Automatic scanning device for monitoring coal yard

A technology of automatic scanning and scanning devices, which is applied in the direction of measuring devices, instruments, thermometers, etc., can solve the problems of high construction safety level, low work efficiency, hot-fire welding, etc., and achieve convenient later maintenance, simple construction and debugging, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

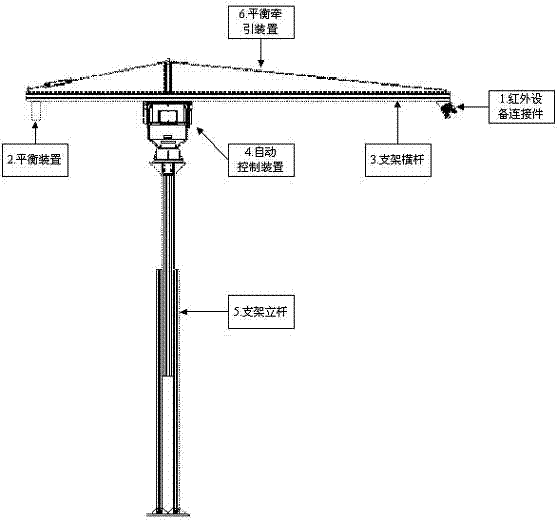

[0035] Such as figure 1 shown.

[0036] An automatic scanning device for coal yard monitoring, which includes:

[0037] A scanning device 1, the scanning device 1 is installed on the long cantilever end of the bracket cross bar 3 through a connecting piece, and the scanning device includes one of an infrared scanner, a laser scanner, an infrared thermal imager, and the like. ;

[0038] A balance fitting 2, the balance device 2 is used to counterweight the scanning device 1, which can be realized by one of counterweight block, counterweight iron, counterweight ore, counterweight iron sand, etc.;

[0039] A bracket bar 3, the two ends of the bracket bar 3 are respectively installed with a scanning device 1 and a balancer 2 and can be wired;

[0040] A rotating device 4, the rotating device 4 is used to drive the bracket cross bar 3 to rotate 360 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com