Fuel injection valve

A technology of fuel injection valve and fuel, which is applied in the direction of fuel injection devices, charging systems, engine components, etc., and can solve problems such as valve needle deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

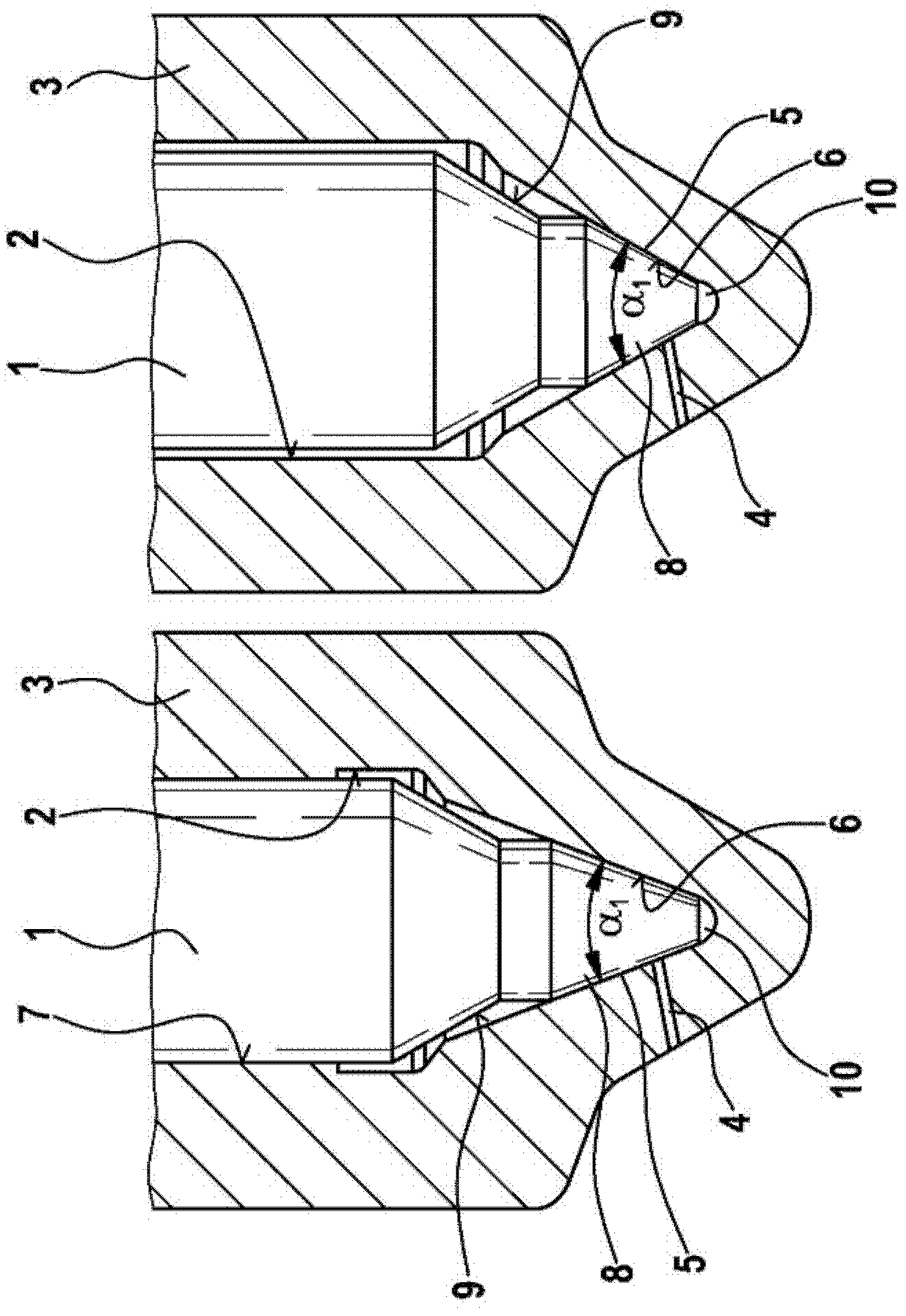

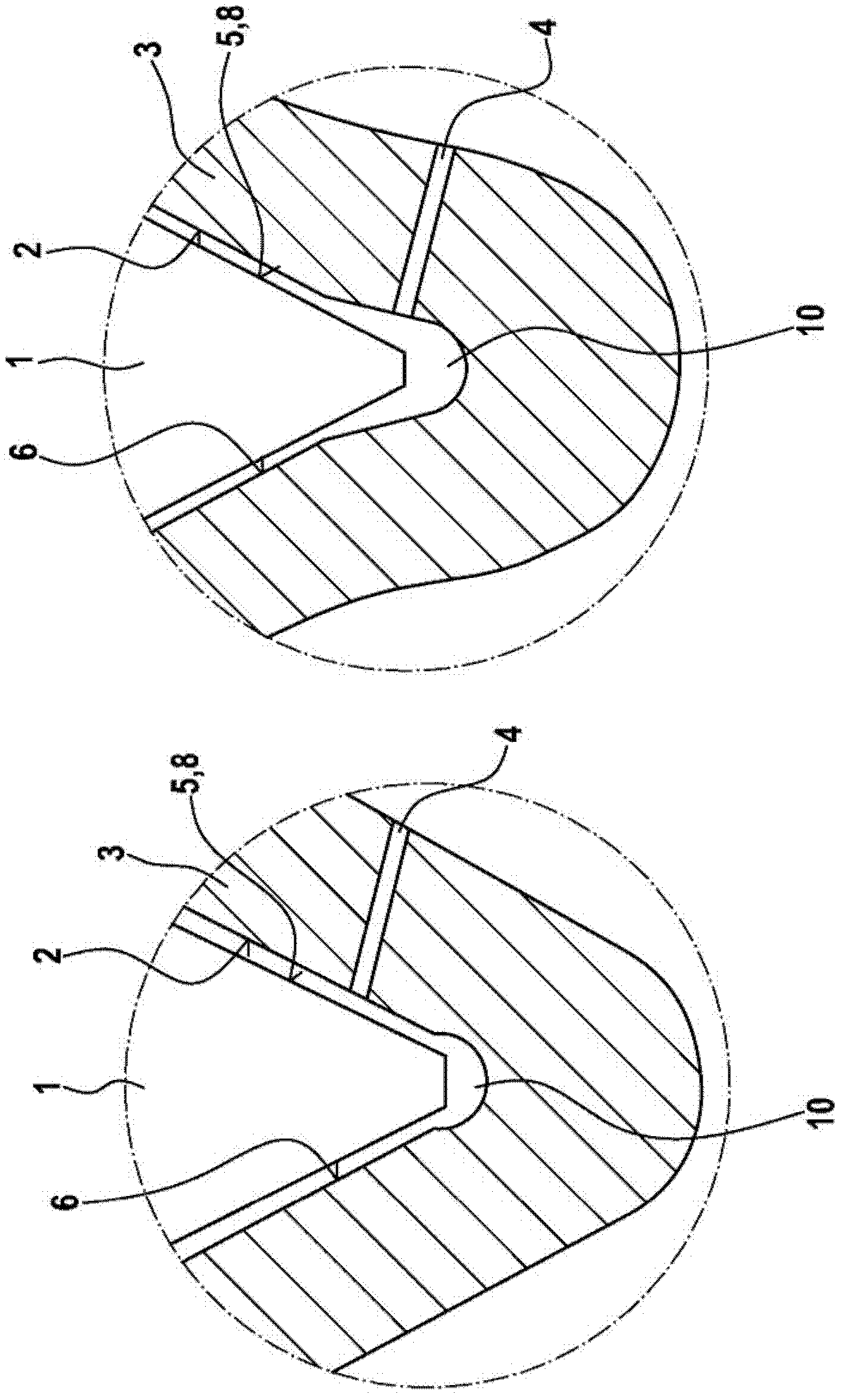

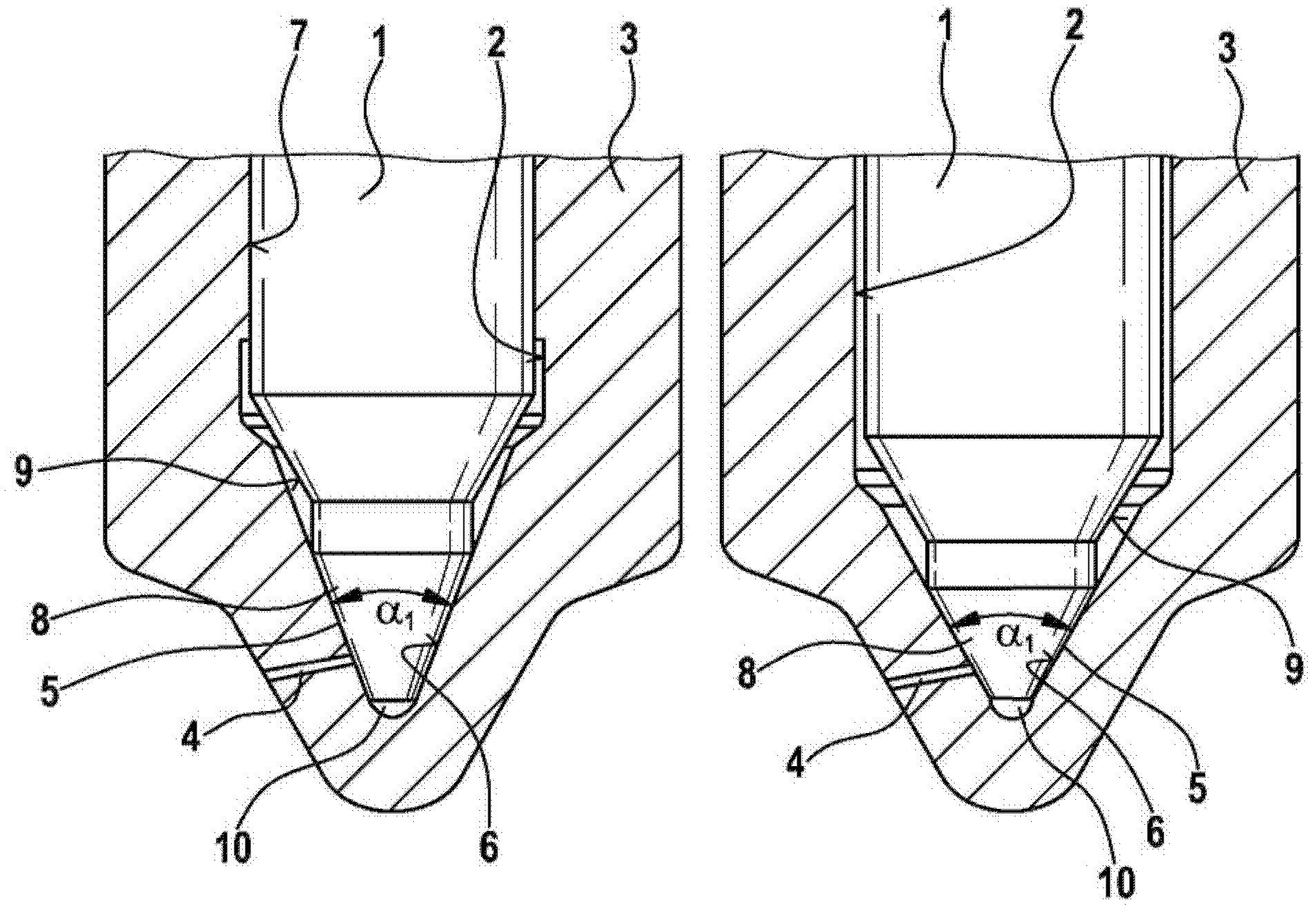

[0018] figure 1 For comparison, a nozzle structure according to the invention is shown on the left and a known nozzle structure is shown on the right. The two nozzle structures comprise a nozzle needle 1 which is guided reciprocatingly in a central bore 2 of a nozzle body 3 . For this purpose, the nozzle structure according to the invention has a guide point 7 close to the sealing surface, which has a reduced diameter. At least one spray opening 4 is released or closed by the reciprocating movement of the nozzle needle 1 . The two nozzles are configured as matching hole nozzles, ie at least one spray hole 4 opens into the central bore 2 at a sealing surface 6 formed within the central bore 2 . The sealing surfaces 6 each have a conical course which substantially corresponds to the conically extending sub-region 8 of the nozzle needle 1 and forms the sealing point 5 . The cylindrical subsection and then the conical subsection adjoin the conical subsection 8 of the nozzle nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com