Opener

A hole opener and ring-shaped technology, which is used in laser printers, photocopiers, toner cartridge bins, and waste toner bins, can solve problems that affect work efficiency, are difficult to remove, and burn the surface of the toner bin with a soldering iron. Improve work efficiency and heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

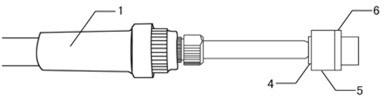

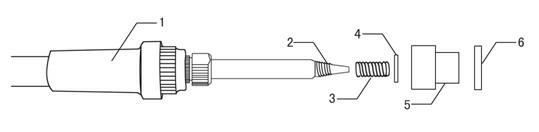

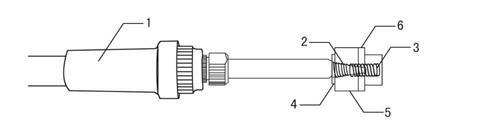

[0018] Such as figure 1 , figure 2 , image 3 , first pass the soldering iron tip (2) through the spacer (4), then connect the spring (3) to the soldering iron tip (2); pass the spring (3) and the soldering iron tip (2) through the ring opener (5) Bottom threaded hole and tightened to fix; Figure 5 , install the asbestos heat insulation sheet (6) to the step of the annular heat insulation sheet (5).

[0019] In specific use, the electric soldering iron (1) is energized and heated to conduct to the soldering iron tip (2), and the soldering iron tip (2) is connected to the annular hole opener (5) through threads, and the heat is conducted to the annular hole opener (5) . Such as Figure 4 , Figure 5 , when the annular hole opener (5) reaches the set temperature, hold the electric soldering iron (1) and place the annular hole opener (5) on the designated position of the injection molded parts of the toner cartridge bin and waste toner bin, press down slightly, and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com