Electric connector for flat conductor and method for assembling electric connector with flat conductor

An electrical connector, flat technology, applied in the field of electrical connectors, can solve the problems of complex structure of the limit device, unfavorable production efficiency, and many processes, so as to achieve convenient and fast assembly, improve production efficiency and product quality, and be easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

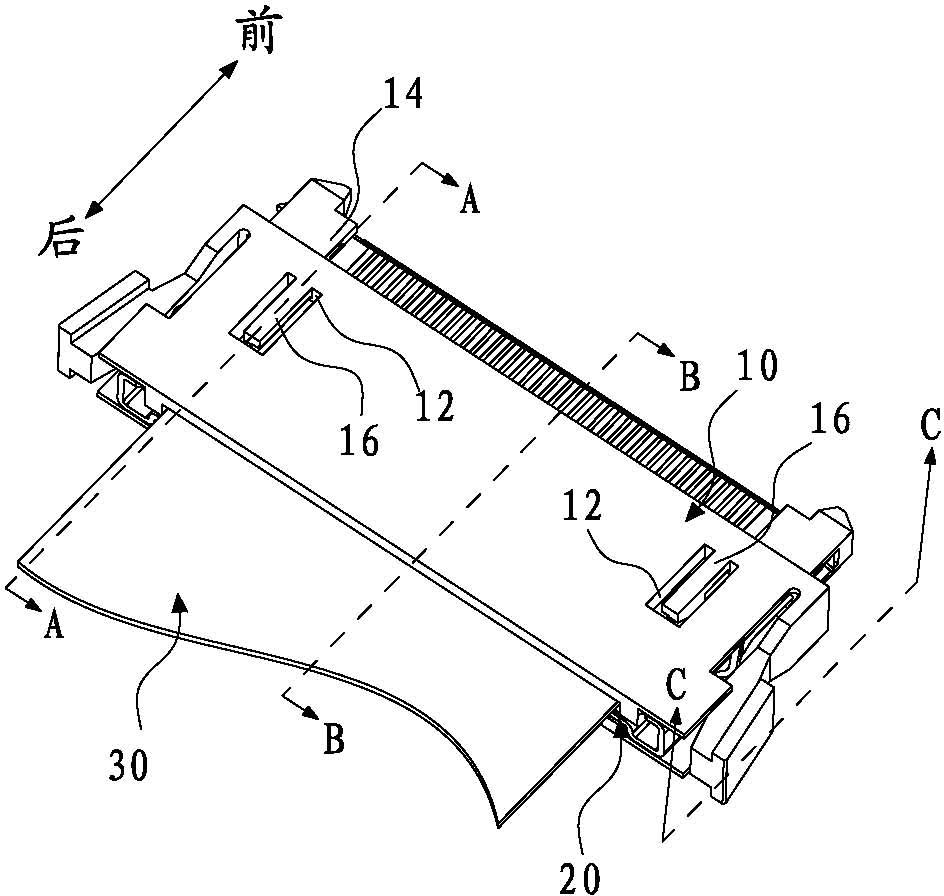

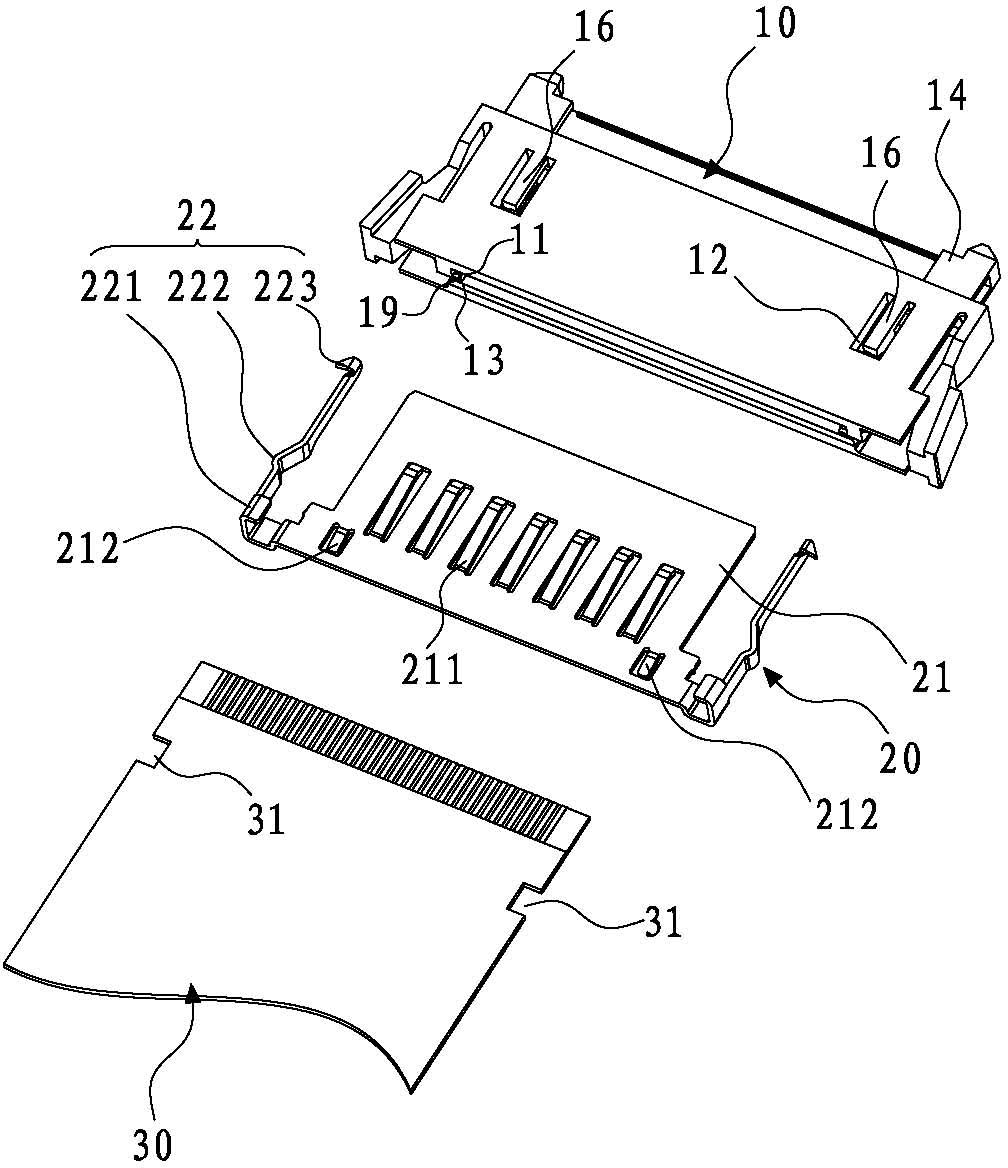

[0054] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the first embodiment of the present invention, including an insulating body 10 , a shielding shell 20 and a flat conductor 30 , and the flat conductor 30 is provided with two gaps 31 .

