Combined seepage interception wall structure capable of running through complicated strong permeable bed and construction method

A construction method and strong permeable technology, which can be used in infrastructure engineering, water conservancy engineering, sheet pile walls, etc., can solve the problems of poor wall quality, high cost, and high risk of leakage damage, and can solve construction difficulties and construction safety. , to solve the effect of poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

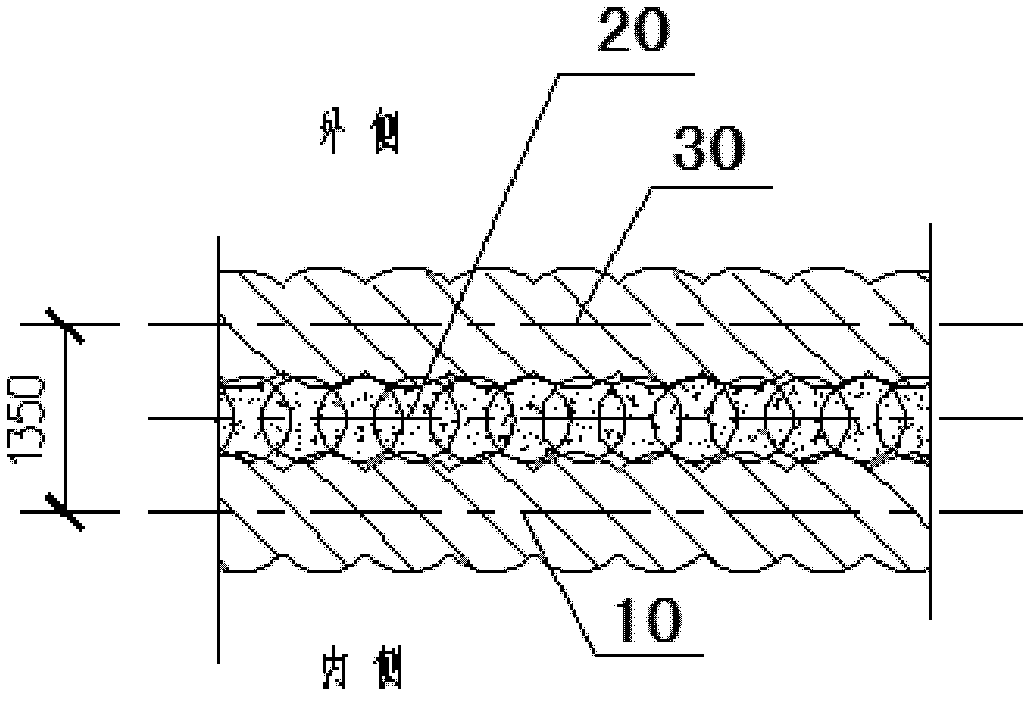

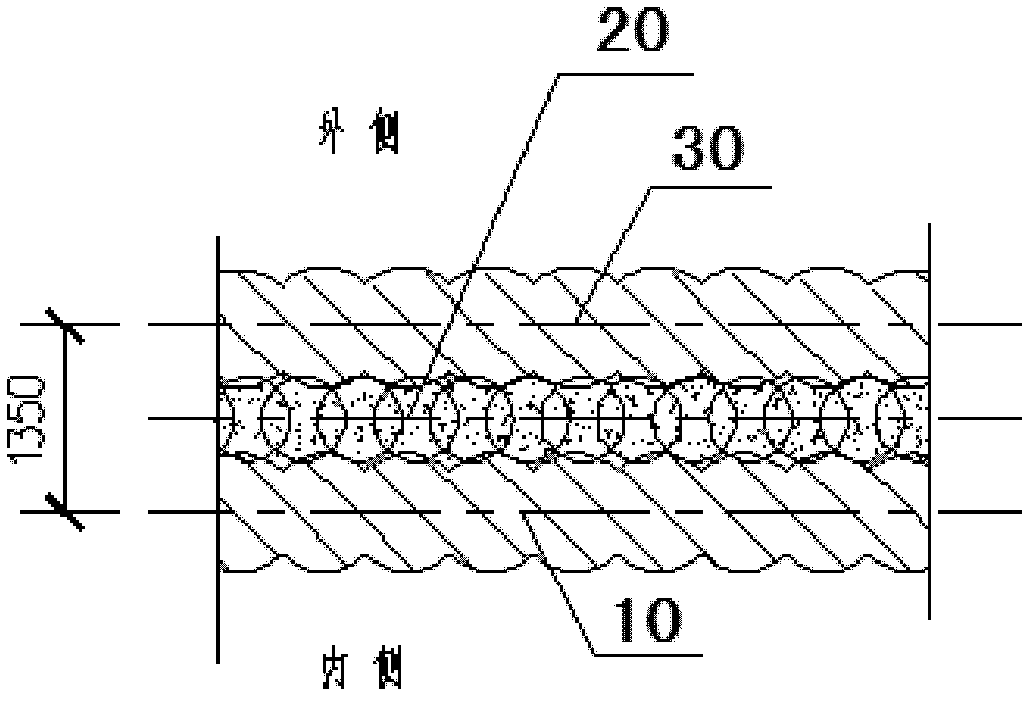

[0017] see figure 1 , the combined cut-off wall structure passing through the complex strong permeable layer shown in the figure is composed of an inner wall 10, an intermediate wall 20 and an outer wall 30 in sequence from the outside to the inside, and the inner wall 10 and the outer wall 30 are composed of three Axial stirring piles are used to form a wall, and the middle wall 30 is formed by high-pressure rotary jetting piles; the thickness of the middle wall is 0.5m.

[0018] The construction method of the combined cut-off wall structure passing through the complex strong permeable layer is composed of the following steps:

[0019] 1) Exterior wall construction

[0020] The external wall is made of three-axis mixing piles, and the three-axis mixing piles are laid out with φ850-600mm and re-stirred in the permeable interlayer range to ini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com