Vibration shaking sieve used for finished product bin based on sand lime brick production

A technology for finished silos and lime-sand bricks, which is applied in the direction of filter screen, solid separation, grille, etc., which can solve the problems of uneven pressure, wear of main engine and mold, and easy lumping and coagulation of materials, so as to avoid unnecessary wear and tear, Improvement of quality and improvement of molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

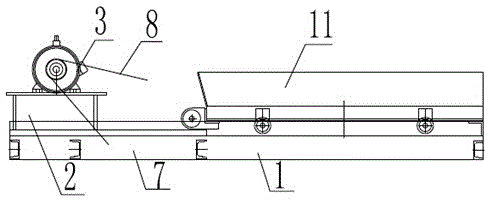

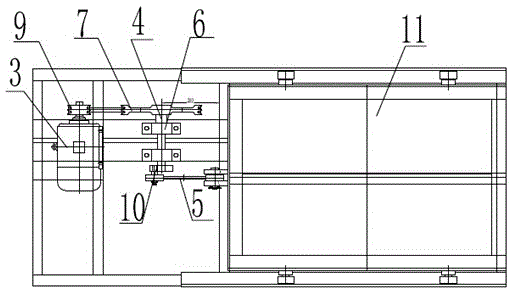

[0012] Such as figure 1 , 2 As shown, the vibrating sieve for the finished product bin for producing lime-sand bricks includes a support part and a drive part, and the support part includes a fixed frame 1 and a motor support 2 at one end of the fixed frame 1; the drive part includes a motor 3, a transmission The shaft 4, the connecting rod 5, and the transmission shaft 4 are fixed on the beam of the fixed frame 1 through two bearing seats 6. One end of the transmission shaft 4 is equipped with a large pulley 7, and is connected with a small pulley 9 on the motor shaft through a belt 8 , the other end of the transmission shaft 4 is equipped with an eccentric wheel 10, the eccentric wheel 10 is connected with the screen body 11 through the connecting rod 5,

[0013] When the motor 2 is working, the small pulley 9 on the output shaft of the motor 2 rotates, and the large pulley 7 at one end of the transmission shaft 4 is driven to rotate synchronously by the belt 8, and the ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com