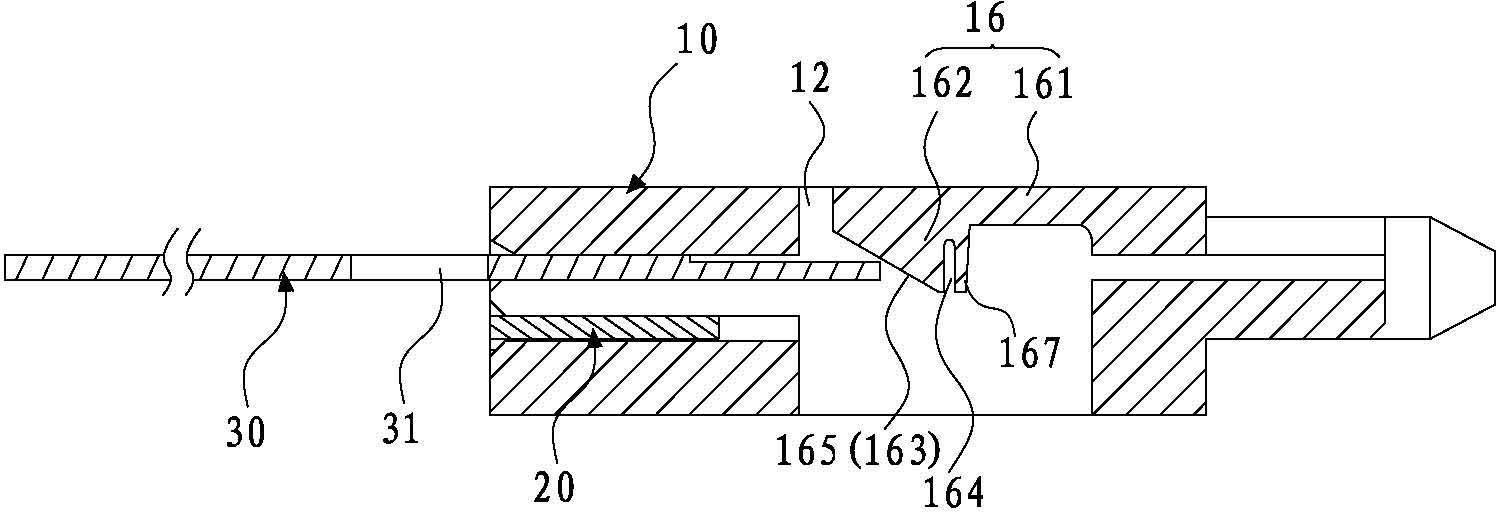

[0055] Such as figure 2 and Figure 8 As shown, the insulating body 10 has an integrated structure, and one side of the insulating body 10 is formed with an opening guide groove 11 for introducing a flat conductor 30 with a connecting portion at the front end, and the opposite side is formed with a The fitting part for connector fitting, the fitting part is provided with a fitting opening communicating with the above-mentioned guide groove 11, and the connection part on the flat conductor 30 is introduced from the open guide groove 11 and positioned in the above-mentioned fitting part to connect with the other party device contact; the rear entrance of the guide groove 11 is formed with an introduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com