Hand-held cutting and milling machine

A hand-held, cutting and milling technology, which is applied in the direction of milling machines, milling machine equipment, metal processing equipment, etc., can solve the problems of cutting, large depth, large volume, etc., and achieve the effect of improving work efficiency, increasing success rate, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

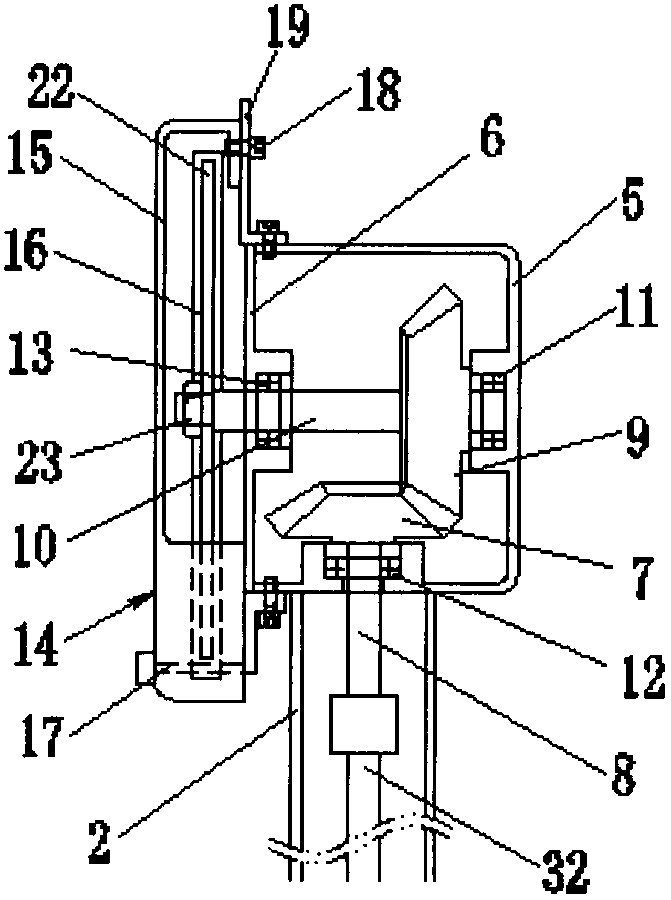

[0016] like figure 2 As shown, the gear box cover 6 is fixed on the gear box 5 with screws, the driven bevel gear 9 is horizontally installed in the gear box 5, one end of the driven gear shaft 10 is installed in the gear box sleeve 11, and the other end passes through Gear case cover is contained in case cover axle sleeve 13 lis. The driving bevel gear 7 is longitudinally installed in the gearbox 5 and meshed with the driven bevel gear 9; The outer diameter of the gear box 5 is less than 50 mm.

