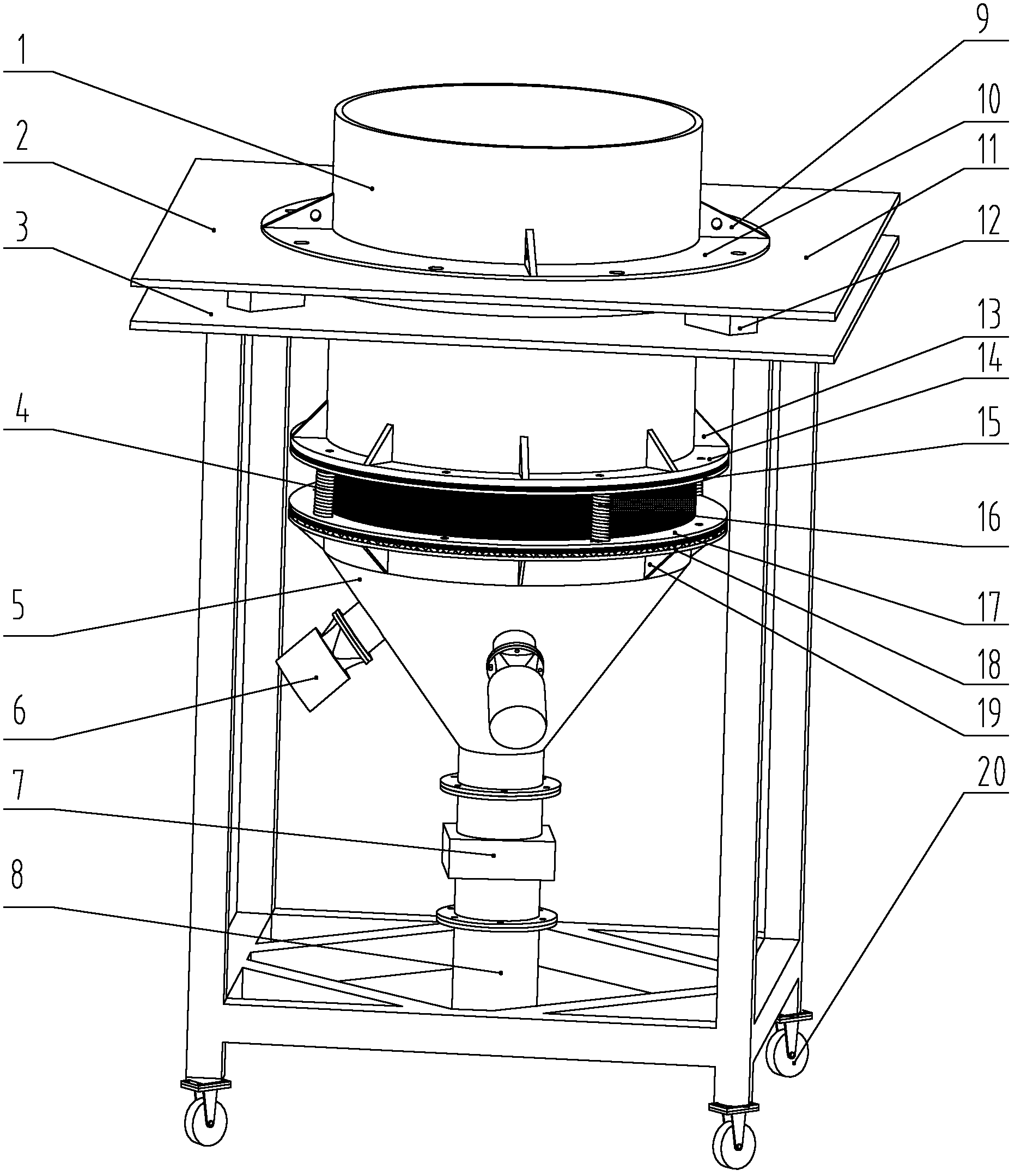

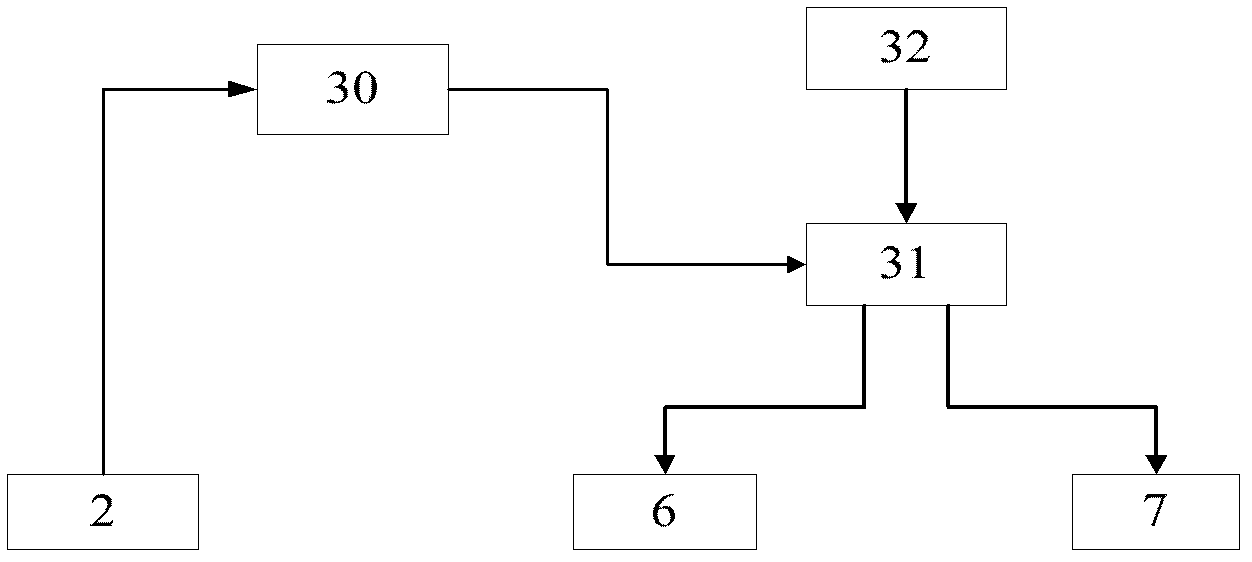

[0028] The first embodiment of the present invention is figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a thermal insulation barrel 1, a weighing device 2, a support 3, a hopper 5, a controller 30 and an electric proportional regulating valve 31, the support 3 is a frame structure, and the weighing device 2 is installed on the support 3 The end face, the insulation material cylinder 1 passes through the upper