Initial starting method for double-shaft contra-rotating permanent magnet brushless direct current motor

A permanent magnet brushless DC, a pair of technology, applied in the direction of the starting device, etc., can solve the problems of large commutation error, unable to start the motor reliably, etc., to improve operating efficiency, no starting dead zone problem, accurate angle calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

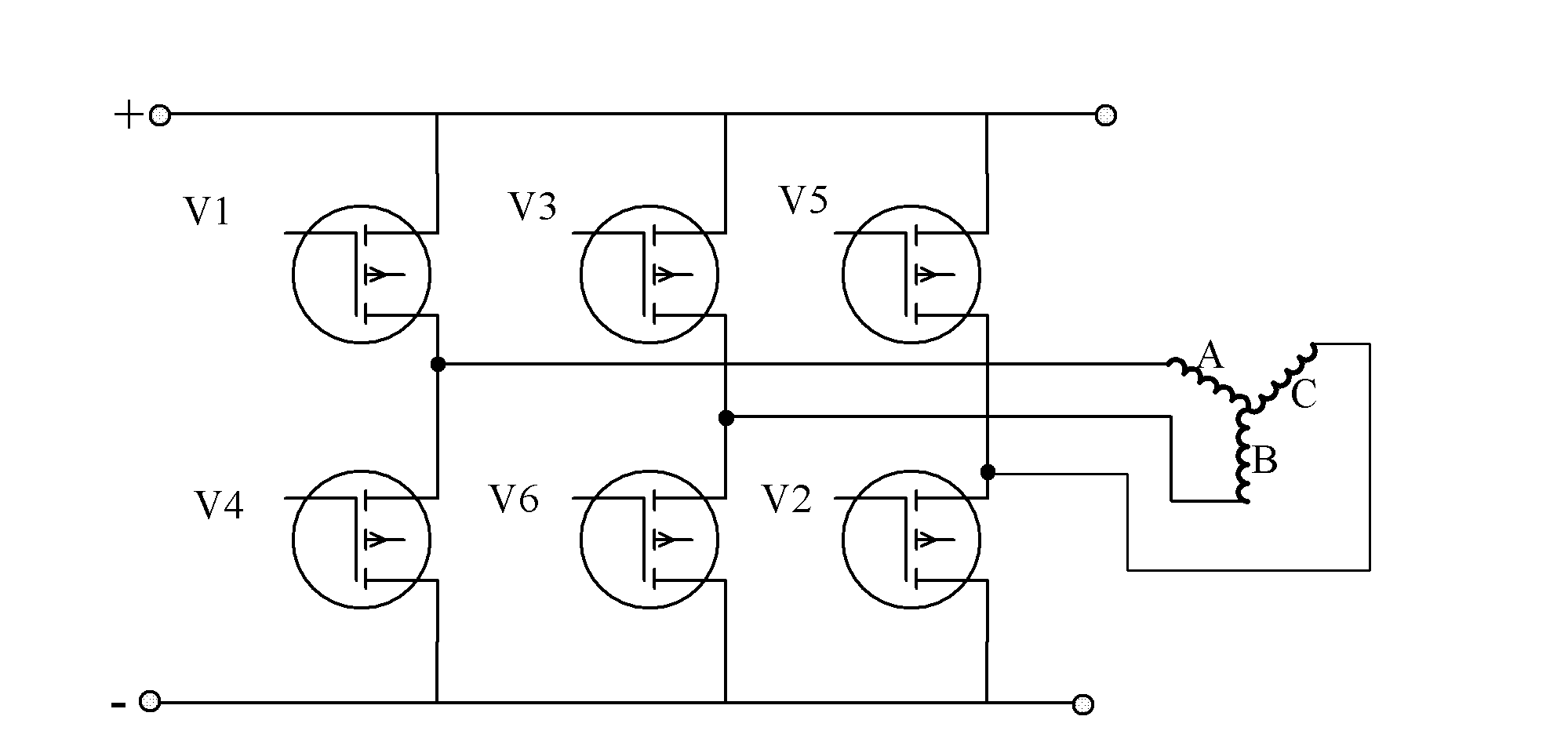

[0052] Such as image 3 The shown dual-axis counter-rotating permanent magnet brushless DC motor drive control system consists of DSP, CPLD, IPM, position detection module, voltage and current detection module, voltage conversion module, and communication module.

