Gear interlocking device for automotive transmission

A technology of automobile transmission and interlocking device, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve problems such as inability to interlock, large relative distance between shift fork shafts, etc., and achieve processing and precision Low requirements, flexible layout, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

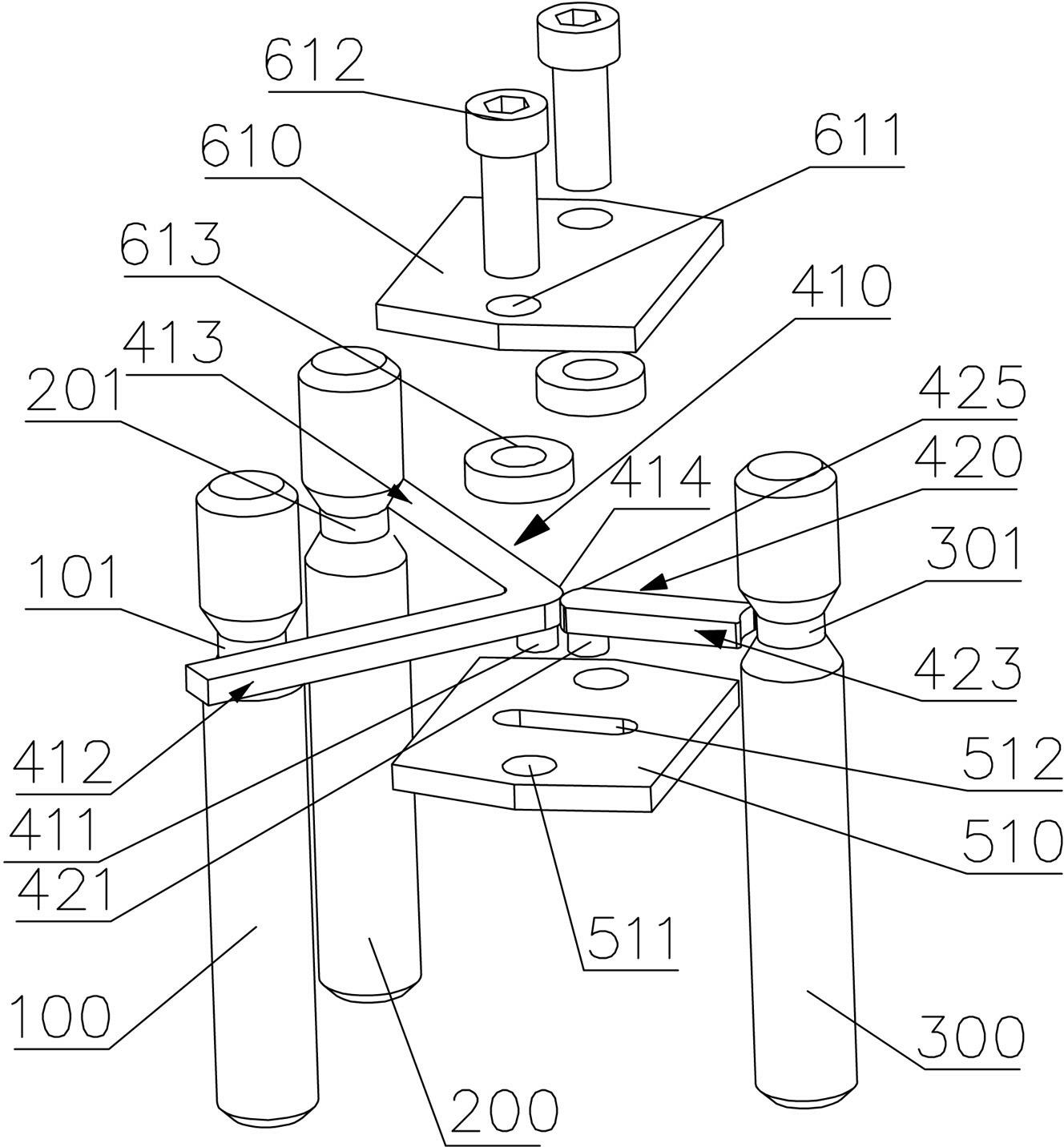

[0024] Such as figure 1 In the gear interlocking device of the automobile transmission in the embodiment shown, there are three shift fork shafts, which are arranged in parallel. Through the axial movement of the shift fork shaft, the gears on the corresponding shafts can be combined or disengaged. Recesses are respectively provided at the same position on the shaft, wherein the first shift fork shaft group includes two shift fork shafts, namely the first shift fork shaft 100 and the second shift fork shaft 200, and the second shift fork shaft group has a The first shift fork shaft, that is, the third shift fork shaft 300, the recessed part provided on each shift fork shaft is used to combine with the locking arm, thereby locking the shift fork shaft, the recessed part in this embodiment is the dial The annular slots provided on the outer wall of the fork shaft are respectively the first slot 101 provided on the first fork shaft 100, the second slot 201 provided on the second ...