end surface of the bracket 3, the upper part of the insulation material cylinder 1 is rigidly connected with the weighing device 2, and the lower end surface of the insulation material cylinder 1 is flexibly connected with the hopper 5;

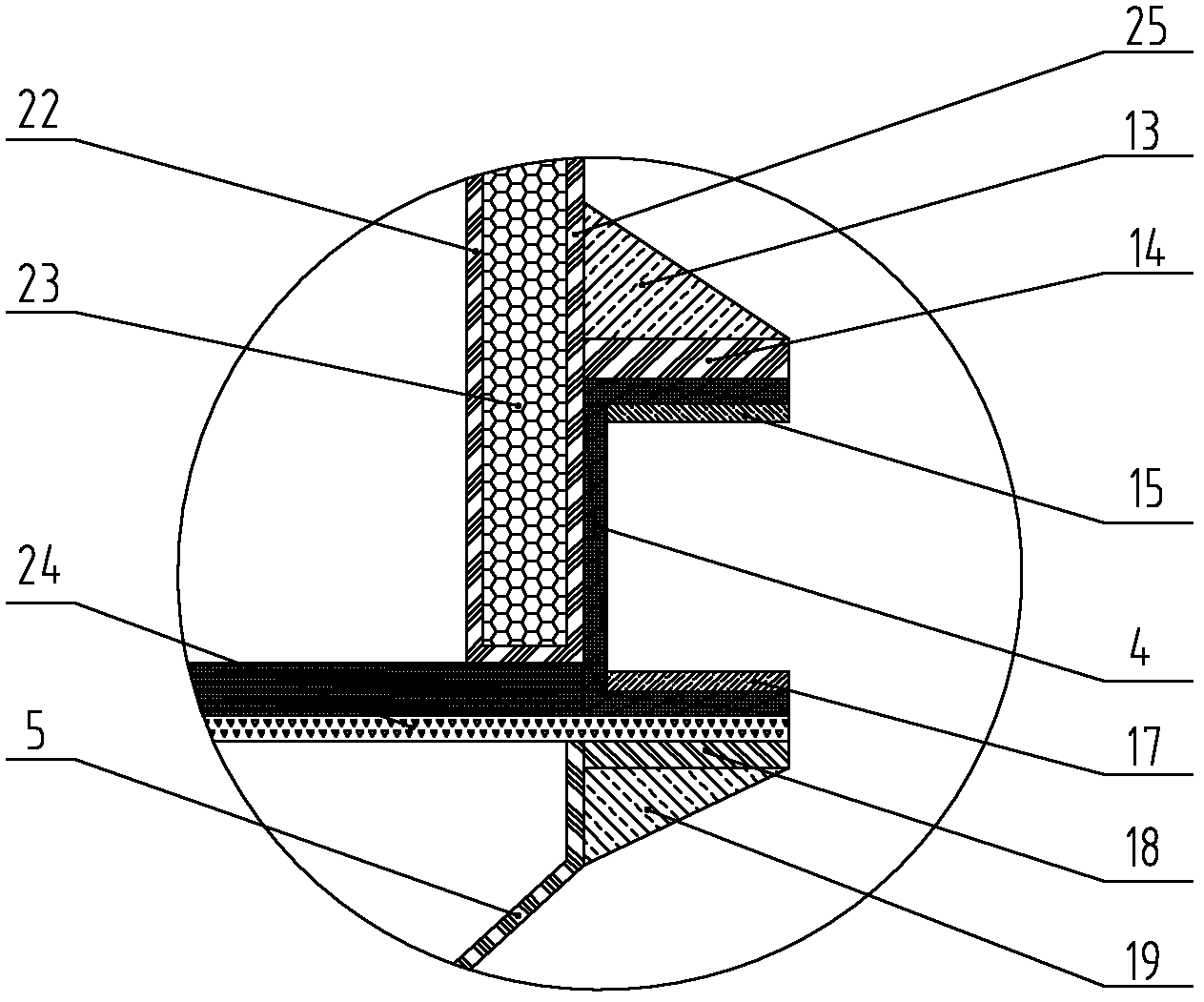

[0029] The heat preservation barrel 1 has a sandwich structure, and there is a heat preservation filler 23 between the inner wall 22 and the outer wall 25; seal fit;

[0030] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com