Self-rotating carrying frame in-place machine

A self-rotating and frame-transporting technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems of reduced work efficiency, time-consuming and labor-intensive repair of flatbed trucks, broken shafts, etc., to achieve convenient and efficient use, smooth operation of equipment, Easy and quick effect to uninstall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

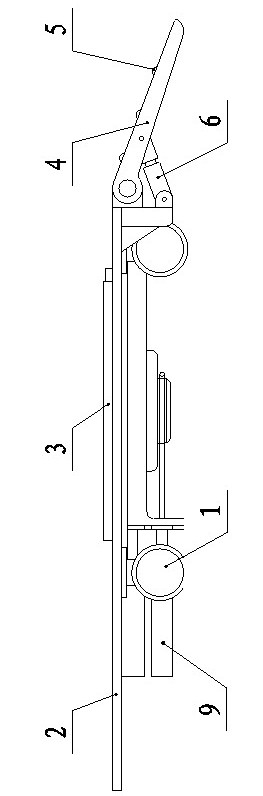

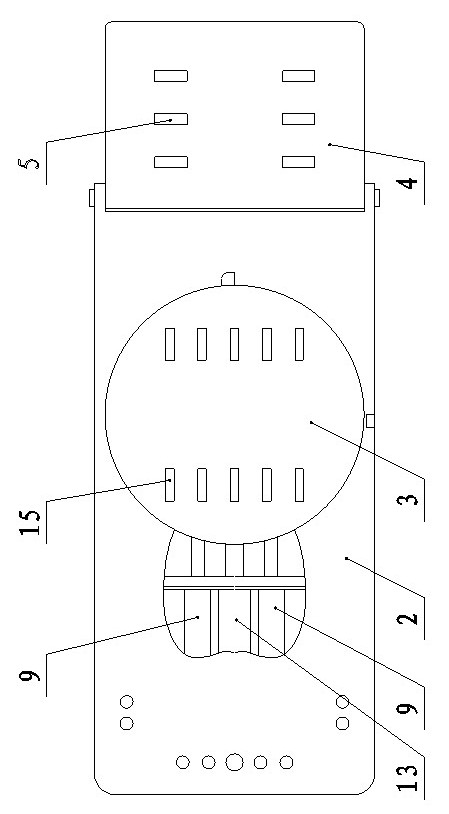

[0019] Such as figure 1 -Shown in -5, the self-rotating frame transporting machine in place of the present invention includes wheels 1, frame 2, turntable mechanism 3 and landing gear 4, a plurality of wheels 1 are installed below the frame 2, and the middle of the frame 2 is equipped with Turntable mechanism 3, one end of frame 2 is hinged with landing gear 4, two groups of first rollers 5 are arranged side by side on landing gear 4 and the top of first roller 5 is higher than the upper surface of landing gear 4, and the middle part of landing gear 4 It is hinged with the piston rod of the lifting cylinder 6, and the cylinder body of the lifting cylinder 6 is hinged at the bottom of the frame 2;

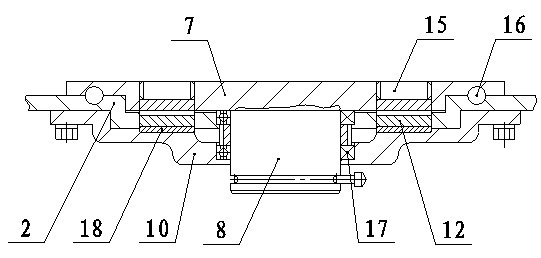

[0020] The structure of the turntable mechanism 3 is: the rotating part 7 is movably installed above the frame 2, one end of the mandrel 8 is fixed in the middle of the bottom of the rotating part 7, and the other end of the mandrel 8 extends from the hole opened on the frame 2 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com