Measurement device for thermal shrinkage ratio of pull wire

A measuring device and technology of thermal shrinkage rate, applied in the direction of material thermal expansion coefficient, etc., can solve problems such as difficult to accurately measure size, easy to wrinkle, twist, narrow width, etc., to avoid heat loss, fast action, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

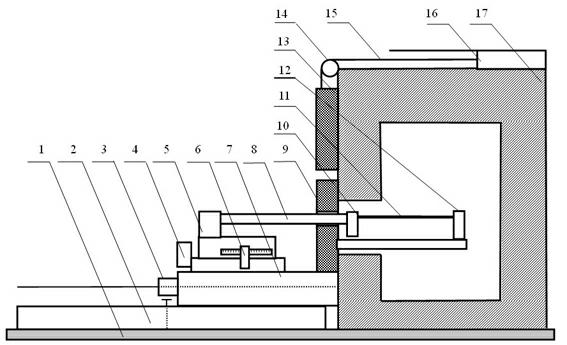

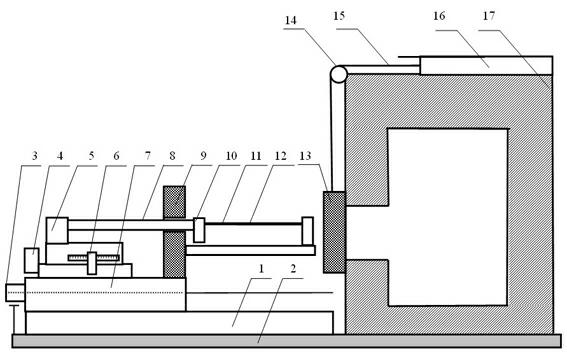

[0039] Such as figure 1 As shown, a measuring device for the heat shrinkage rate of a cable includes a measuring unit, an oven movable door lifting unit and an oven. The measuring unit includes a guide rail 2, a rodless cylinder 3, an electric platform 4, a tension sensor 5, a displacement sensor 6, and a fixed plate 7. Connecting rod 8, oven fixed door 9, left fixture 10 and right fixture 12;

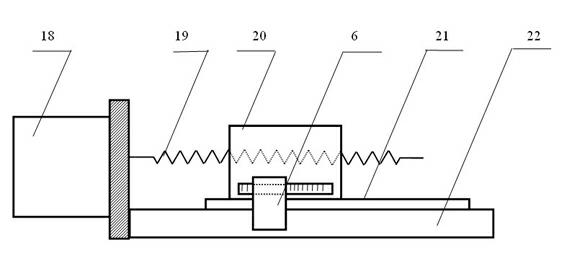

[0040] Electric platform 4 reference image 3 Set up, comprise stepping motor 18, platform fixed block 22, platform moving block 20, leading screw 19 and precision guide rail 21, stepping motor 18 is fixed on the platform fixing block 22, drives platform moving block 20 by leading screw 19 in precision Slide on the guide rail 21;

[0041] The fixed plate 7 is fixed on the slider of the rodless cylinder 3, the platform fixed block 22 and the oven fixed door 9 are fixed on the fixed plate 7, the guide rail 2 is fixed on the bottom of the fixed plate 7, both sides of the rodless cylinde...

Embodiment 2

[0048] The device constructed in Example 1 was used to perform the heat shrinkage test of the drawn wire.

[0049] First, the oven movable door 13 seals the oven door hole, and the oven temperature rises to a set value. Clamp one end of the pull wire 11 on the right clamp 12, and clamp the other end on the left clamp 10. At this time, the initial distance of the system is L 0 (Theoretically, this position is 100mm according to the industry standard). The electric platform 4 moves away from the clamp to make the pull wire 11 subject to tension. When the measured value of the tension sensor 5 reaches the specified value, the displacement sensor 6 records the displacement L of the electric platform 4 1 , calculate the original length L=L of the guy wire 11 0 + L 1 .

[0050] Then the electric platform 4 drives the left clamp 10 to move a certain distance towards the direction close to the clamp, so that the stay wire 11 is in a relaxed state. The air cylinder 16 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com