Quick construction formwork for middle arch secondary lining of separated island type underground excavation station

A technology of separating islands and underground excavation, which is applied in the direction of shaft lining, tunnel lining, underground chamber, etc., and can solve the problems of troublesome operation, low operating efficiency, and large personnel investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

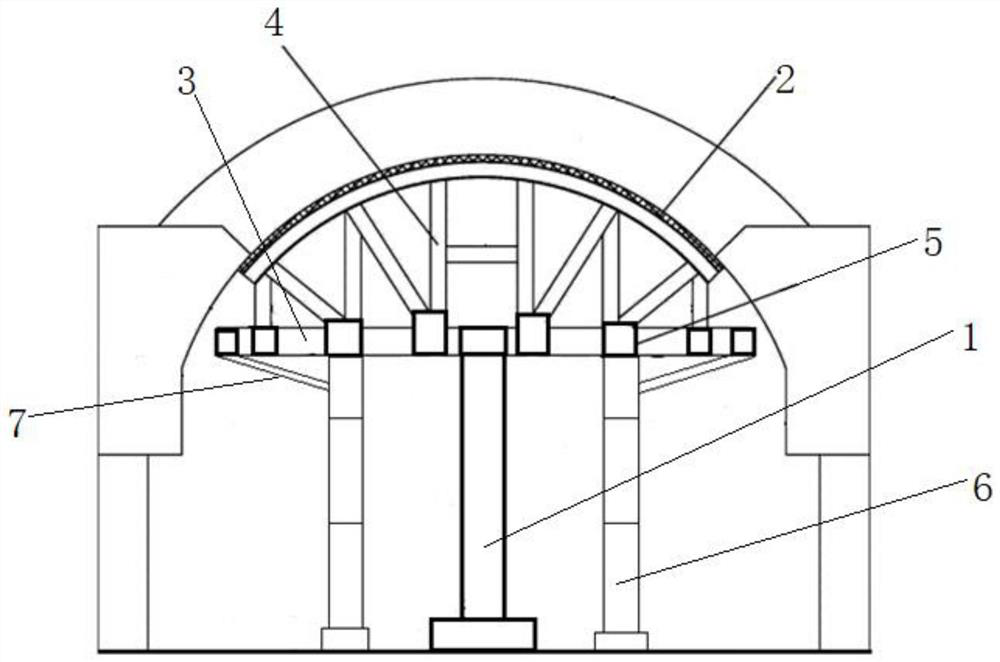

[0029] See attached figure 1 A formwork for rapid construction of the second lining of the middle arch of a separate island type underground excavation station, comprising two main support brackets 1 arranged along the depth direction of the middle arch, a support bracket supporting a formwork 2 used for the construction of the second lining of the middle arch, and Telescopic driving device arranged on the main support bracket 1; the support bracket includes a plurality of first support brackets 3 perpendicular to the main support bracket 1 and distributed horizontally, and a plurality of vertical shafts arranged on the first support bracket 3 The second support bracket 4 distributed to and obliquely upward; the main support bracket 1 includes a peripheral support bracket and an internal support bracket, and the telescopic drive device is arranged in the peripheral support bracket; the second support bracket 4 is pivoted by telescopic The structure 5 is hinged with the first s...

Embodiment 2

[0039] See attached figure 1 A formwork for rapid construction of the second lining of the middle arch of a separate island type underground excavation station, comprising two main support brackets 1 arranged along the depth direction of the middle arch, a support bracket supporting a formwork 2 used for the construction of the second lining of the middle arch, and Telescopic driving device arranged on the main support bracket 1; the support bracket includes a plurality of first support brackets 3 perpendicular to the main support bracket 1 and distributed horizontally, and a plurality of vertical shafts arranged on the first support bracket 3 The second support bracket 4 distributed to and obliquely upward; the main support bracket 1 includes a peripheral support bracket and an internal support bracket, and the telescopic drive device is arranged in the peripheral support bracket; the second support bracket 4 is pivoted by telescopic The structure 5 is hinged with the first s...

Embodiment 3

[0053] See attached figure 1 A formwork for rapid construction of the second lining of the middle arch of a separate island type underground excavation station, comprising two main support brackets 1 arranged along the depth direction of the middle arch, a support bracket supporting a formwork 2 used for the construction of the second lining of the middle arch, and Telescopic driving device arranged on the main support bracket 1; the support bracket includes a plurality of first support brackets 3 perpendicular to the main support bracket 1 and distributed horizontally, and a plurality of vertical shafts arranged on the first support bracket 3 The second support bracket 4 distributed to and obliquely upward; the main support bracket 1 includes a peripheral support bracket and an internal support bracket, and the telescopic drive device is arranged in the peripheral support bracket; the second support bracket 4 is pivoted by telescopic The structure 5 is hinged with the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com