Embodiment 2

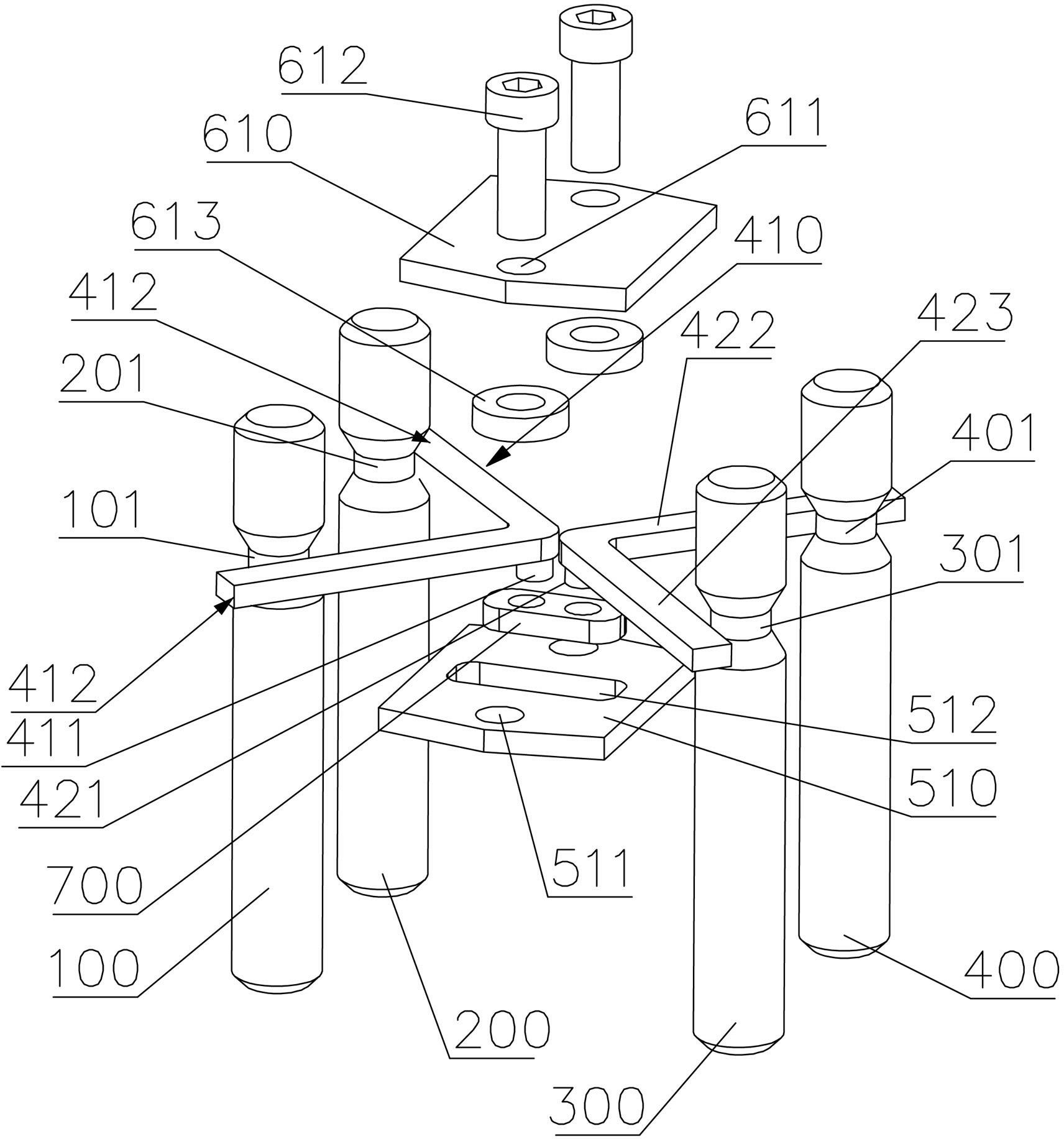

[0032] Such as figure 2 The automobile transmission gear interlocking device of this embodiment shown is different from Embodiment 1 in that this embodiment is applied to the structure of four shift fork shafts, that is, a second shift fork shaft group is also provided with a second shift fork shaft. Four shift fork shafts 400, the fourth shift fork shaft 400 is provided with a corresponding fourth slot 401, correspondingly, the second locking arm group 420 is added with a fourth locking arm 422, and the third locking arm 423 and The fourth locking arm 422 is rigidly connected and has a V shape as a whole. The fourth locking arm 422 can be embedded in the fourth slot 401 to lock the axial movement of the fourth fork shaft 400 . The third locking arm 423 and the fourth locking arm 422 are also combined on the outer side of the second shift fork shaft group.

