Cocoon screening device

A screening device and silkworm cocoon technology, applied in the field of silkworm cocoon processing, can solve problems such as low efficiency, high labor intensity of workers, and poor quality of cocoons, and achieve the effects of simple and convenient operation, reduced labor intensity of workers, and accurate screening results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the drawings and embodiments.

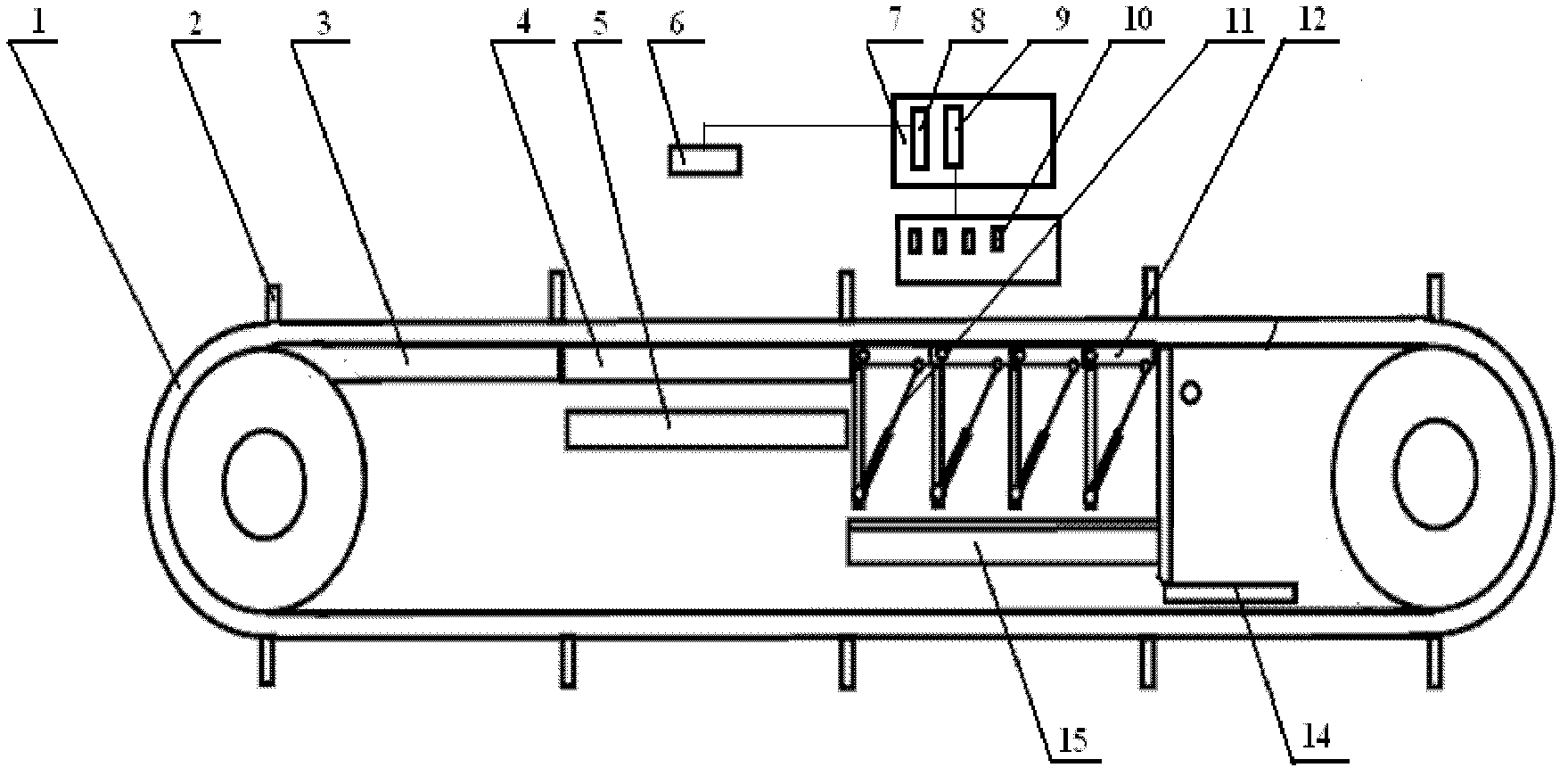

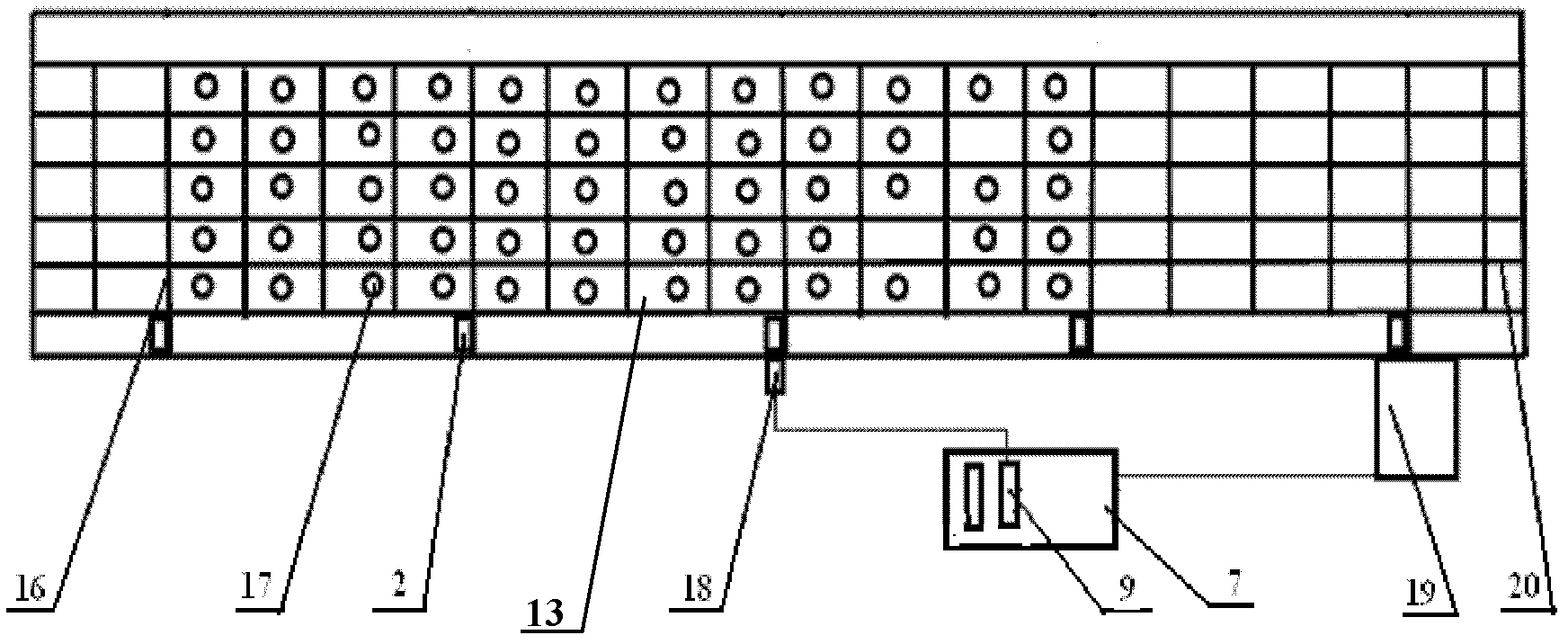

[0011] Such as figure 1 , figure 2 As shown, a cocoon screening device includes a conveyor belt 1, a push plate 16 and a chain plate 20 are installed in the middle of the conveyor belt 1, the chain plate 20 is along the conveying direction, the push plate 16 is perpendicular to the conveying direction, the chain plate 20 and the push plate The plates 16 form a plurality of grids 13 spaced apart from each other. A plurality of iron sheets 2 are uniformly arranged on one side of the conveyor belt 1. The number of the grids 13 between two adjacent iron sheets 2 is the same. Below the conveyor belt 1 A discharge board 3, a perspective board 4, a door panel 12, and a cocoon pond 14 are arranged in sequence. A fluorescent light source 5 is installed below the perspective board 4, and a CCD camera 6 is installed above the perspective board 4. The CCD camera 6 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com