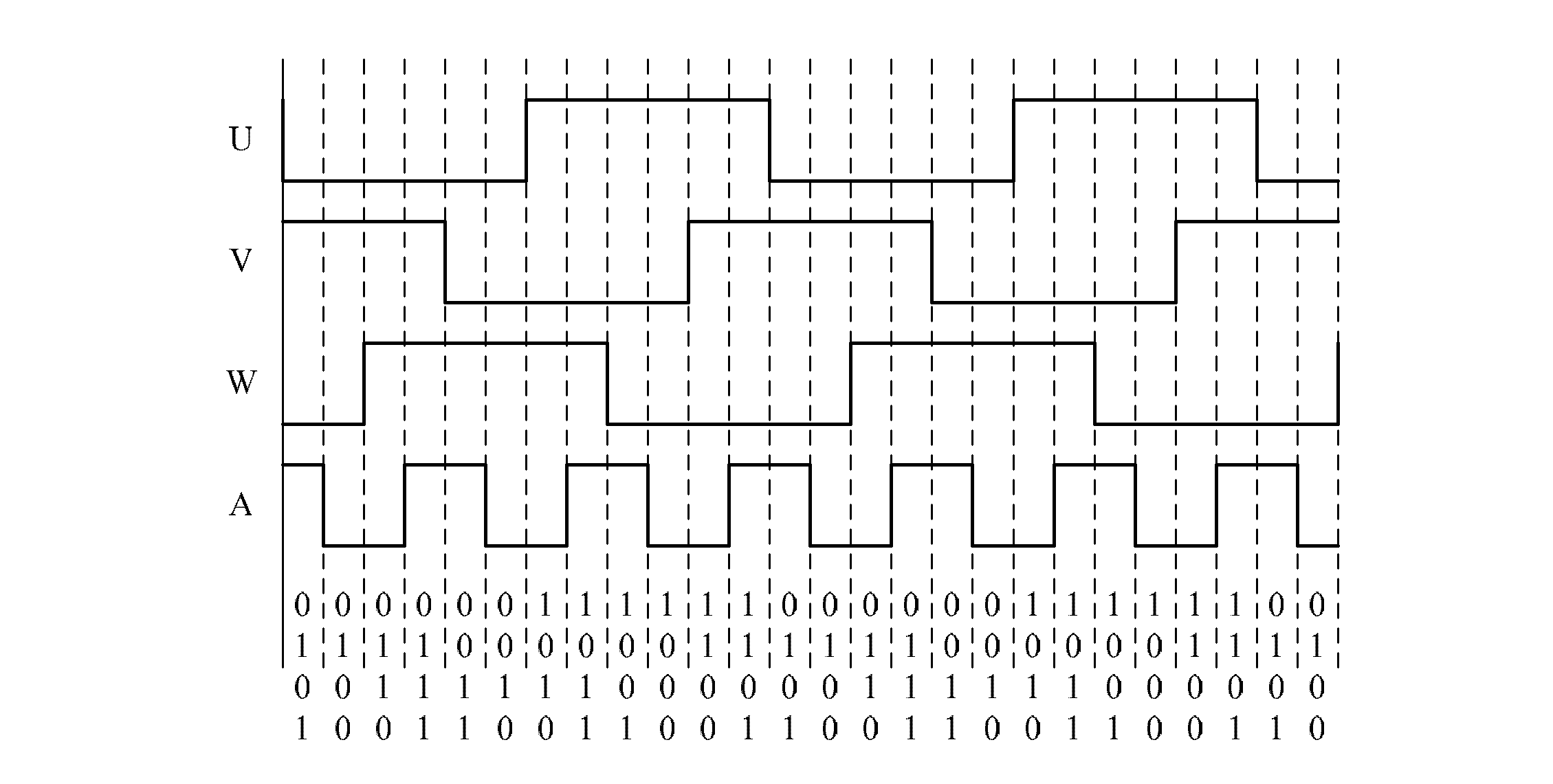

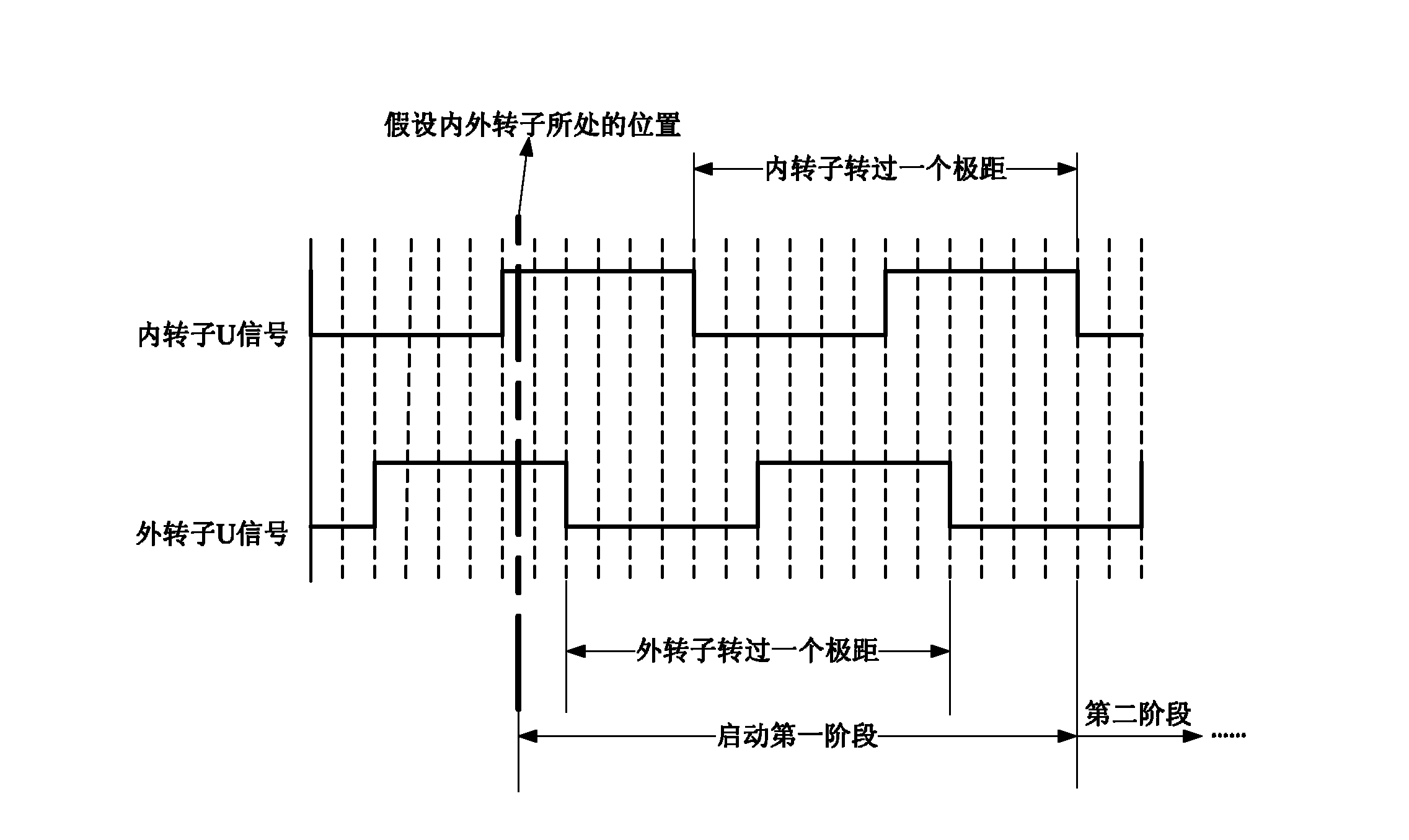

[0053] Formulate the first stage commutation control table

[0054] Step 1. According to the position signals of the inner rotor U, V, W, A, compile the inner rotor state code D, 0≤D≤11, D∈N;

[0055] Step 2. Compile the external rotor position code Z according to the external rotor U, V, W, A position signals, 0≤Z≤11, Z∈N;

[0056] Step 3. Superimpose the angle intervals of the inner and outer rotors, that is, θ=θ 1 +θ 1 , if θ≥360°, let θ=θ-360°;

[0057] a. IF 0°≤θ<60°C=0;

[0058] b. IF 60°≤θ<120°C=1;

[0059] c. IF 120°≤θ<180°C=2;

[0060] d. IF 180°≤θ<240°C=3;

[0061] e. IF 240°≤θ<300°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com