Anti-loosing threaded fastener

A threaded fastener, anti-loosening technology, applied in the direction of threaded fasteners, locking fasteners, screws, etc., can solve the problems of difficult installation and disassembly, and achieve simple structure, easy repeated installation and disassembly, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

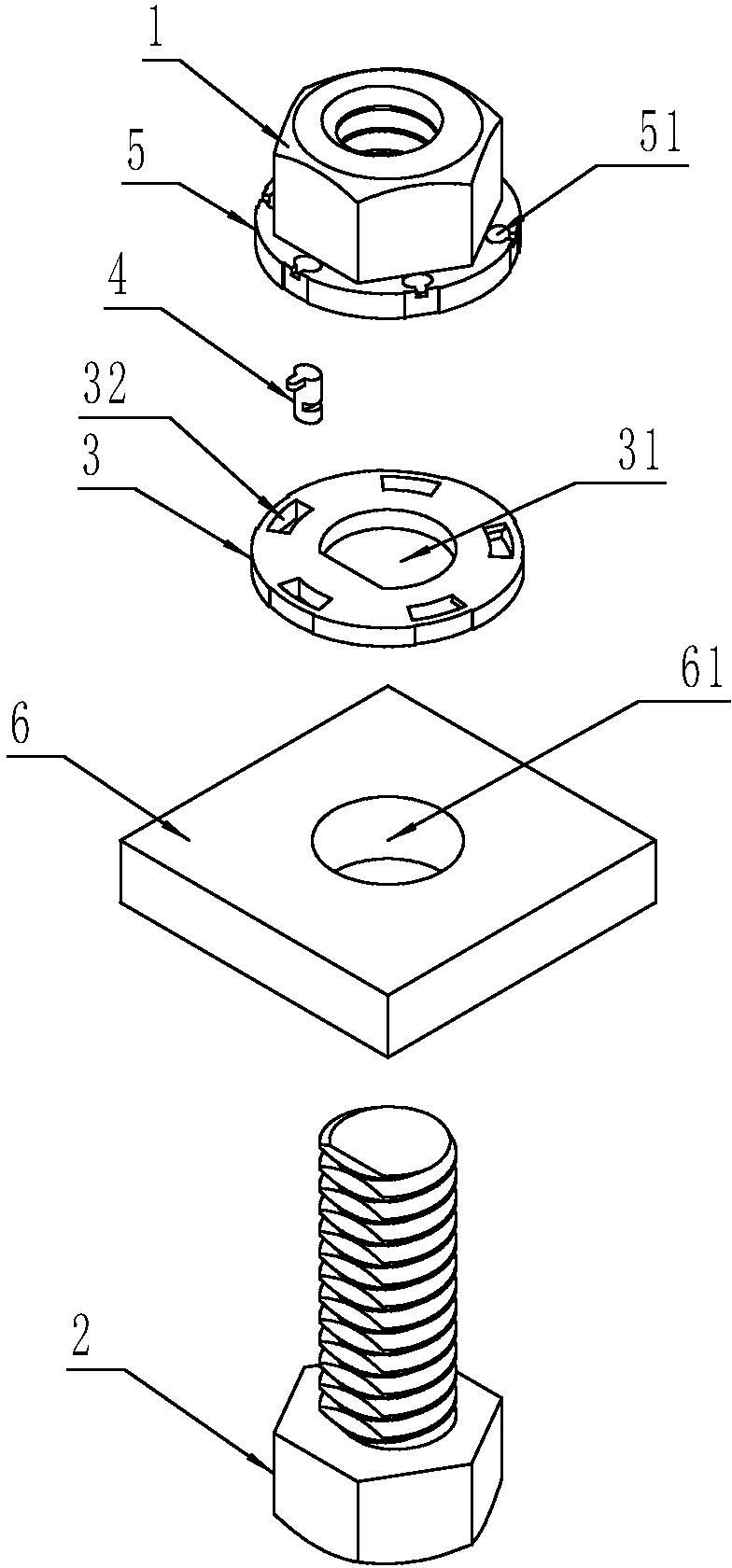

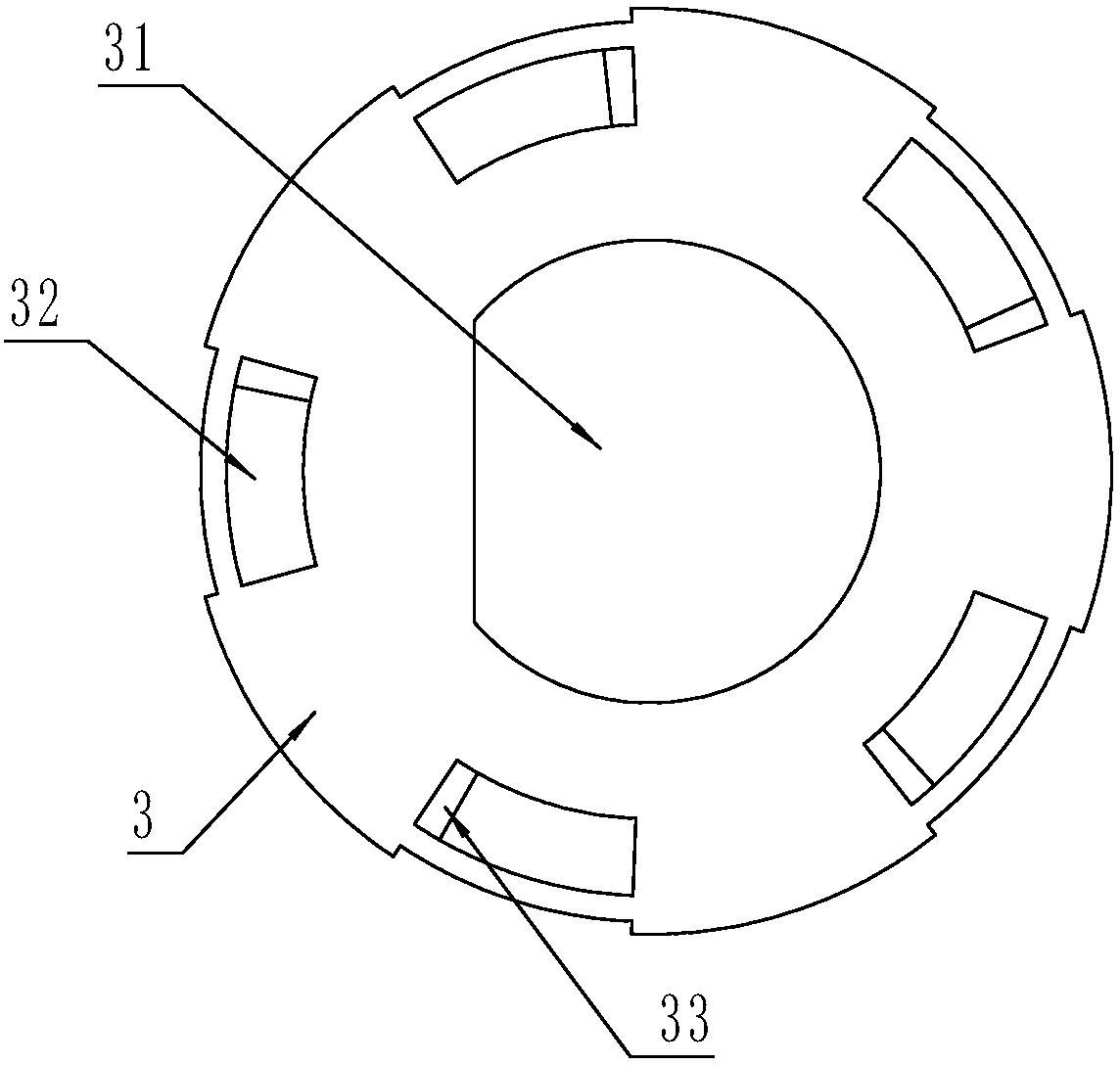

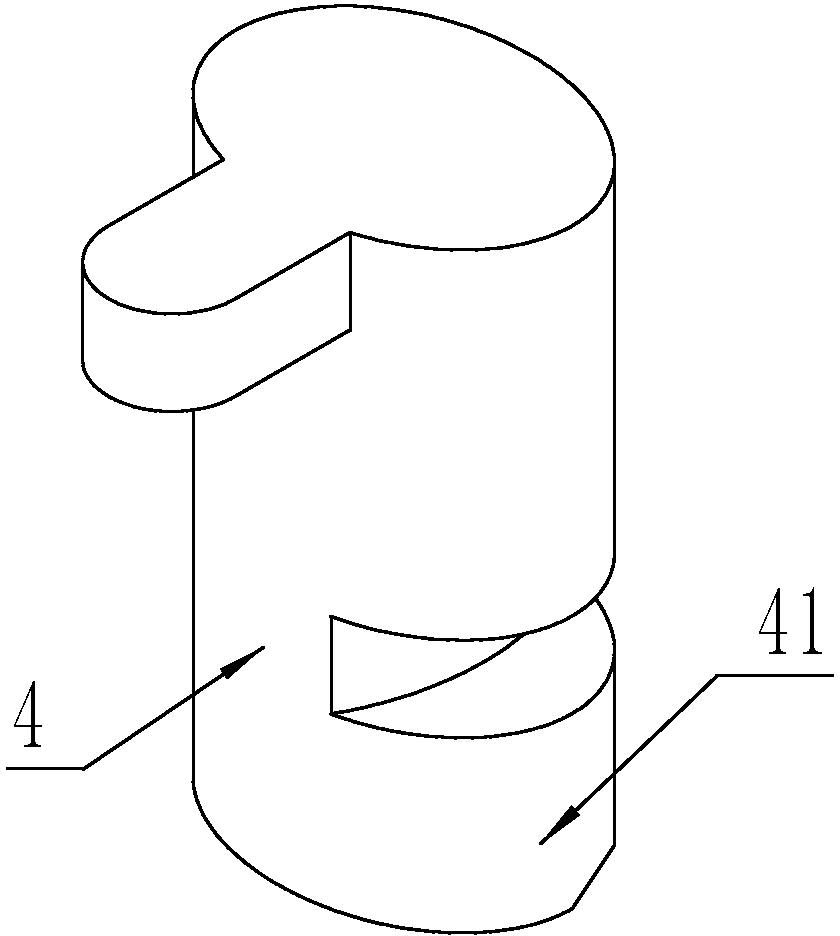

[0030] Such as figure 1 As shown, the anti-loosening threaded fastener includes a nut 1, a bolt 2, a washer 3 and a pin 4, the center of the washer 3 is provided with a central hole 31 through which the bolt 2 can pass, and the nut 1 is provided with a protruding ring 5, The central hole 31 of the gasket 3 is a round hole, and the structure of the bolt 2 corresponds to the round hole, so that the bolt 2 and the gasket 3 are locked and connected to each other in the circumferential direction. The protruding ring 5 is provided with a Several convex ring holes 51, several gasket holes 32 are arranged on the gasket 3 along the ring direction, when the nut 1 is in a tightened state on the bolt 