Inverter and application circuit in three-phase system

An inverter and bridge circuit technology, applied in the field of transformerless photovoltaic grid-connected inverter and its application circuit in three-phase system, can solve the problems of complex control method, difficulty in midpoint balance control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

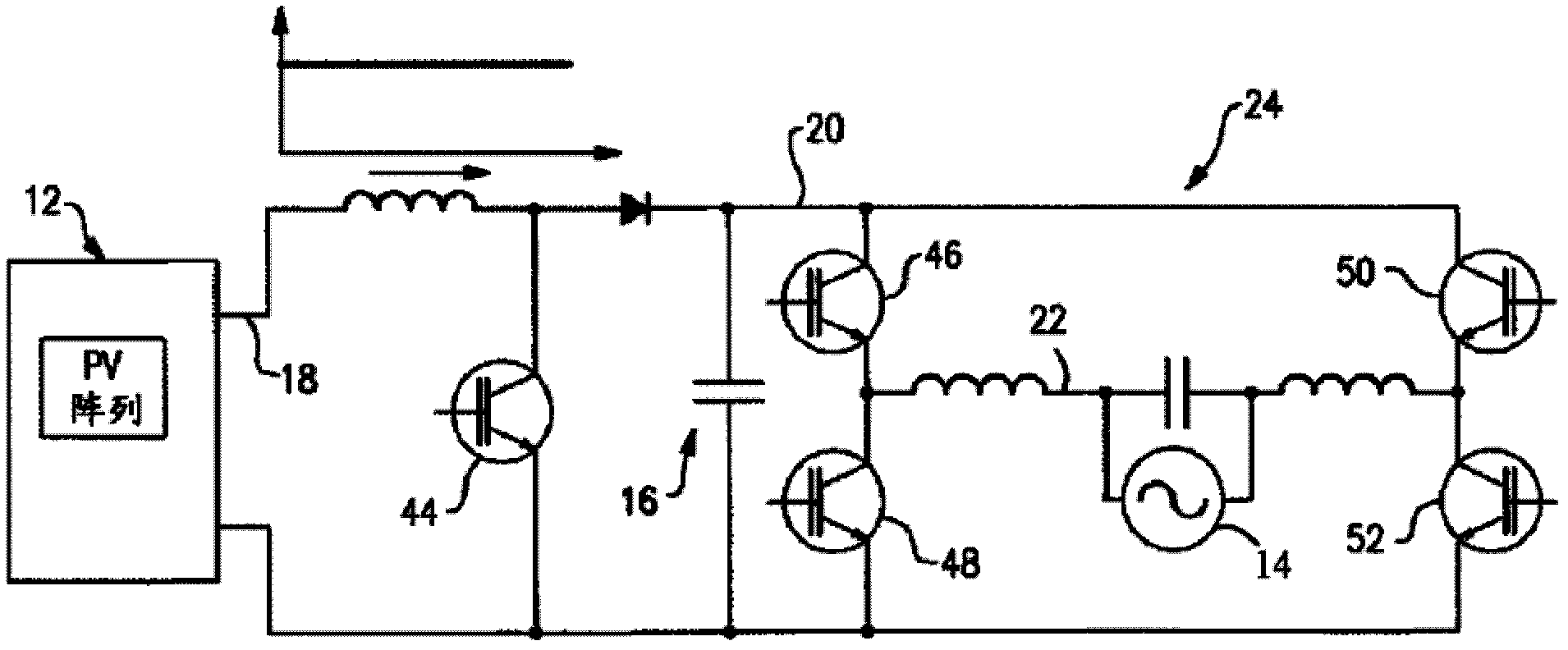

[0117] see Figure 4 , The embodiment of the present invention provides an inverter, including a DC / DC converter, capacitors C1, C2, three power switch tubes T1, T2, T7 connected in series, and an H-bridge circuit.

[0118] The input end and the ground end of the DC / DC converter are respectively connected to two ends of the DC power supply.

[0119] The capacitor C2 is connected between the positive and negative output terminals of the DC power supply, and the capacitor C1 is connected between the positive output terminal of the DC / DC converter and the negative output terminal of the DC power supply.