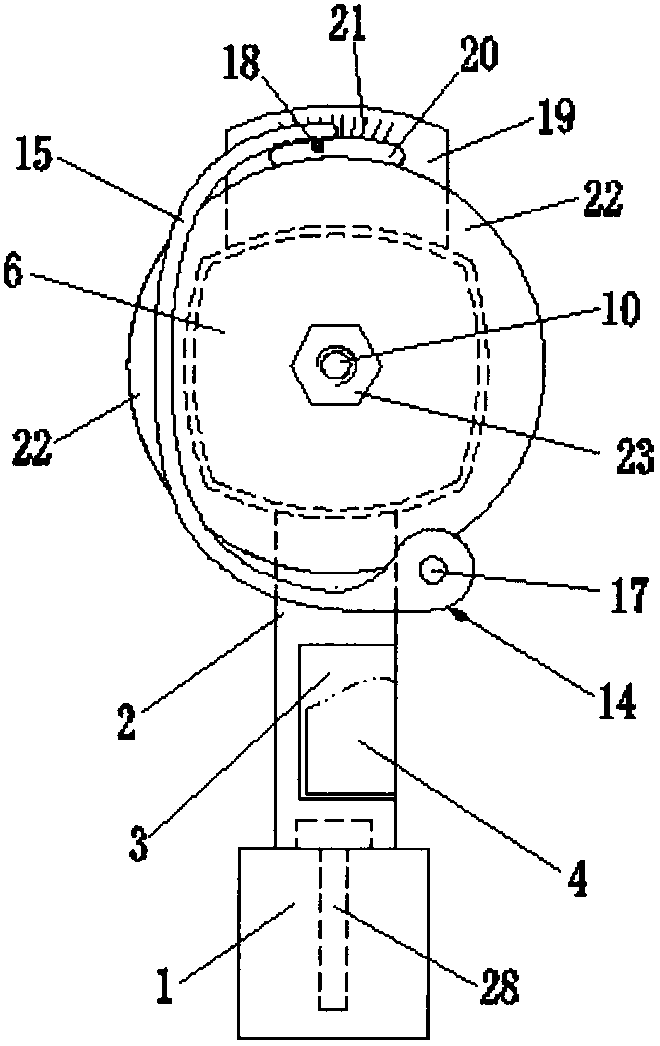

[0017] like figure 1 Shown, depth gauge 19 is fixed on the top of gear box 5. A positioning groove 20 is horizontally opened in the middle of the depth ruler 19 , and a depth line 21 is engraved on the upper edge of the positioning groove 20 .

[0018] like figure 1 , 2 As shown, the milling positioner 14 is a C-shaped object. One end of the cutting and milling positioner 14 is provided with a rotating shaft 17, and the extension of the rotating shaft 17 is fixed on the botto...

example 2

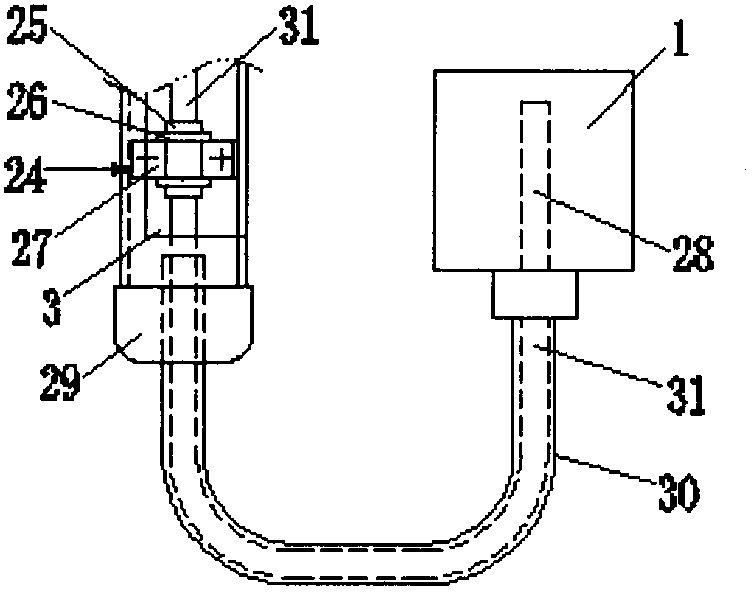

[0022] like figure 1 As shown, a flexible shaft locator installation opening 3 is opened in the middle of the shaft shank 2, and a shaft shank cover 4 matching it is also provided on the flexible shaft locator installation opening 3.

[0023] like image 3 As shown, the flexible shaft positioner 24 is made up of a bearing 27, a slot bolt 25, and a clamping wire 26. The slot bolt 25 passes through the inner hole of the bearing 27, and the clamping wire 26 fixes the slot bolt 25 and the bearing 27 together.

[0024] still as image 3 As shown, one end of the axle shaft 2 is fixedly connected with the bottom of the gear box 5, and the other end is covered with an axle handle head cover 29. The flexible shaft locator 24 is installed in the lumen of the shaft shank 2 from the flexible shaft locator mounting port 3 on the shaft shank 2 . The outer diameter of the bearing 27 on the flexible shaft positioner 24 is consistent with the inner diameter of the axle shaft 2 .

[0025] a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com