Modular projection light module of a motor vehicle headlamp

A technology of projecting light and light source, applied in the field of projecting light modules, which can solve the problems of high development cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

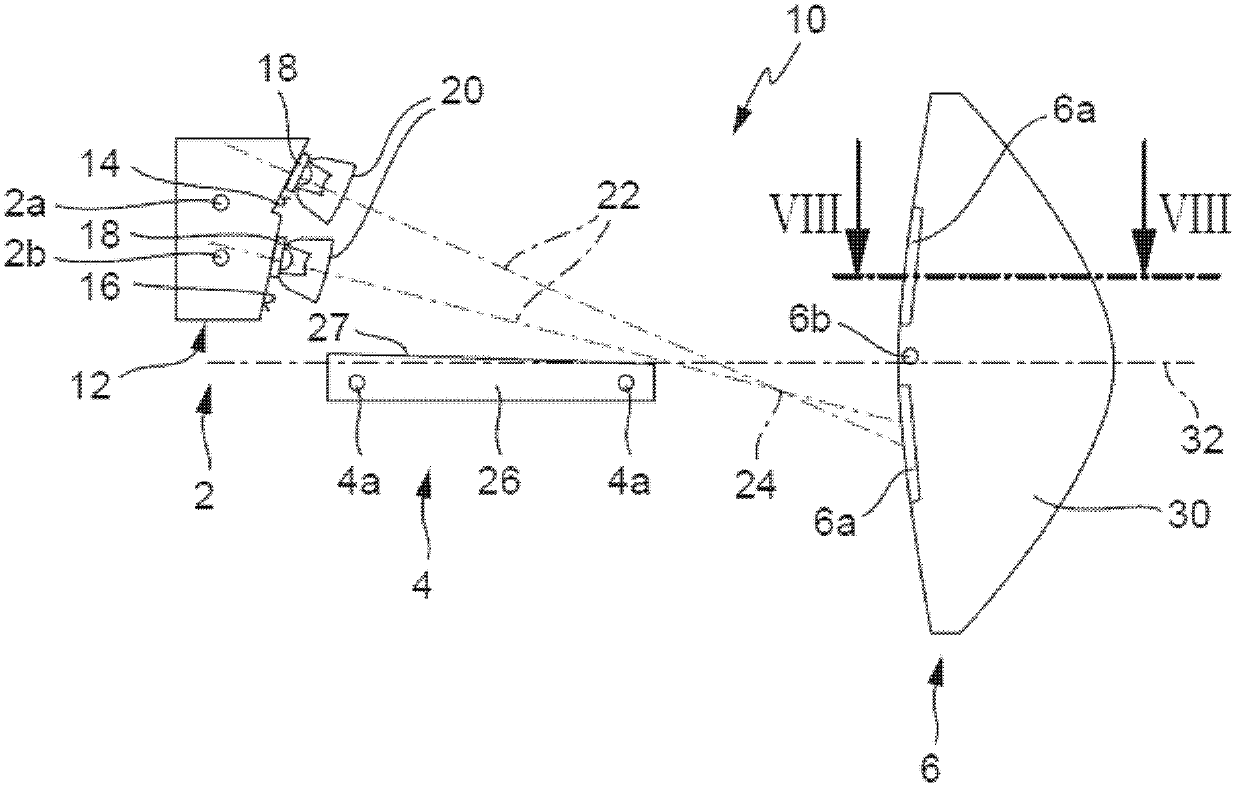

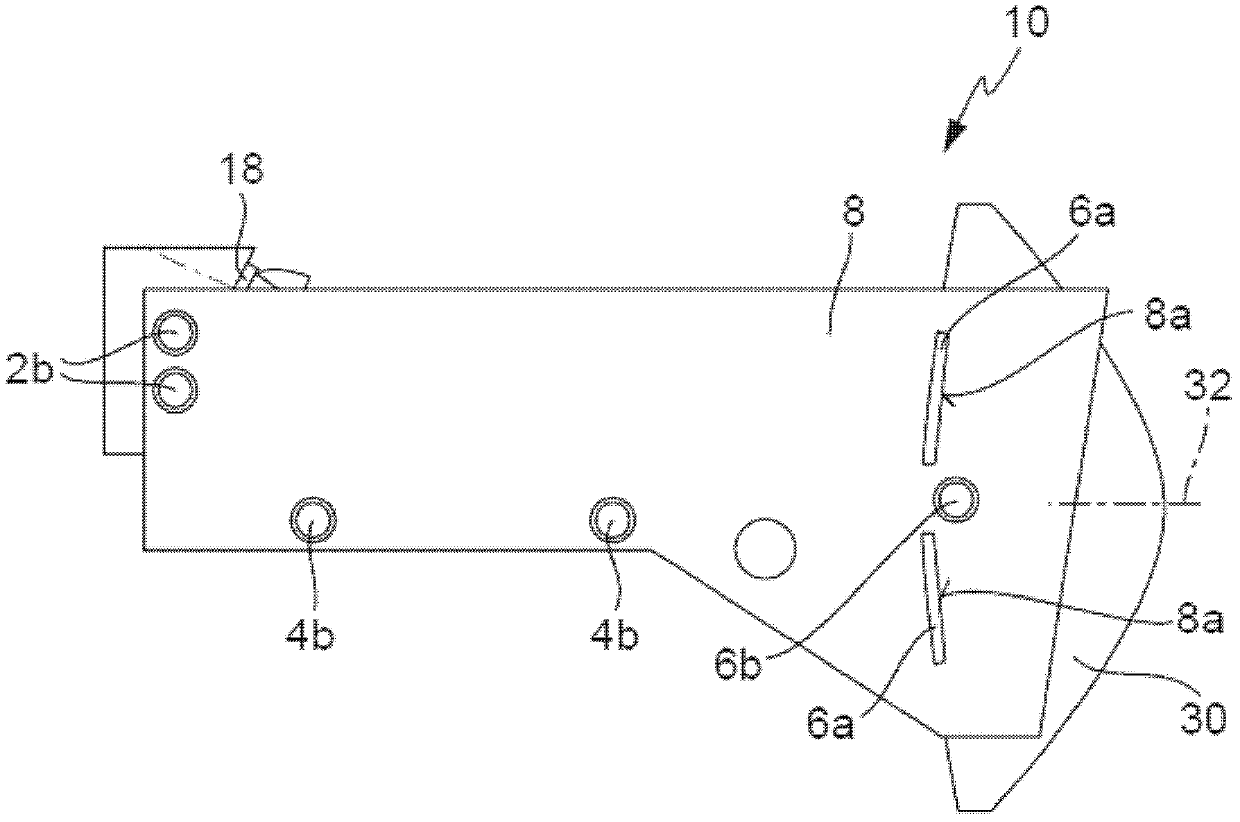

[0038] In this case, the same reference numerals designate identical or at least functionally identical elements in each of the figures.

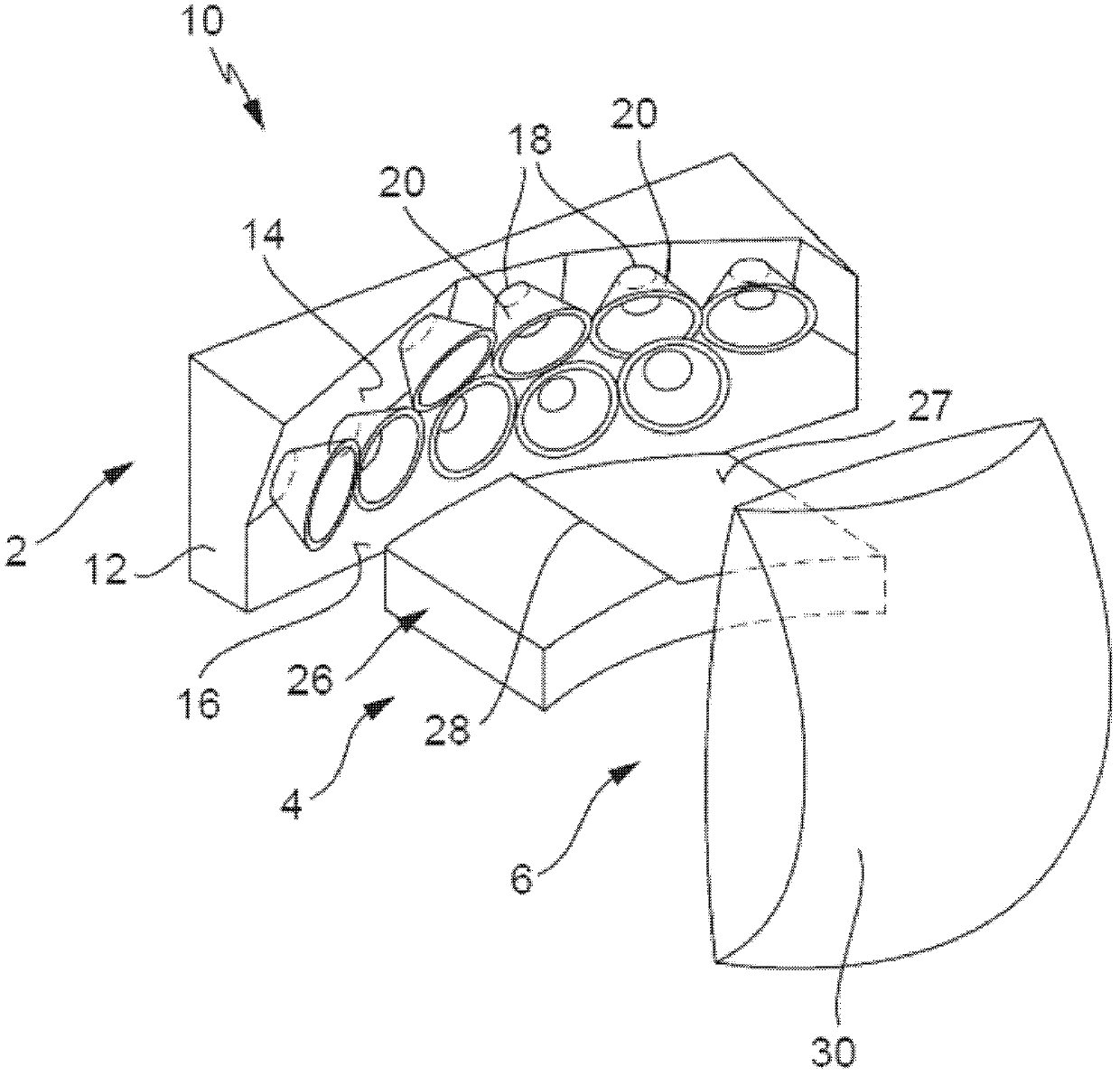

[0039] Generally, people divide the projection light module including semiconductor light sources into four functional groups from the perspective of manufacturing technology and design: these functional groups involve the light source unit, the visor unit, the lens holding unit and the lens unit. figure 1 with 2 The structures of the light source unit, the visor unit, and the lens unit are shown. image 3 These three functional groups are shown, in addition to the lens holding unit.

[0040] figure 1 The structures of the light source unit 2 , the visor unit 4 and the lens unit 6 of the light projection module 10 are shown in detail.

[0041] The light source unit 2 has a heat sink 12 made of a material having a high thermal conductivity, such as aluminum, magnesium, copper, or an alloy containing such metals. In one configuration, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com