A laser etching process for saw blade cutting structure

A technology of laser etching and sawing, which is applied in the direction of metal sawing equipment, laser welding equipment, sawing machine knives, etc., can solve the problems of inability to cut quickly, corrosion resistance, thick blade, etc., and achieve free and flexible blade thickness. Good sharpness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

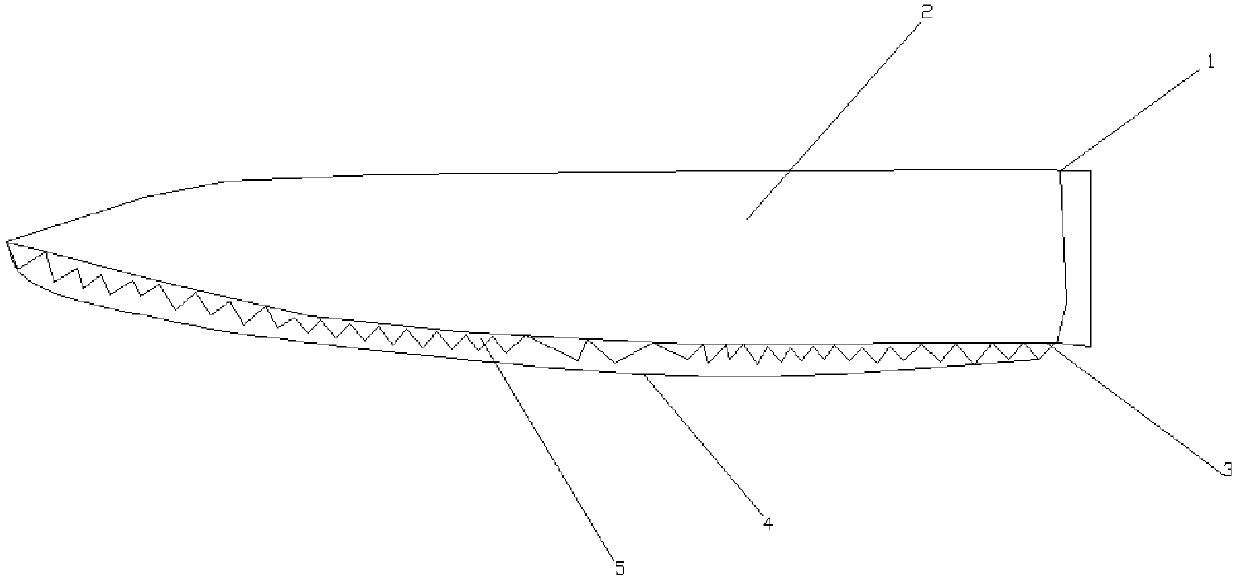

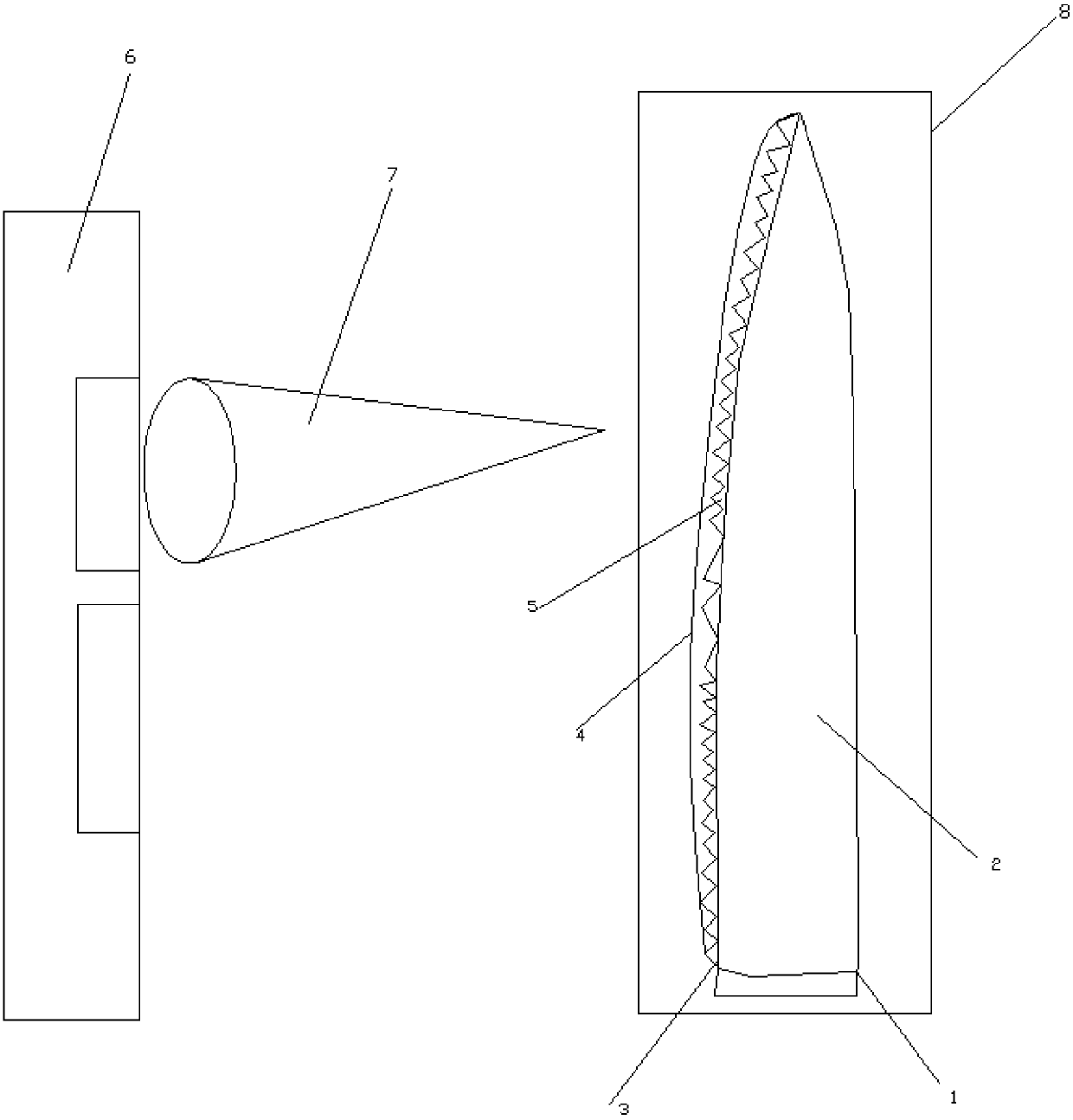

[0055] The user uses a saw blade cutting structure and its laser etching process of the present invention, the laser 6 etches the saw blade body 1, the laser 6 can etch a free-form blade, and the laser beam 7 traces the laser beam 7 during the laser etching process The way, routing sequence, etching thickness, and discharge current are different. Therefore, the sharpness and toughness and hardness of the saw blade body 1 are different accordingly. The shape, profile or size of the etched object 6 is etched, and the laser etching processing method includes the following steps: 1) Generate laser etching data according to the shape, size or profile of the saw blade body 1, and the laser etching data includes finishing data and Rough processing data; 2) Use the laser 6 to perform profiling etching on the saw blade body 1 according to the laser etching data to generate the shape of the tool; 3) After profiling, perform rough etching; 4) Perform rough machining on the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com