Preparation method for chalcogenide semiconductor/carboxylation PPV (polyphenylene vinylene) electroluminescence composite material

A composite material and semiconductor technology, which is applied in the field of preparation of chalcogen semiconductor and carboxylated PPV derivative composite materials, can solve the problems of difficult dispersion of inorganic particles, phase separation of organic matter and inorganic particles, etc., so as to improve the photoelectric performance and luminous intensity , High luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

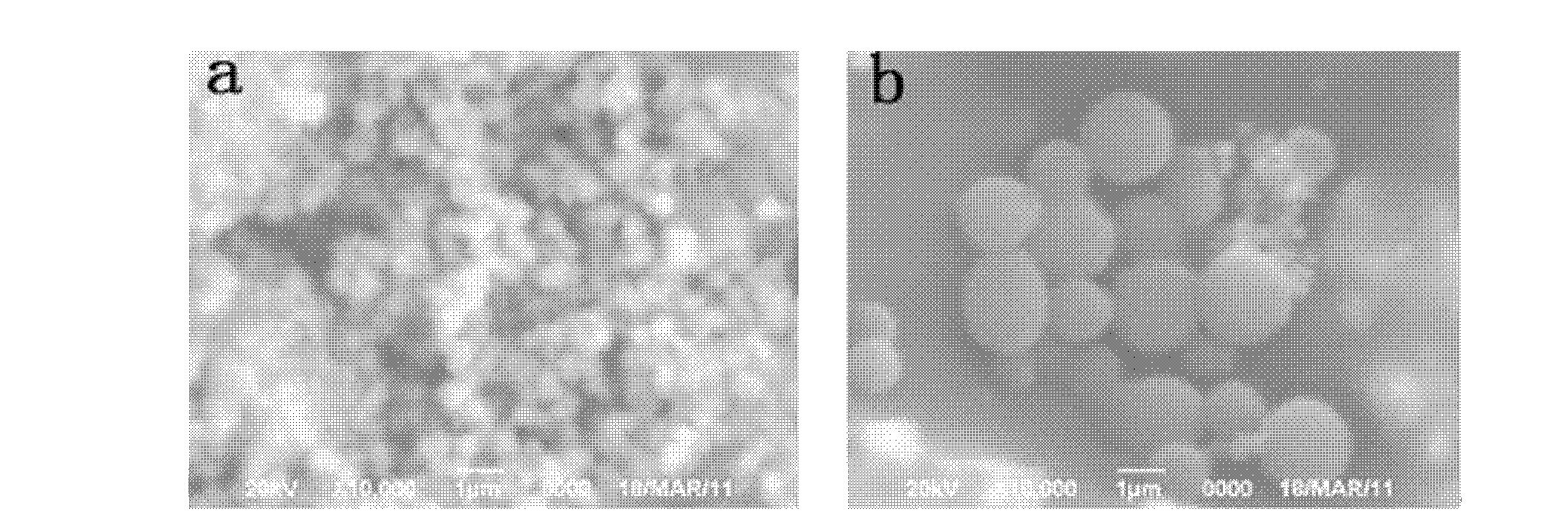

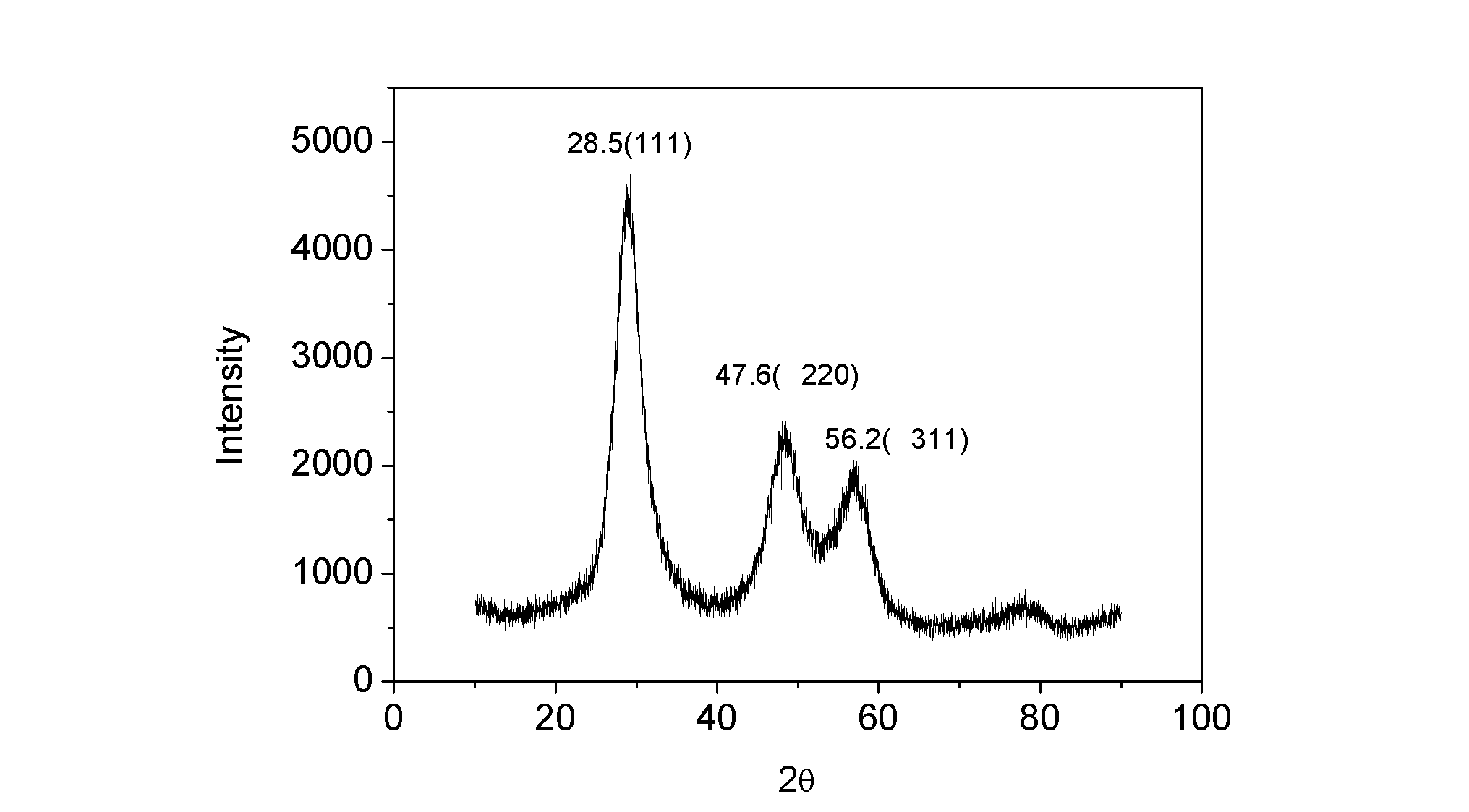

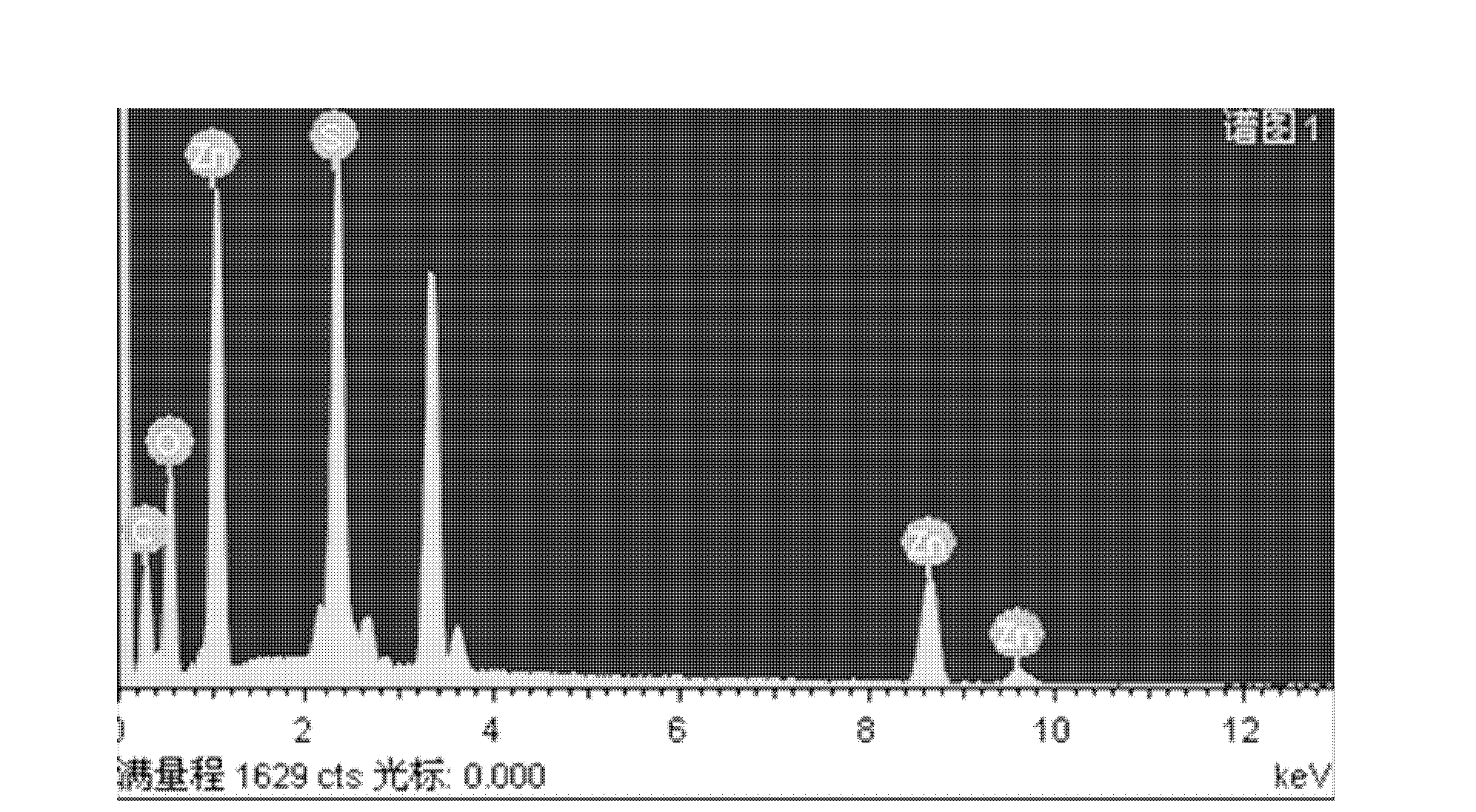

[0035] Embodiment 1: the preparation of ZnS / carboxylated PPV composite material

[0036] 1. Using p-cresol and 6-bromohexanoic acid as raw materials, synthesize carboxylated PPV—poly[2-methoxy-5-(5′- Carboxypentyloxy) p-phenylene vinylene].

