Freshly mixed concrete comprehensive determinator and manufacturing method and determining method thereof

A concrete and measuring instrument technology, which is applied in the direction of instruments, material inspection products, and analytical materials, can solve problems such as inability to discover construction deficiencies, hysteresis, and inability to adjust construction processes in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

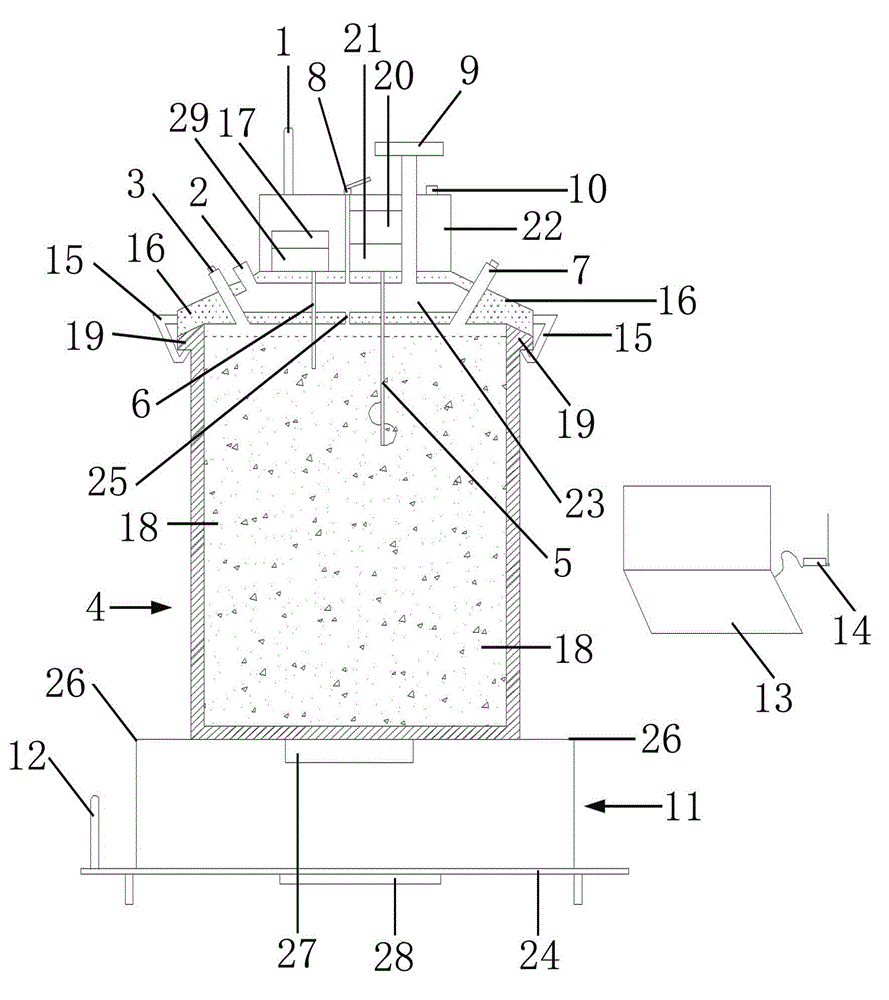

[0086] It is composed of a balance (11), a measurement and detection container (4), a sealing cover (16), a detection facility (22), a data information acquisition controller (17) and a main controller (13). The balance (11) is composed of A weighing pan (26), a balance data information collector (28), a load cell (27), a balance base (24) and a balance data transmitter (12), the balance base (11) is set at the bottom Seat (24), the scale base (24) carries the whole scale (11), the top of the scale (11) is a weighing pan (26), and the weighing detection container (4) is carried on the weighing pan (26). (11) The balance data information collector (28) and the load cell (27) are installed inside, the weighing pan (26) is connected with the load cell (27), and the load cell (27) detects the measurement container (4 ) weight on the weighing pan (26), the balance data information collector (28) and the load cell (27) are connected with the power supply (29) through the line, and t...

Embodiment 2

[0088] The measuring and detecting container (4) is placed on the weighing pan (26) on the upper part of the balance (11), the bottom of the measuring and detecting container (4) coincides with the weighing pan (26) of the balance (11), and the measuring and detecting container (4 ) is in the shape of a barrel as a whole, with blind holes, and the outer wall of the upper end of the measurement and detection container (4) is provided with an upper flange (19), and the upper flange (19) coincides with the buckle lock (15), which is conducive to the closure of the buckle lock (15) The metering and testing container (4), and the measured fresh concrete (18) is placed in the metering and testing container (4), such as figure 1 shown.

Embodiment 3

[0090] A sealing cover (16) is placed on the upper part of the measuring and testing container (4), and the sealing cover (16) coincides with the upper port of the measuring and testing container (4), and the sealing cover (16) seals the upper port of the measuring and testing container (4) for testing , the air chamber (23) is set in the sealing cover (16), the air chamber (23) is closed as a whole, the air chamber (23) is provided with a vent hole (25), and the vent hole (25) runs through the bottom of the sealing cap (16) and measures The detection container (4) is connected, and the water injection hole (7), the drainage hole (3) and the air pressure sensor (2) are installed on the sealing cover (16). The water injection hole (7) and the drainage hole (3) are cylindrical, and the water injection hole (7) and the drain hole (3) run through the bottom of the sealing cover (16), and the upper port of the water injection hole (7) and the drain hole (3) can be opened and closed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com