Elevator car and counterweight automatic balancing energy-saving device with auxiliary counterweight, and control system

An energy-saving device and control system technology, which is applied to elevators, transportation and packaging, and elevators in buildings, and can solve problems such as energy waste in elevator traction drives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

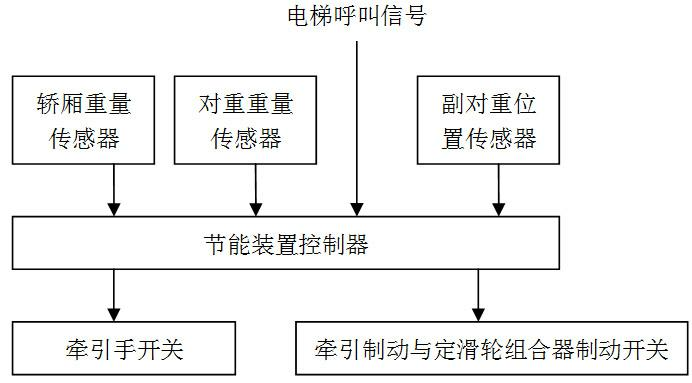

[0029] 1. Introduction to the functions of the main components of the device of the present invention

[0030] The auxiliary counterweight 11 is used to balance the weight difference between the 4 cars and the 3 counterweights on both sides of the 1 traction sheave. From Figure 7 It can be seen that a set of energy-saving devices has four sets of secondary counterweights, which are installed on the hoistway walls on both sides of the car, with two sets on each side. The installation guide rail of the car has divided the elevator shaft wall into front and rear areas, so each side has a group of front and rear areas. Looking down from the top of the hoistway, the auxiliary counterweights arranged diagonally can be used in pairs to ensure the balance of forces on all sides of the car, or they can be used individually as needed.

[0031] The docking or unloading of the auxiliary counterweight during elevator operation is realized by the 12 traction hands in the energy-saving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com