[0033] In addition, in order to reflect the improvement of the present invention, in this embodiment, a sliding block ...

Embodiment 3

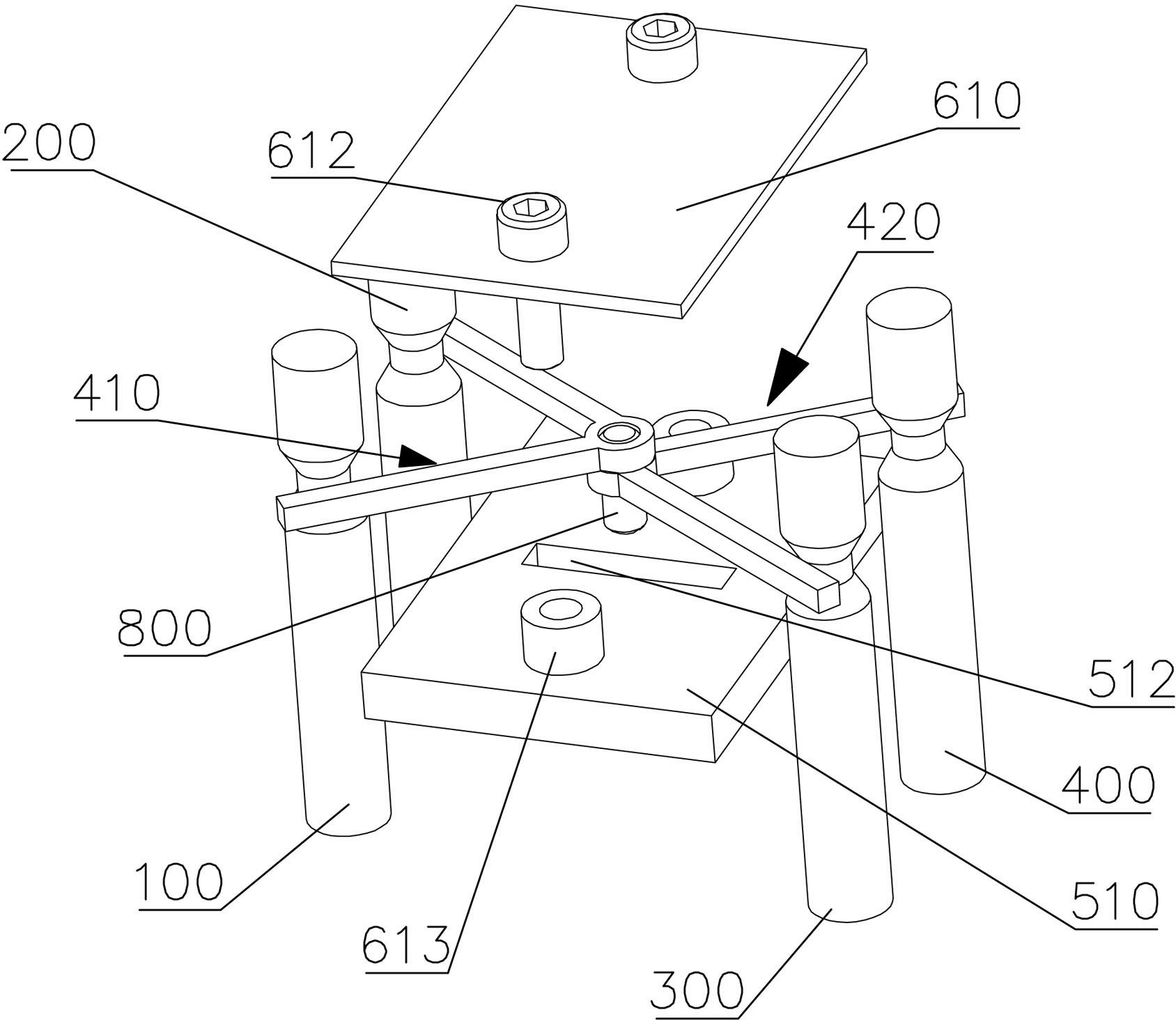

[0037] Such as image 3 The gear interlocking device of the automobile transmission shown in this embodiment is different from the second embodiment in that no slider is added, and the first locking arm group 410 and the second locking arm group 420 are equipped with A through hole, the pin shaft 800 passes through the through hole to form a mutual rotatable connection between the two, and the boss at the front end of the pin shaft enters into the slide groove 512 to form a sliding fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com