[0120] A diode D1, D2, D7 is respectively anti-parallel connected to the power switch tubes T1, T2, T7, the collector of the power switch tube T1 is connected to the positive output terminal of the DC power supply, and the collector of the power switch tube T7 is connected to the DC / DC converter The positive output terminal of the power switch tube T1 is connected to the collec...

no. 2 example

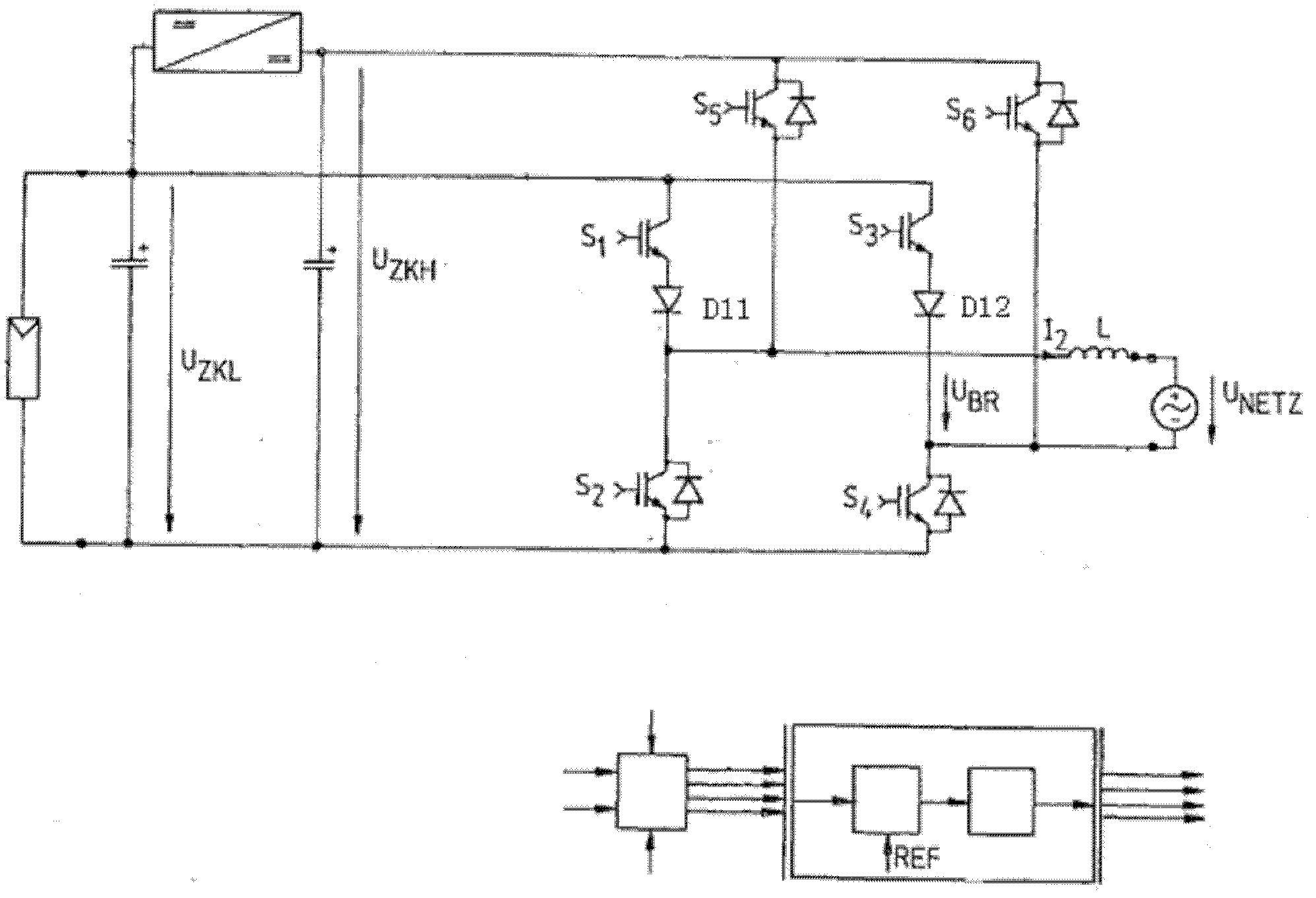

[0160] Figure 12 It is the main circuit of the second embodiment of the present invention, which has the same components as the above-mentioned first embodiment. Dual topology of an embodiment. Its specific structure is as follows.

[0161] Both the input terminal and the ground terminal of the DC / DC converter are connected to the positive output terminal of the DC power supply.

[0162] The capacitor C2 is connected between the positive and negative output terminals of the DC power supply, and the capacitor C1 is connected between the negative output terminal of the DC / DC converter and the positive output terminal of the DC power supply.

