Energy-saving and consumption-reducing method for air supply system of metallurgy blast furnace

An air supply system and blast furnace technology, applied in the field of metallurgical blast furnaces, can solve problems such as high energy consumption and complex equipment, and achieve the effects of reducing emissions, reducing thermal pollution, and saving operating management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

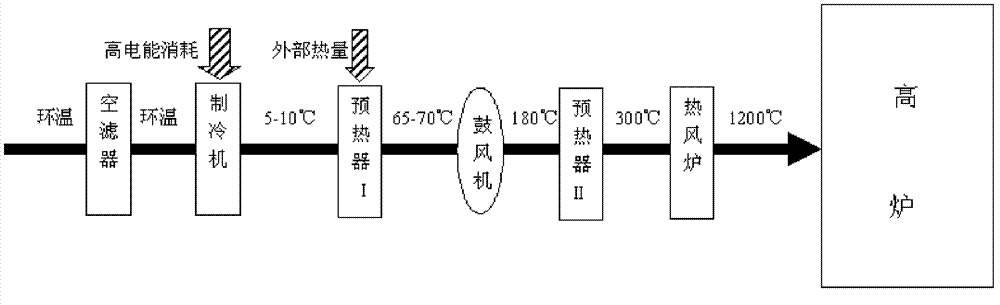

Problems solved by technology

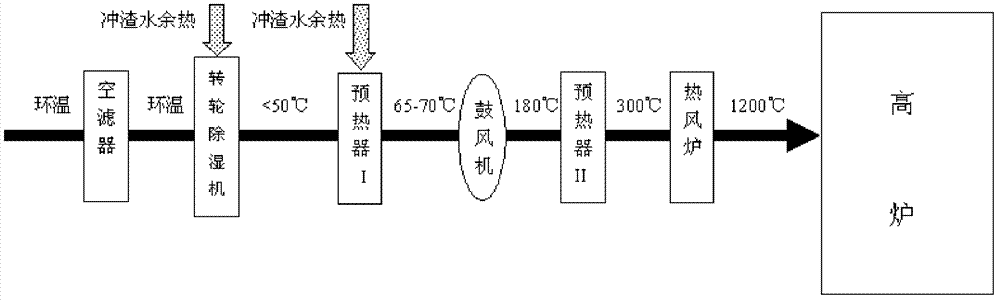

Method used

Image

Examples

specific example and

[0029] Basic situation: one 500 cubic meter blast furnace, slag flushing water temperature 85-90 ℃, 160 tons / hour;

[0030] Preheating air volume: 75,000 cubic meters to 90,000 cubic meters per hour.

[0031] Blast furnace slag flushing water is recycled industrial cooling water, and the hot water for slag removal needs to be cooled to 60°C through the cooling water tower before being recycled, resulting in a large amount of waste heat being discharged into the atmosphere. Calculated according to the temperature drop and flow rate of the slag washing water, the waste heat discharged into the atmosphere is (calculated at 90°C):

[0032] Q=160×1000×(90-60)=4.8 million kcal / hour (about 5600kWh)

[0033] Due to the limitation of the temperature of the slag washing water, the air waste heat temperature can reach up to 80°C. For the calculation of the air waste heat of a 500 cubic blast furnace (calculated at 90,000 cubic meters per hour), the required air preheating heat is calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com