Quantitative constant-current continuous-feeding anti-scale and anti-separation device for closed wellhead

A flow-adding and anti-scaling technology, which is applied in wellbore/well parts, cleaning equipment, earthwork drilling and production, etc., can solve the problems of large loss, oil well scrapping, liquid medicine waste, etc. , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

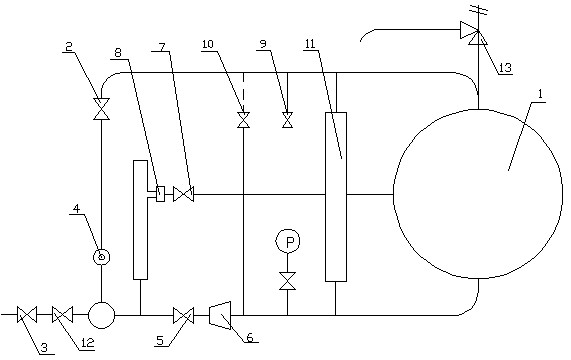

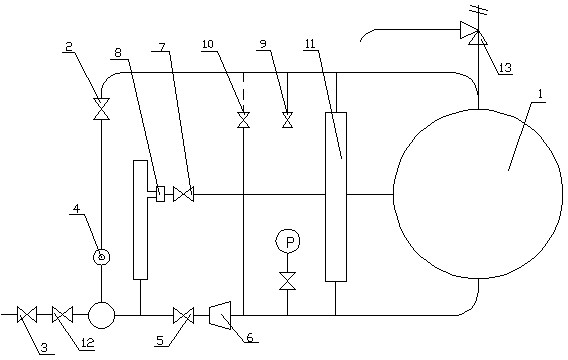

[0008] Quantitative constant flow continuous dosing anti-scaling and anti-separation device at the closed wellhead, the device is arranged between the liquid inlet pipe sleeve and the drug storage tank 1, and the outer wall and the inner wall of the drug storage tank 1 are filled with electric heating bands, The device includes a casing pressure balance valve 2, a casing gate valve 3, a constant flow dosing machine, a flow calibration valve 4, a fast dosing valve 5 and a double-position anti-scaling valve 6. The constant flow dosing machine consists of a constant flow dosing The medicine valve 7 and the constant current device 8 are composed, and the described constant current medicine dosing machine is externally connected with an electric control box. Add medicine to the medicine storage tank 1, close all outlet gate valves, open the vent valve 9 and dosing valve 10, add medicine to the medicine storage tank 1, and observe the change of the liquid level of the liquid level ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com