[0163] The power switch tubes T1, T2, and T7 are respectively anti-parallel connected with a diode D1, D2, D7, the emitter of the power switch tube T7 is connected to the negative output terminal of the DC / DC converter, and the emitter of the power switch tube T2 is connected to the DC power supply The negative output terminal of the po...

no. 3 example

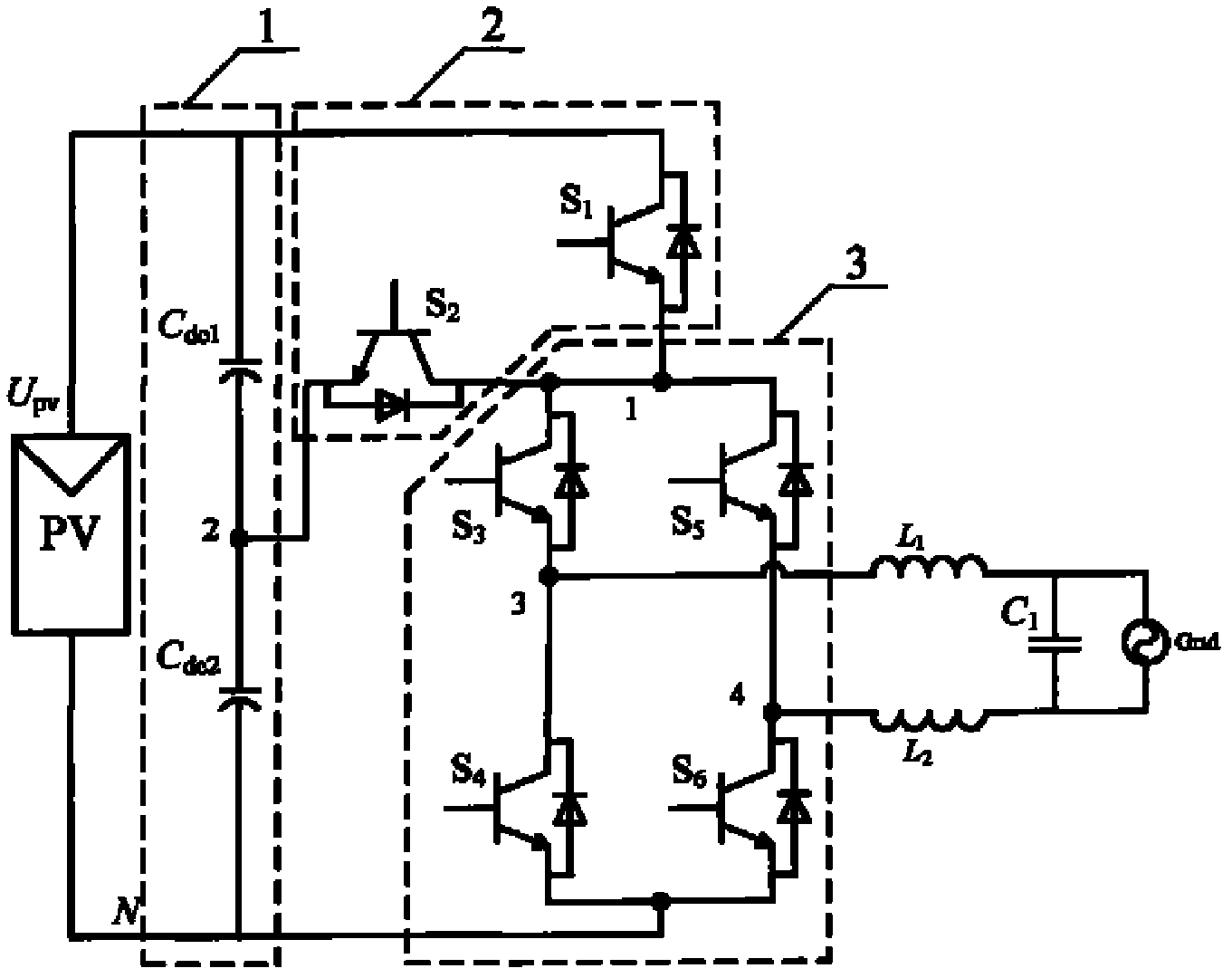

[0193] see Figure 19 , the difference between this embodiment and the first embodiment is that one power switch tube T2 is missing, and the structures of other parts are the same.

[0194] see Figure 20a to Figure 20h , the working mode analysis of the inverter in this embodiment is as follows:

[0195] Mode H1: The switching tubes T3, T6, and T7 are turned on, and the rest are turned off. Current through: DC+→T7→D2→T3→L1→Vgrid→L2→T6→PV-, bridge arm output voltage Vab=V1.

[0196] Mode H3: Switch tubes T4, T5, and T7 are turned on, and the rest are turned off. Current through: DC+→T7→D2→T5→L2→Vgrid→L1→T4→PV-, bridge arm output voltage Vab=-V1.

[0197] Mode H5: The switch tubes T1, T3, and T6 are turned on, and the rest are turned off. The current passes through: PV+→T1→T3→L1→Vgrid→L2→T6→PV-, the bridge arm output voltage Vab=V2.

[0198] Mode H6: The switch tubes T1, T3, and T6 are turned on, and the rest are turned off. The current passes through: PV-→D6→L2→Vgrid→L1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com