Composition, LED (light-emitting diode) circuit board substrate comprising same and preparation method thereof

A composition and carboxyl technology, applied in chemical instruments and methods, aldehyde/ketone condensation polymer adhesives, printed circuit manufacturing, etc., can solve the problems of poor adhesion, poor processing performance, poor flexibility, etc. The effect of knot force, low equipment cost and low cost requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

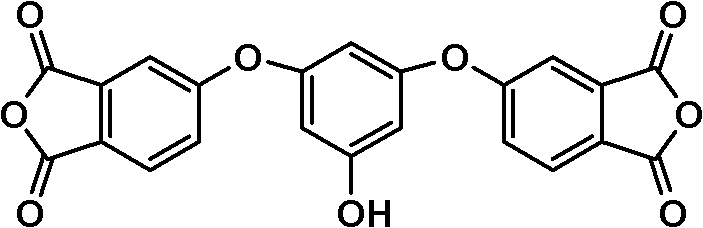

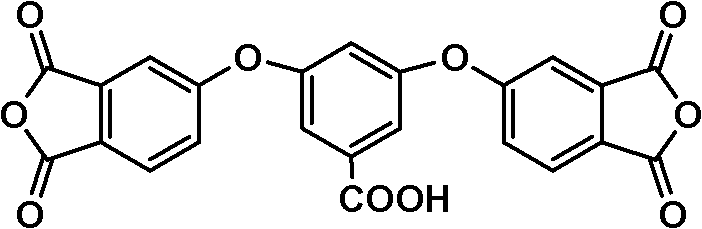

[0070] At room temperature, in a 500ml three-neck flask, add 200g of dimethylformamide, then add 9.8g of m-phenylenediamine and 4.3g of 3,3-diaminodiphenyl ether sulfone, under nitrogen protection, stir at a medium speed to dissolve completely , then gradually add 5.1g bisphenol A type diether tetraacid dianhydride, 33.5g 5-hydroxytriphenyl ether tetraacid dianhydride, add 0.5h, then stir for 4h, then add 0.6g4-hydroxyphthalic anhydride, stir for reaction 2h, forming a viscous polyamic acid resin solution. Mix 2g of acetic anhydride and 2g of triethylamine in 5g of dimethylformamide, and then slowly add it into the polyamic acid resin solution with a constant pressure dropping funnel. After 0.2h, the reaction is stirred for 0.5h, and then the temperature is raised to 120°C, stirred for 2 hours and then cooled to room temperature to obtain a viscous polyimide resin solution.

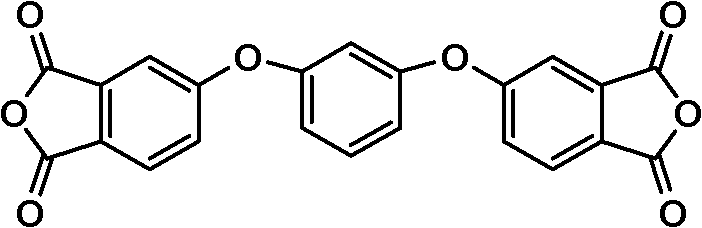

Embodiment 2

[0072] At room temperature, in a 500ml three-neck flask, add 205g of dimethylacetamide, then add 8.0g of m-phenylenediamine, 4.3g of 3,3-diaminodiphenyl ether sulfone, 4.0g of 3,4-diaminodiphenyl ether, Under the protection of nitrogen, stir at a medium speed to dissolve completely, and then gradually add 5.1g bisphenol A type diether tetraacid dianhydride, 25.0g 5-hydroxytriphenyl ether tetraacid dianhydride, 6.4g triphenylene ether tetraacid dianhydride , After adding 0.5h, stir and react for 4h, then add 0.4g of 4-hydroxyphthalic anhydride, stir and react for 2h to form a viscous polyamic acid resin solution. Mix 2g of acetic anhydride and 2g of triethylamine in 8g of dimethylacetamide, and then slowly add it into the polyamic acid resin solution with a constant pressure dropping funnel. After 0.2h, the reaction is stirred for 0.5h, and then the temperature is raised to 120°C, stirred for 2 hours and then cooled to room temperature to obtain a viscous polyimide resin soluti...

Embodiment 3

[0074] At room temperature, in a 500ml three-neck flask, add 200g of dimethylformamide and dimethylacetamide (ratio of mass and number: 60:50), and then add 6.5g of m-phenylenediamine and 4.0g of 3,4-diaminodiamine Phenyl ether, 5.1 o-diaminobisphenol A, under the protection of nitrogen, stir at medium speed to dissolve completely, then gradually add 5.1g of bisphenol A type diether tetraacid dianhydride, 20.1g of 5-hydroxytriphenyl ether tetraacid dianhydride , 12.0g benzophenone tetra-acid dianhydride, 2.2g pyromellitic dianhydride, add 0.5h, then stir and react for 4h, then add 0.5g 4-hydroxyphthalic anhydride, stir and react for 2h to form a viscous polyamic acid resin solution. Mix 2g of acetic anhydride and 2g of triethylamine in 10g of dimethylformamide, and then slowly add it into the polyamic acid resin solution with a constant pressure dropping funnel. After 0.2h, the reaction is stirred for 0.5h, and then the temperature is raised to 120°C, stirred for 2 hours and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com