Asynchronous starting permanent magnet synchronous motor rotor with tangent magnetic circuit

A technology of asynchronous starting and permanent magnet synchronization, which is applied in the field of motors and can solve problems such as low strength and large magnetic flux leakage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

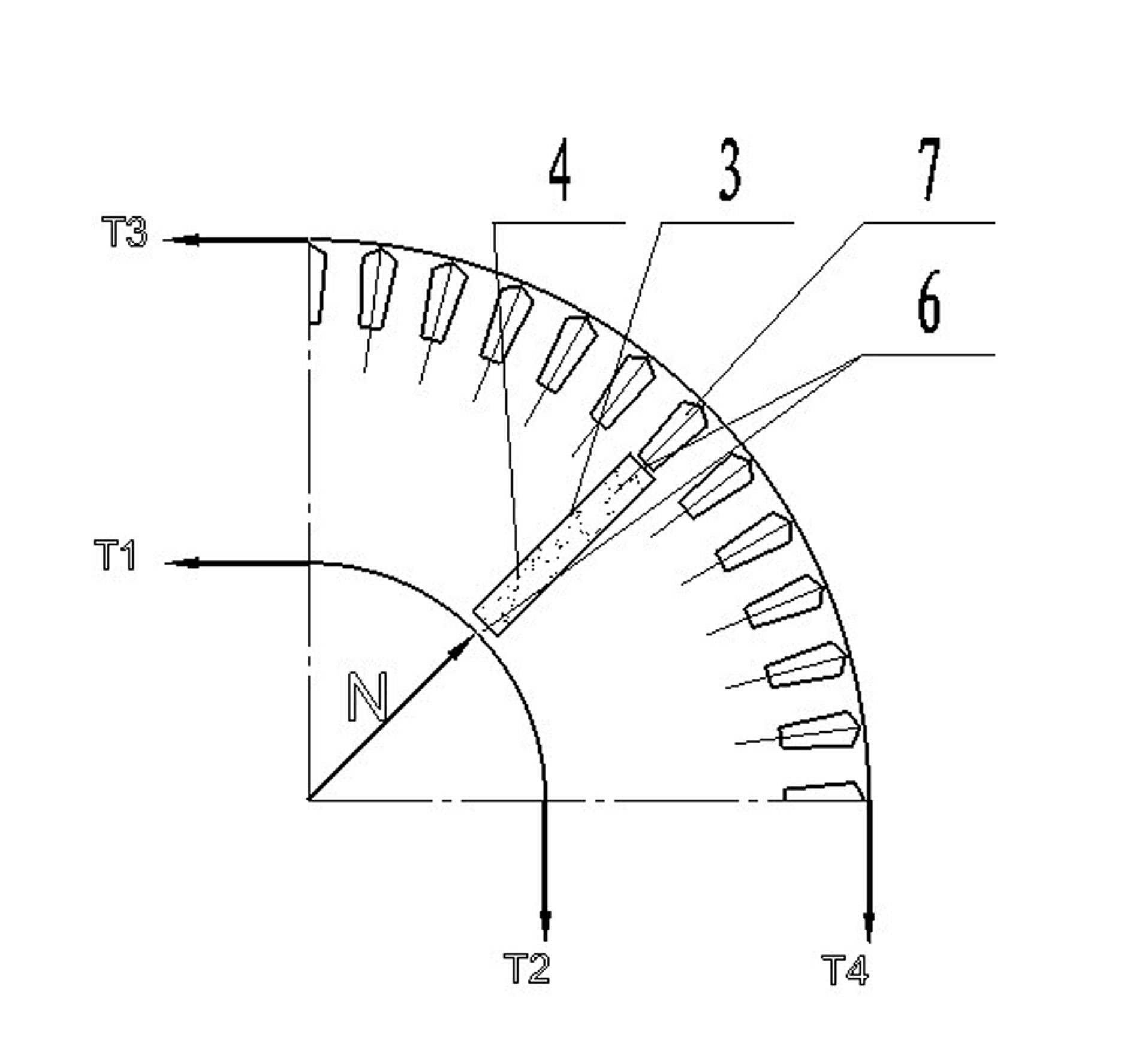

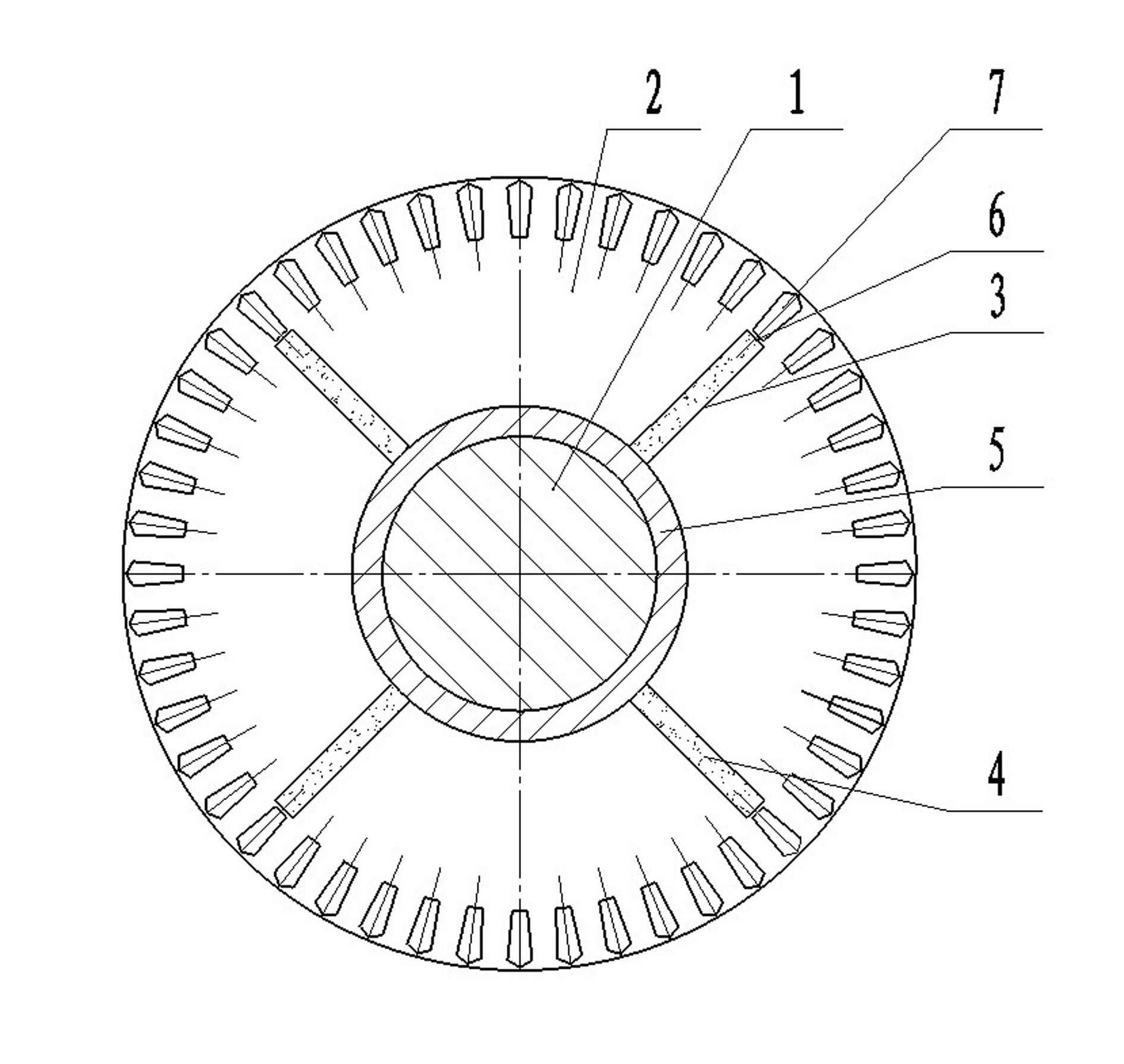

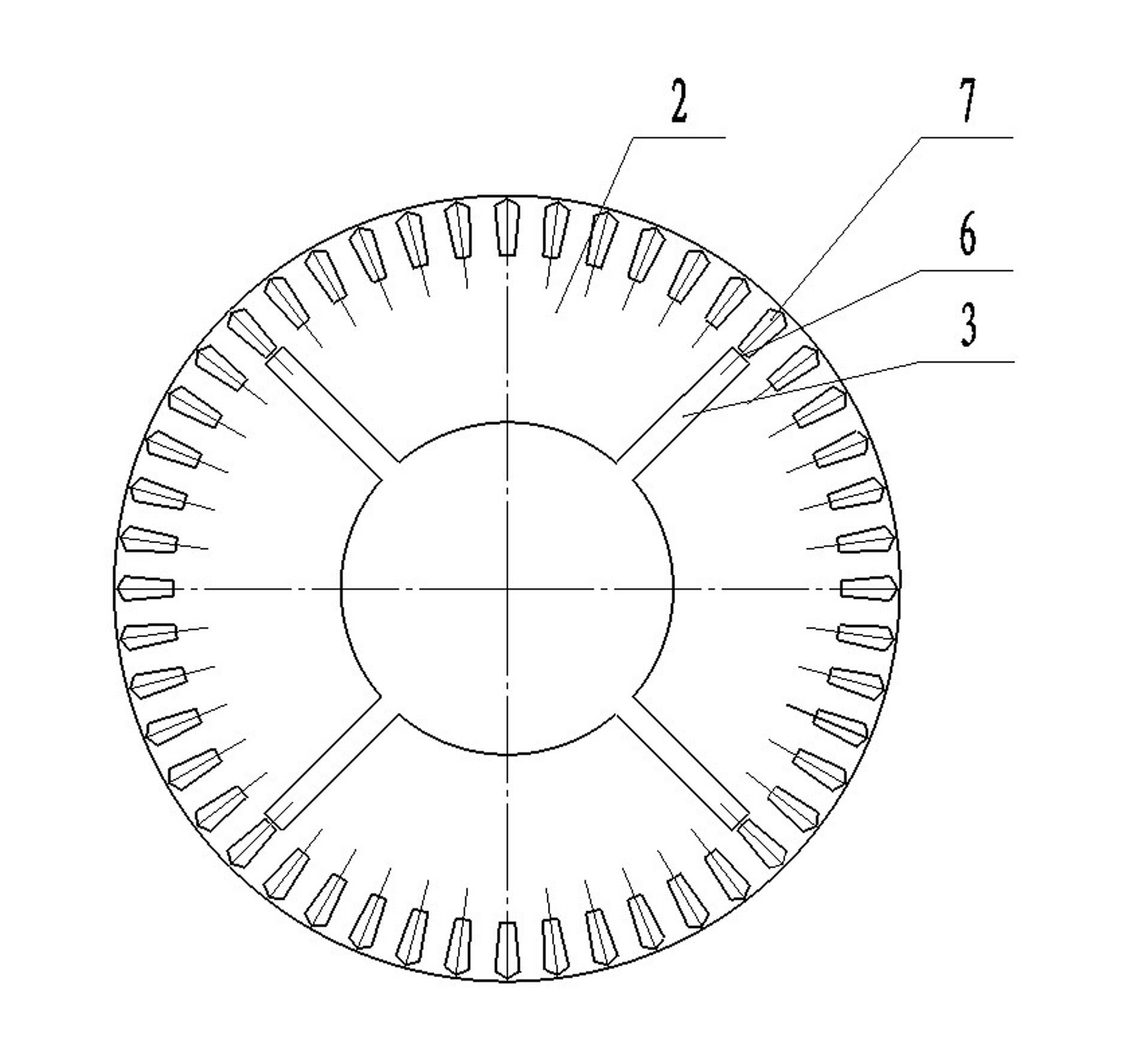

[0012] A permanent magnet synchronous motor rotor with tangential magnetic circuit asynchronous start, including a steel shaft 1 and a cast aluminum squirrel cage rotor 2; an even number of radial rectangular permanent magnet slots 3 are evenly distributed on the cross section of the cast aluminum squirrel cage rotor 2; A rectangular permanent magnet 4 is installed in the magnet slot 3; a non-magnetic sleeve 5 is pressed on the surface of the steel shaft 1; the inner ring of the cast aluminum squirrel cage rotor 2 is pressed on the outer surface of the non-magnetic sleeve 5; There are several squirrel cage grooves 7 evenly distributed in the ring; each radial rectangular permanent magnet groove 3 is corresponding to one of the squirrel cage grooves 7, and an even number of spacers is formed between the top of the radial rectangular permanent magnet groove 3 and the bottom of the squirrel cage groove 7. The magnetic bridge 6; the inner end of each radial rectangular permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com