[0037] 2. Add methanol and 0.2g carboxylated PPV to the Erlenmeyer flask, stir and dissolve completely, then add 0.32g zinc nitrate dropwise (zinc nitrate is dispersed in 30mL methanol) and react at 85°C for 1 hour to separate the complex and remove the complex The compound was washed with distilled water and dried, then dissolved in methanol and ultrasonically dispersed for 1 h. After the dispersion was uniform, the pH was adjusted to 10 with 1 mol / L NaOH, and 0.04 g of thiourea was added slowly (thiourea was dispersed in 30 mL of methanol). React in the kettle at 80°C for 6 hours, centrifuge to separate the solid matter, and dry in vacuum to obtain the ZnS / carboxylated PPV composite material.

Embodiment 2

[0038] Embodiment 2: Preparation of ZnS / carboxylated PPV composite material

[0039] The preparation method of this embodiment is the same as that of Example 1, and the difference is that Na 2 S is the sulfur source to prepare composite materials.

[0040] By comparison, it can be seen that the light-on voltage of the composite material can be reduced by 0.5-1v relative to pure PPV, and the luminous intensity of the electroluminescent device prepared by using the composite material as the light-emitting layer is higher than that of the electroluminescent device prepared by pure PPV as the light-emitting layer. Increased by 63%, and the start-up voltage is reduced by 1.2V.

Embodiment 3

[0041] Embodiment 3: the preparation of CdS / carboxylated PPV composite material

[0042] 1. Using p-cresol and 6-bromohexanoic acid as raw materials, synthesize carboxylated PPV—poly[2-methoxy-5-(5′- Carboxypentyloxy) p-phenylene vinylene].

[0043] 2. Add methanol and 0.2g carboxylated PPV into the Erlenmeyer flask, stir and dissolve completely, then add 0.32g cadmium chloride dropwise (cadmium chloride is dispersed in 30mL water and add dropwise), react at 85°C for 1 hour, separate the complex, and use Wash with distilled water and dry, dissolve the complex in methanol and ultrasonically disperse for 1 hour, slowly add methanol solution of thiourea after the dispersion is uniform, pour it into a hydrothermal kettle, react at 60°C for 6 hours, centrifuge to separate the solid matter, and dry in vacuum to obtain CdS / Carboxylated PPV composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com