Six-post type three-dimensional visual detection system for automobile wheel alignment parameters

A technology for wheel positioning and three-dimensional parameters, which is applied in wheel testing, measuring devices, instruments, etc., can solve the problems of being unsuitable for large-scale promotion, low manufacturing cost, and high manufacturing cost, and achieve low production cost, low manufacturing cost, and mechanical processing. The effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

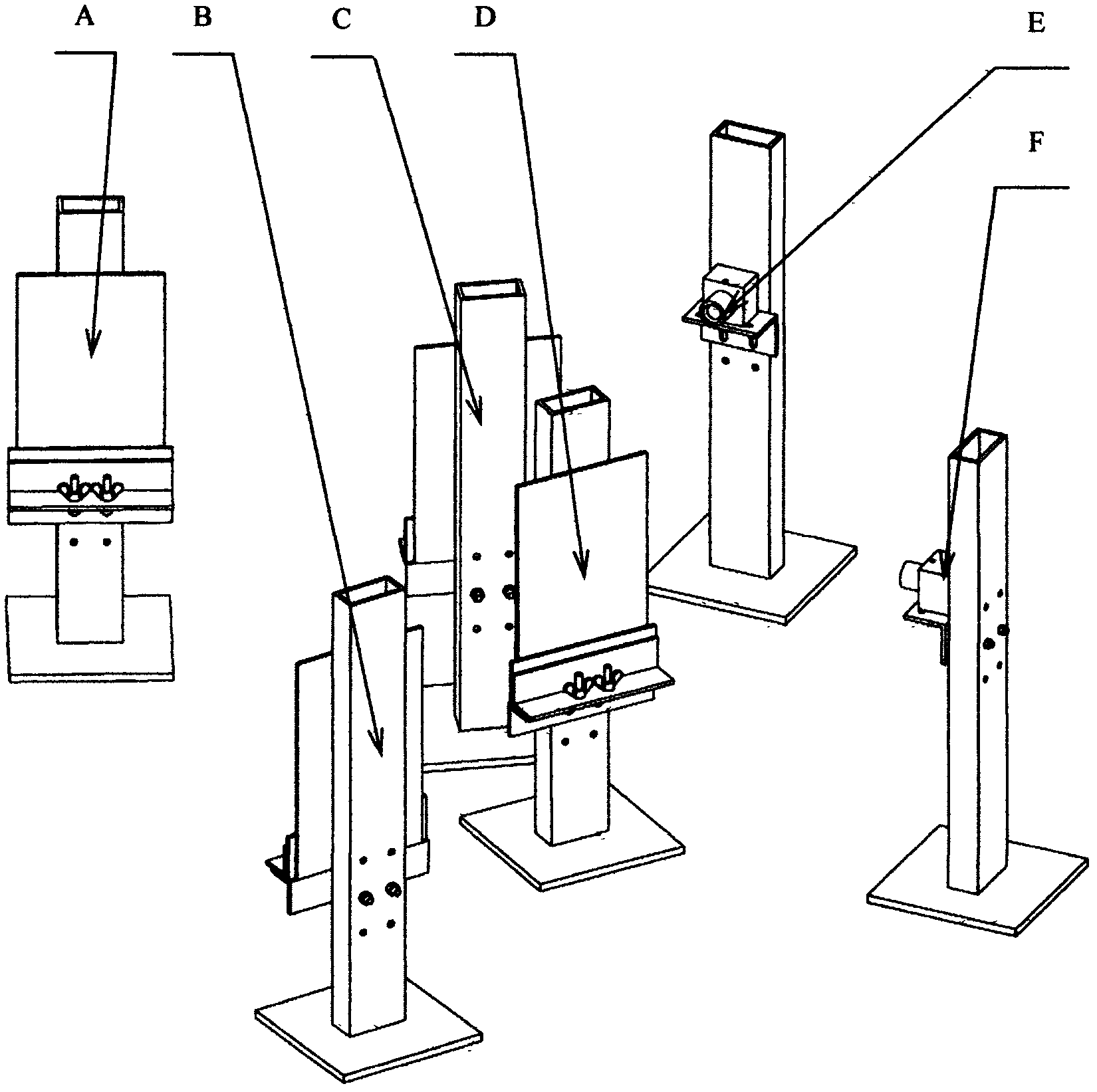

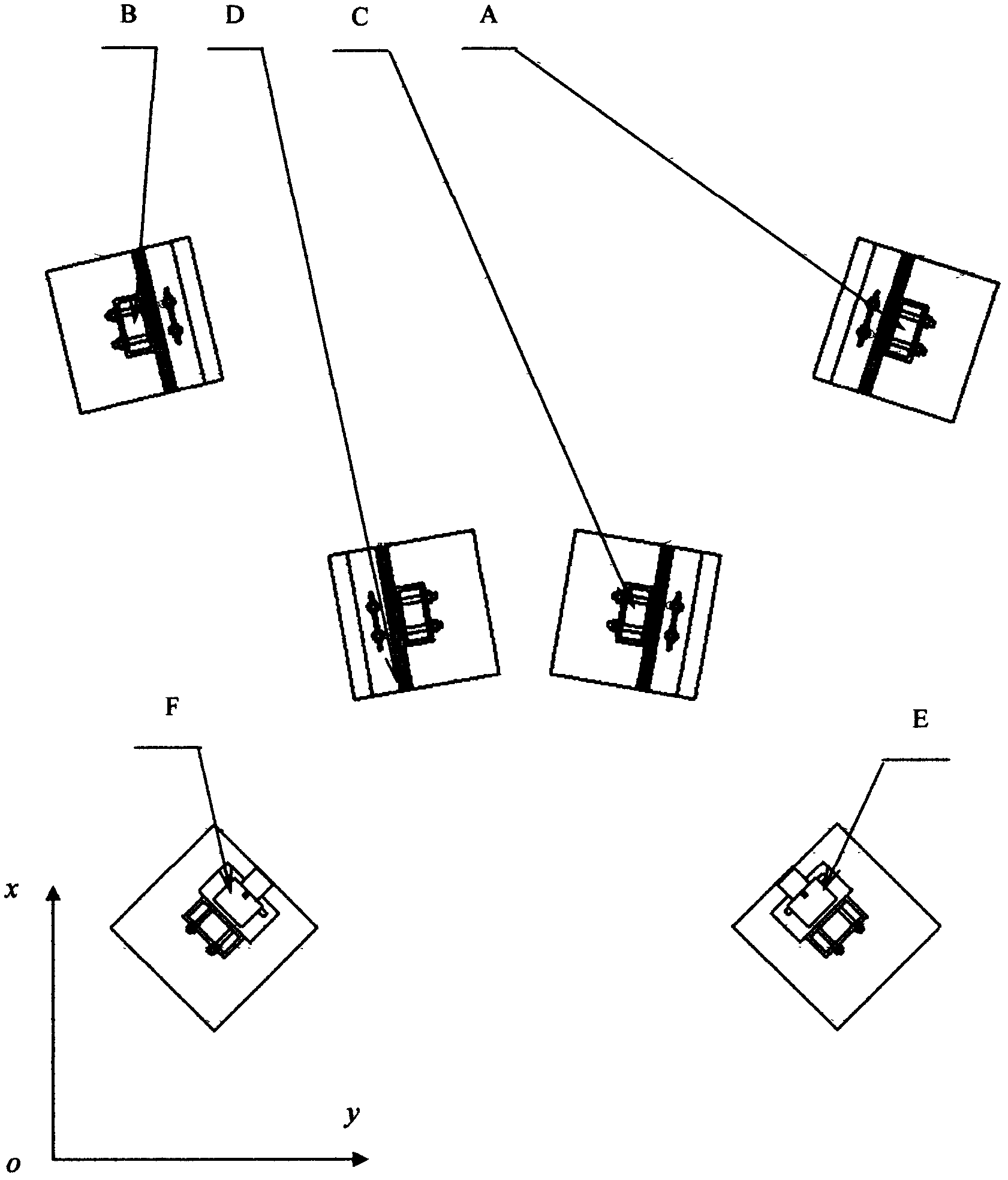

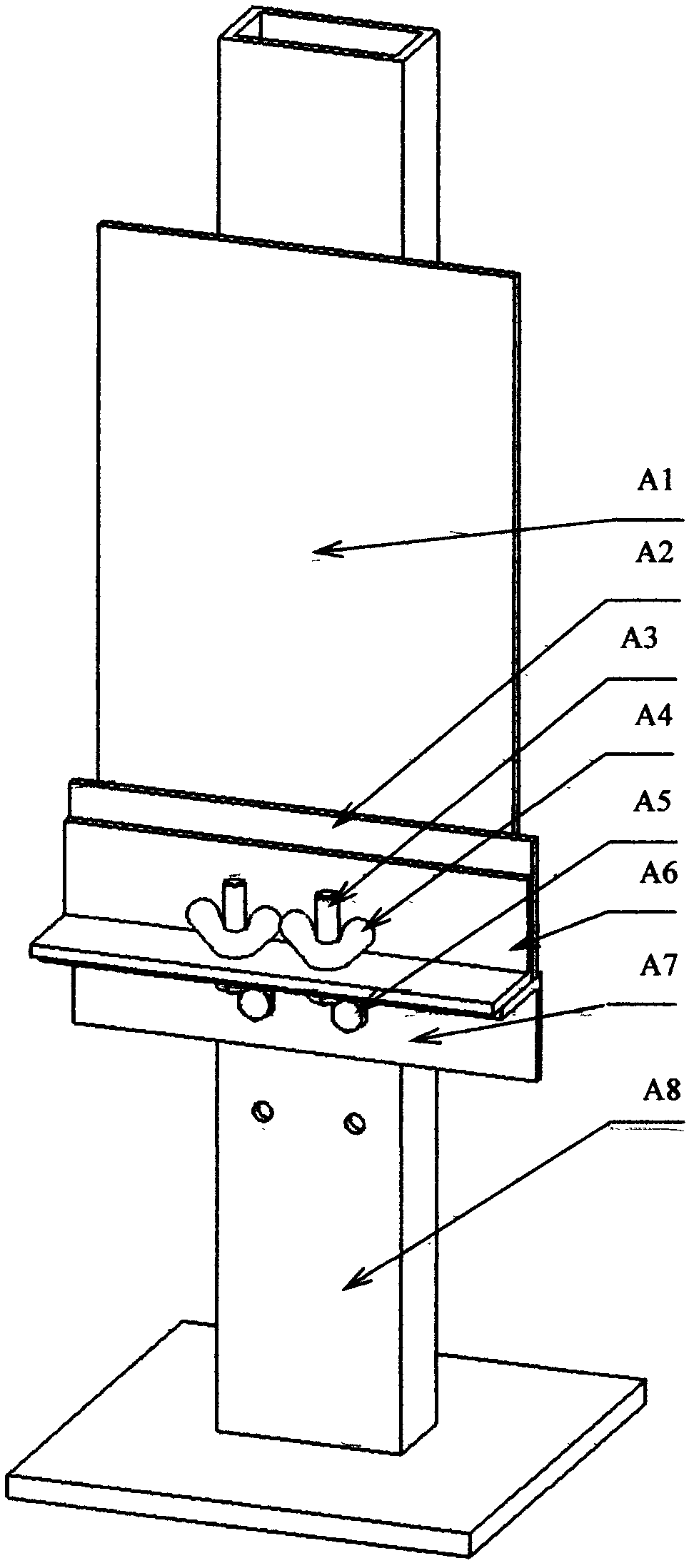

[0032] refer to Figure 1 to Figure 6 The six-column car wheel alignment parameter stereo vision detection system consists of a front right plane mirror quick clamping and positioning device A, a front left plane mirror quick clamping and positioning device B, a rear right plane mirror quick clamping and positioning device C, and a rear left plane mirror quick clamping and positioning device The device D, the camera installation system F with adjustable left position and the camera installation system E with adjustable right position are composed.

[0033] The fast clamping and positioning device A of the front right plane mirror, the fast clamping positioning device B of the front left plane mirror, the fast clamping positioning device C of the rear right plane mirror and the fast clamping positioning device D of the rear left plane mirror are exactly the same in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com