Point contact fiber optic ultrasonic sensor

An ultrasonic and sensor technology, applied in the field of measurement, can solve the problems of staying at the highest response frequency, unsatisfactory high-frequency ultrasonic response characteristics, reduced sensor sensitivity, etc., to achieve the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

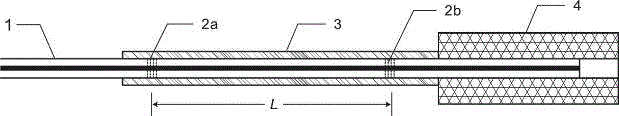

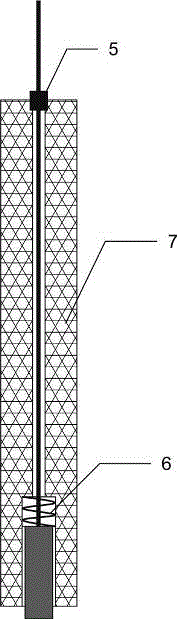

[0046] Referring to Fig. 1 and Fig. 2, this point-contact optical fiber ultrasonic sensor includes a core part and a package shell, and is characterized in that: the core part is made of an optical fiber ultrasonic sensitive element; the package shell is an electrical insulation shell; the fiber optic ultrasonic sensor Sensitive elements are encapsulated in the electrical insulation shell to form a single sensor.

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, and the special features are:

[0049] The optical fiber ultrasonic sensitive element consists of a single-mode optical fiber coated with a polyimide resin film on the surface, an optical fiber F-P resonant cavity formed by two spaced fiber gratings, and a ceramic plug glued together with the head of the single-mode optical fiber. Core composition.

[0050] The packaging structure in which the sensitive element of the optical fiber sensor is encapsulated in the electrical insulation shell applies effective stress to the optical fiber F-P resonant cavity in advance, so that the sensor has the function of sensing high-frequency ultrasonic waves.

[0051] The inner end surface of the ceramic ferrule is supported by a plastic spring, and the plastic spring is installed in the inner hole of the packaging shell in a compressed state, and applies effective stress to the optical fiber F-P resonant cavity in advance.

Embodiment 3

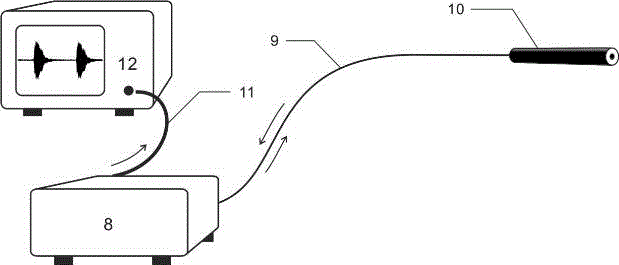

[0053] The fiber optic ultrasonic measurement system related to the embodiment of the present invention as shown in Fig. 2(a) is used as an example below to illustrate the measurement of the ultrasonic signal propagating in the surface layer of the metal flat plate by using the point contact optical fiber ultrasonic sensor of the present invention.

[0054] For example, a point-contact fiber optic ultrasonic sensor 10 can be formed by using the fiber optic ultrasonic sensor shown in FIG. 1( a ) and the package structure of the sensor shown in FIG. 1( b ).

[0055] For example, using the fiber optic ultrasonic sensor shown in Figure 1(a), the center wavelength of the two fiber gratings 2a and 2b is 1552.3nm, the line width is 1.8nm, the reflectivity is 10%, and the fiber F-P resonant cavity length L The surface is coated with a single-layer polyimide resin film, and the ceramic ferrule is the fiber optic connector material, with an outer diameter of 2.5mm and a length of 10.5mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com