Shielded type printed circuit board

A technology for printed circuit boards and shielding films, which is applied to printed circuits, printed circuit components, circuit devices, etc., can solve the problems of increased area of shielded printed circuit boards and limited design freedom, to maintain the shielding effect and improve design Degree of freedom, reliable equipotential maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

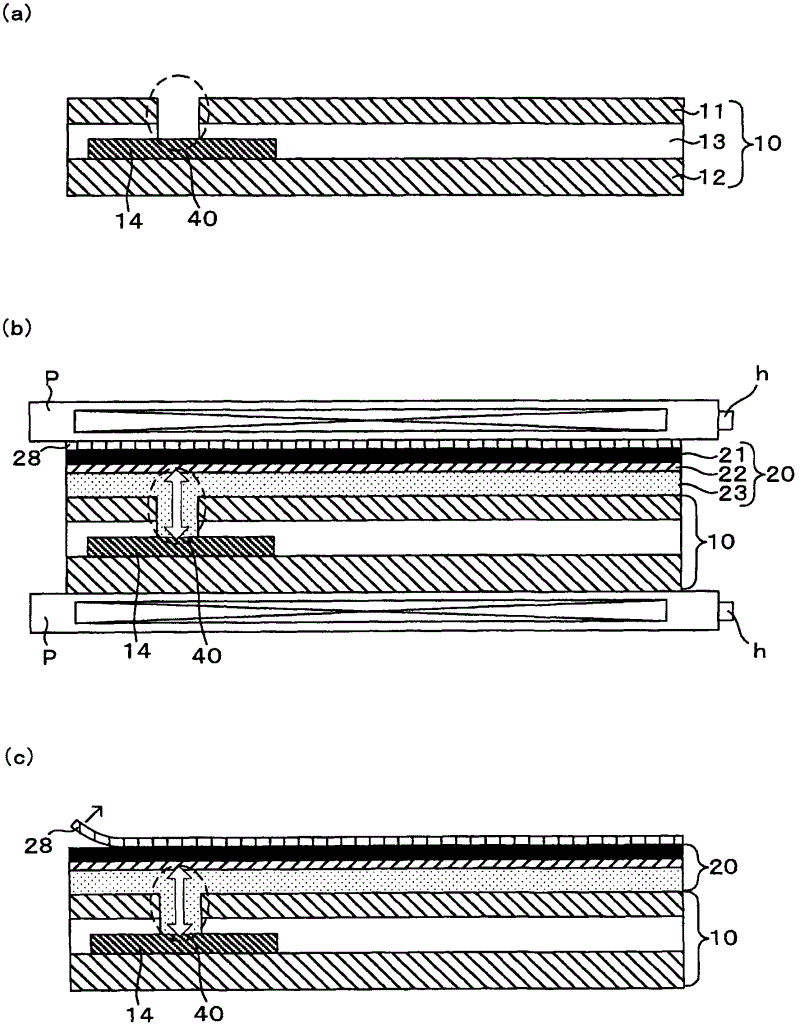

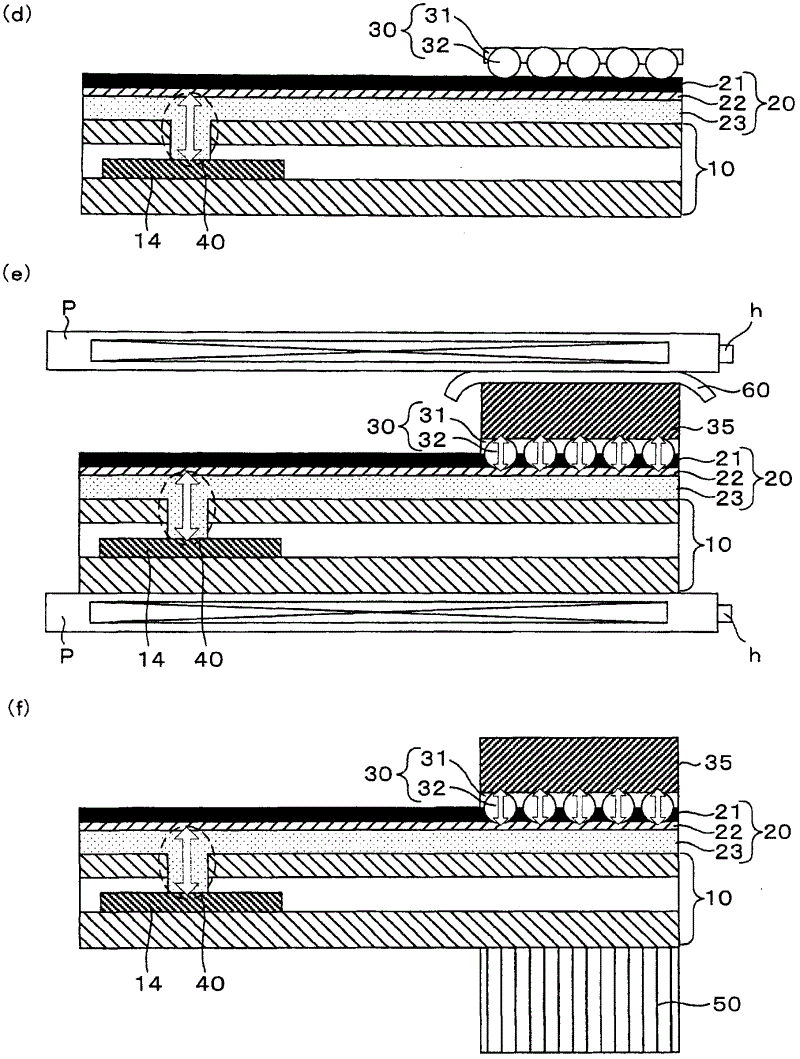

[0036] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0037] (Overall structure of shielded printed circuit board 1)

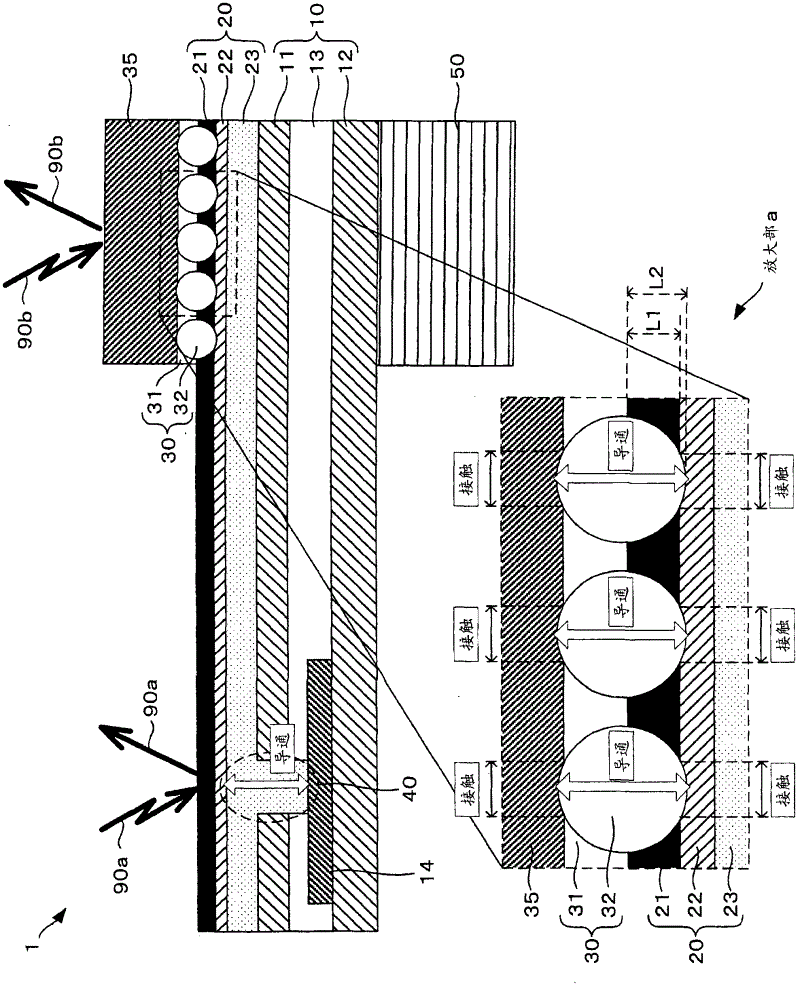

[0038] First, use figure 1 The shield printed wiring board 1 of this embodiment will be described. Such as figure 1 As shown, the shielded printed circuit board 1 includes a printed circuit board 10 , a shielded film 20 and a reinforcing member 35 . Furthermore, an electronic component 50 is connected to a mounting portion provided on the lower surface of the printed circuit board 10 . In addition, the shielding film 20 is provided on the printed circuit board 10 and covers a part or the whole of an area opposite to a mounting portion where the electronic component 50 is connected. Thereby, noises such as electromagnetic waves 90b radiated from the outside to the mounting portion of the electronic component 50 are shielded by the shielding film 20 .

[0039] Furthermore, the reinforcing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com