Optical fiber power frequency electric field sensor

A technology of power frequency electric field and optical fiber electric field, applied in electrostatic field measurement and other directions, can solve the problems of high cost, troublesome use and operation, sensor sensitivity easily affected by temperature, etc., and achieve the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

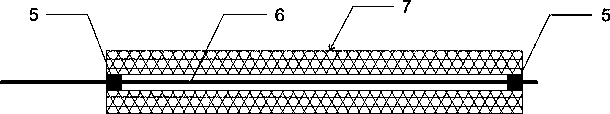

[0046] see figure 1 1. The optical fiber power frequency electric field sensor includes an electric field sensitive element and an insulating package, and is characterized in that: the electric field sensitive element is a first type optical fiber electric field sensitive element or a second type optical fiber electric field sensitive element.

Embodiment 2

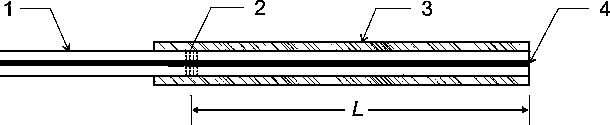

[0048] see figure 1 and figure 2 , this embodiment is basically the same as Embodiment 1, and the special feature is: the first type of optical fiber electric field sensitive element is: a single-mode optical fiber is written into a fiber grating to form a fiber internal grating wavelength reflector, separated by a distance of After the length is fixed, the single-mode optical fiber is cut off, the cross section is flat and ground, and an external reflector is formed by coating, thereby forming a fiber F-P resonant cavity with a single grating + reflector, and the surface of the optical fiber with a fiber F-P resonant cavity is coated with a polymer resin layer.

Embodiment 3

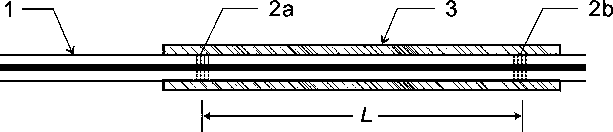

[0050] refer to figure 1 and image 3 , this embodiment is basically the same as Embodiment 1, and the special feature is: the optical fiber power frequency electric field sensor is characterized in that: the second type of optical fiber electric field sensitive element is: write two A fiber grating forms a double-grating fiber F-P resonant cavity, and a polymer resin layer is coated on the surface of the fiber with the double-grating fiber F-P resonant cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com