Carbon fiber tent rack

A carbon fiber tube and tent technology, applied in the field of carbon fiber tent brackets, can solve the problems of long production cycle, impact on structural strength, and heavy metal tube materials, and achieve the effects of reducing erection and dismantling time, improving structural strength, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, carbon fiber tent support

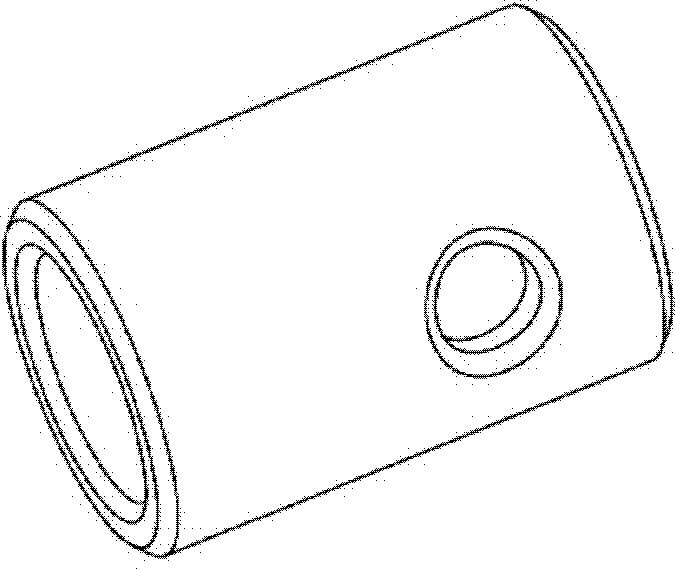

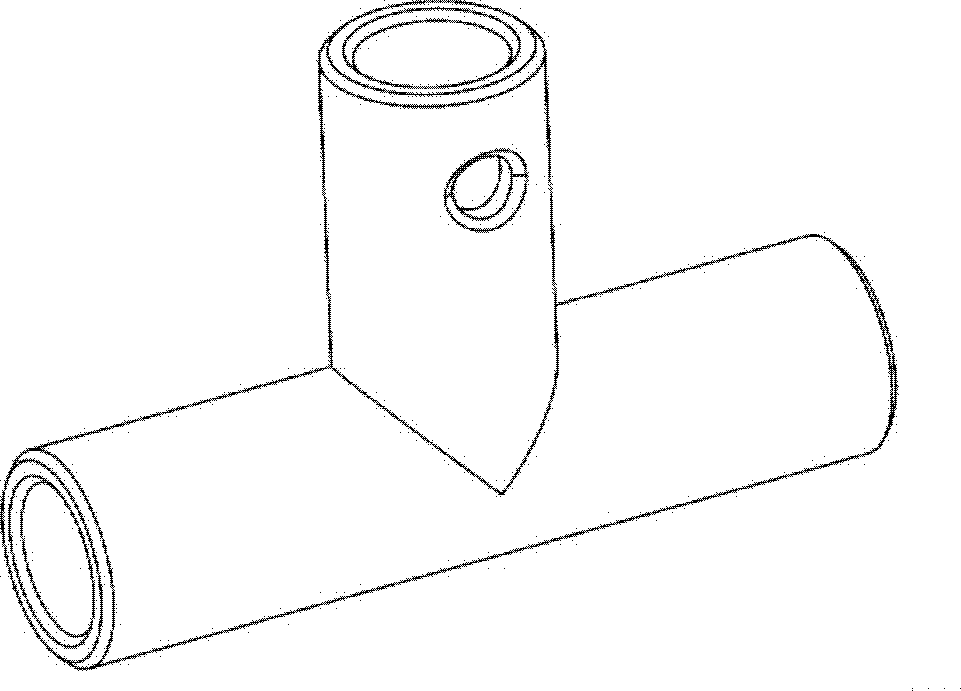

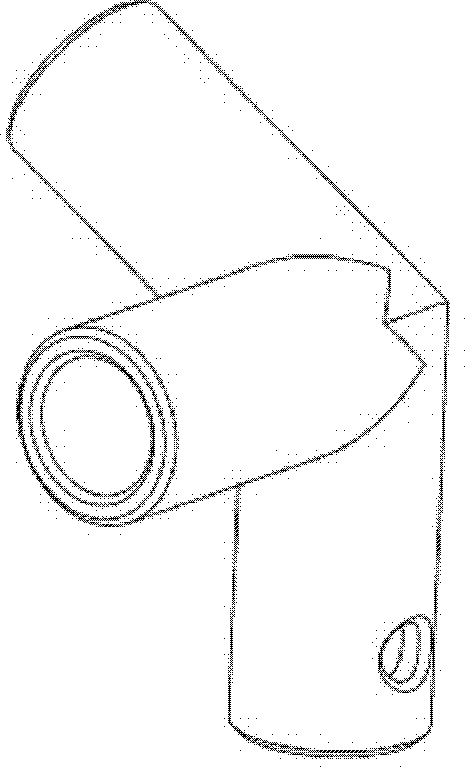

[0038] The tent frame consists of some carbon fiber tubes, some plastic (polyamide) connectors 1-6 and some screws. The tube walls at both ends of the carbon fiber tube are provided with through holes for passing through the screws, and the tube walls of at least one port edge of the connector are provided with through holes for passing through the screws, The carbon fiber tube and the connector adopt a direct plug-in connection structure and are fastened with screws;

[0039] Wherein, the outer diameter of the carbon fiber tube is 32mm, the thickness of the tube wall is 3.2mm, and the length is 1880mm; the aperture of the hole set on the tube wall at both ends of the carbon fiber tube is 3mm, and the chamfer of the hole is 45 degrees. The distance between the center of the hole and the end surface of the carbon fiber tube close to it is 30 mm.

[0040] The pipe diameter specifications of the carbon fiber pipes constituting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com