Greenhouse interpenetrating production method and special double-body greenhouse structure

A technology of shed structure and main shed, applied in the field of greenhouses, can solve the problems of waste, high cost, production reduction, etc., and achieve the effect of increasing land utilization, improving yield and quality, and making up for market vacancies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

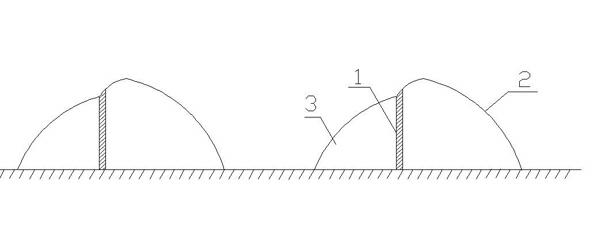

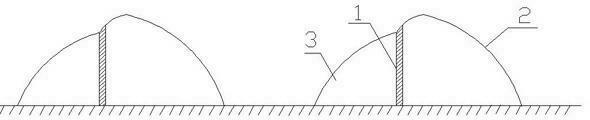

[0018] The double-body greenhouse structure includes insulation wall 1, main shed 2 and auxiliary shed 3. The main shed is set on the side of the insulation wall facing the sun, and the auxiliary shed is set on the side of the insulation wall facing away from the sun. The main shed and the auxiliary shed share the same insulation wall.

[0019] Both the main shed and the auxiliary shed are shed-like structures with high and low ends. The high end of the main shed is set on the sunny side of the insulation wall, and the low end of the main shed is set on the ground in front of the insulation wall; the high end of the auxiliary shed is set on the The insulation wall faces away from the sun, and the lower end of the shed is set on the ground behind the insulation wall.

[0020] The length of the paid shed is the same as that of the main shed, and its width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com