2, at least one convex ring hole 51 completely overlaps with the gasket hole 32, and the pin 4 Set in the completely overlapping collar hole 51 and gasket hole 32, as figure 2 As shown, the gasket hole 32 is provided with a protrusion 33, such as image 3 As shown, the pin 4 is provided wi...

Embodiment 2

[0033] Such as Figure 4 As shown, the anti-loosening threaded fastener includes a nut 1, a bolt 2, a gasket 3 and a pin 4, and the center of the gasket 3 is provided with a central hole 31 for the bolt 2 to pass through, as Figure 5 As shown, the nut 1 is provided with a convex ring 5, the gasket 3 is provided with a gasket convex tooth 34 on the contact surface of the workpiece 6, and the bolt convex tooth 21 is provided on the contact surface of the bolt 2 and the workpiece 6. The gasket The protruding teeth 34 and the protruding teeth 21 of the bolts can also be replaced by a protruding tooth plate with protruding teeth on both sides, so as to realize the mutual locking connection between the bolt 2 and the gasket 3 along the ring direction, and the upper edge of the protruding ring 5 Several convex ring holes 51 are arranged in the direction, and several gasket holes 32 are arranged on the gasket 3 along the circumferential direction. When the nut 1 is in a tightened sta...

Embodiment 3

[0036] Such as Figure 7As shown, the anti-loosening threaded fastener includes a nut, a bolt 2, a washer 3 and a pin 4, the center of the washer 3 is provided with a central hole 31 for the bolt 2 to pass through, the bolt 2 is provided with a protruding ring 5, and the washer Between the sheet 3 and the first workpiece 6, a convex tooth sheet 8 with convex teeth on both sides is provided, and the nut and the second workpiece 7 are integrally structured. In this embodiment, the second workpiece 7 is provided with a threaded hole 71. In this way, the nut and the washer 3 are locked and connected to each other in the circumferential direction. The protruding ring 5 is provided with several protruding ring holes 51 in the circumferential direction, and the washer 3 is provided with several spacer holes 32 in the circumferential direction. The bolt 2 When the second workpiece 7 is in a tightened state, at least one collar hole 51 is completely overlapped with the gasket hole 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com