Self-tangency broaching anchor bolt

An anchor bolt and self-cutting technology, applied in the direction of light impact tools, connecting components, pins, etc., can solve the problems of reduced milling continuity, low milling continuity, and unsatisfactory milling performance of metal materials, etc., to achieve the goal of improving milling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

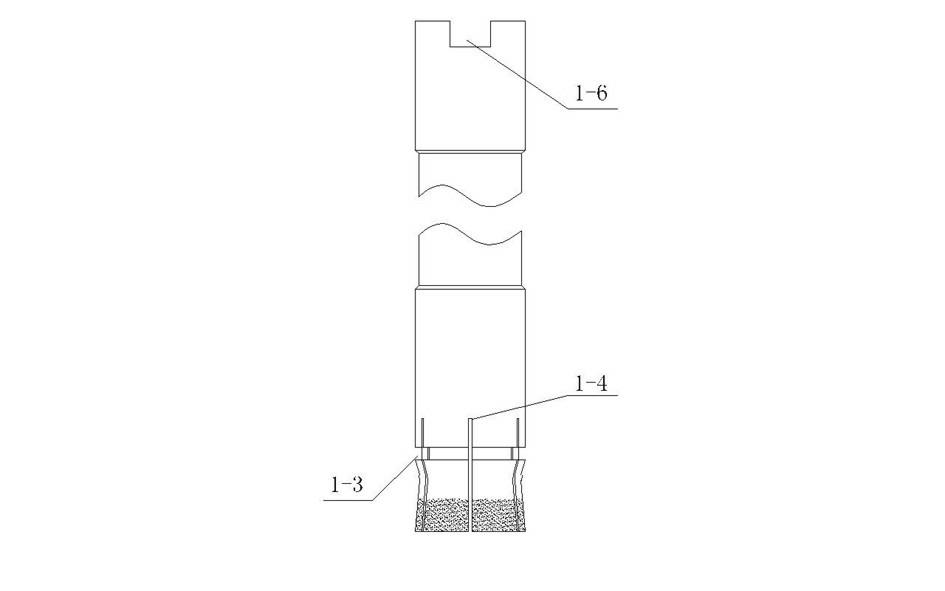

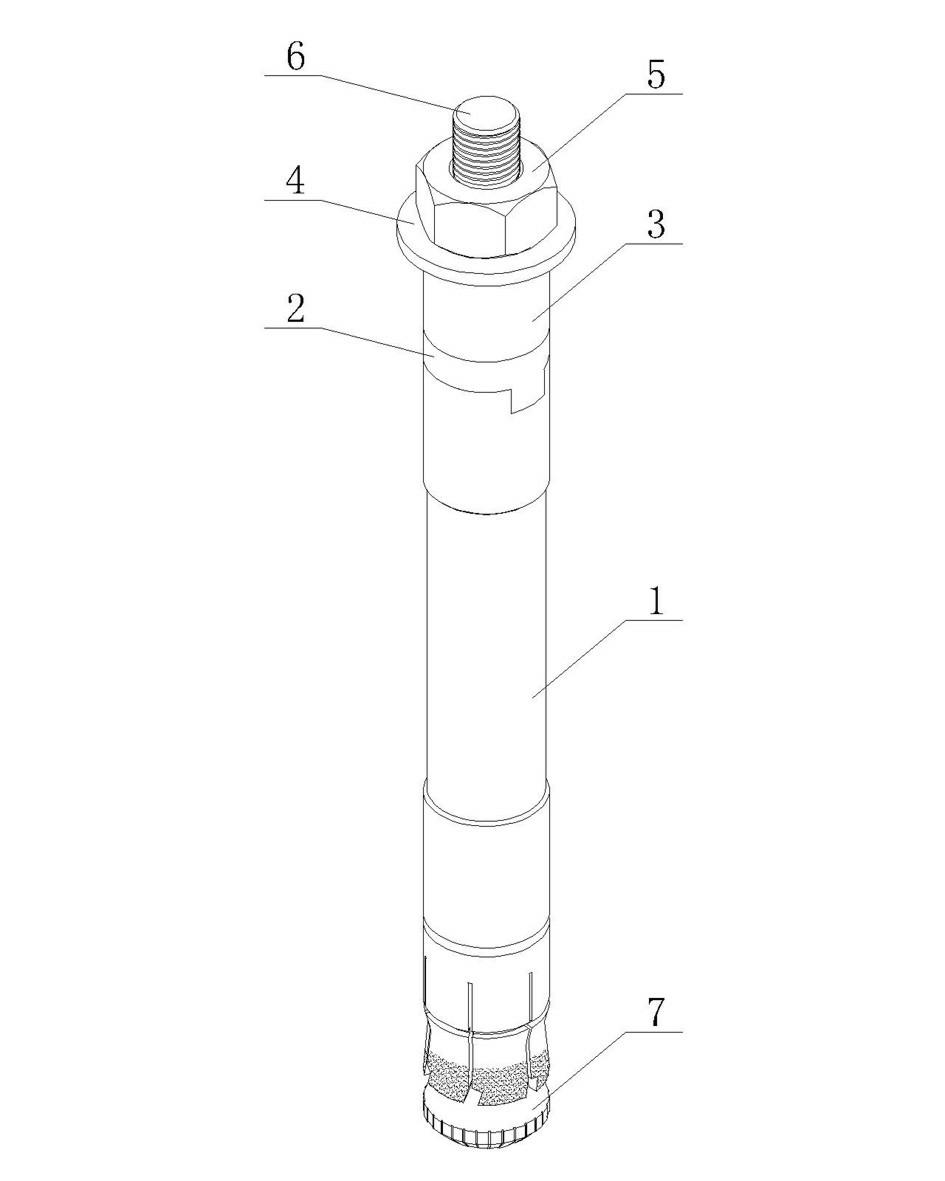

[0051] Such as image 3 , Figure 4 , Figure 5 Shown is one of the designed embodiments of the present invention. In this embodiment, the self-cutting and reaming anchor bolt includes a sleeve 1 with an expansion structure at the lower end, and a slot 1 fitted with an installation tool at the upper end of the sleeve 1. -6, the expansion structure is composed of slits 1-4 to divide the wall of the lower end of the sleeve 1, including several expansion pieces, in this embodiment, 6 expansion pieces are used, and the common 4 pieces, and other appropriate numbers can also be used expansion film. The lower end of the expansion structure is provided with a milling structure, which includes cutter teeth 1-1 uniformly distributed around the axis of the sleeve 1. The structure of the cutter teeth 1-1 can be referred to Figure 5 .

[0052] The side of the cutter tooth 1-1 that rotates toward the sleeve 1 has a milling blade 1-2, the blade 1-2 is located at the lower end of the cr...

Embodiment 2

[0060] Figure 6 Shown is the 2nd kind of embodiment of the present invention, compared with embodiment 1, cutter tooth 1-1 is welded with cemented carbide block at blade 1-2 position, and cemented carbide has hardness high, wear-resisting, strength and toughness Excellent performance, heat resistance, corrosion resistance and a series of excellent properties, it is a common constituent material in milling tools. If the size of the part allows, the cemented carbide block can be fixed by riveting.

Embodiment 3

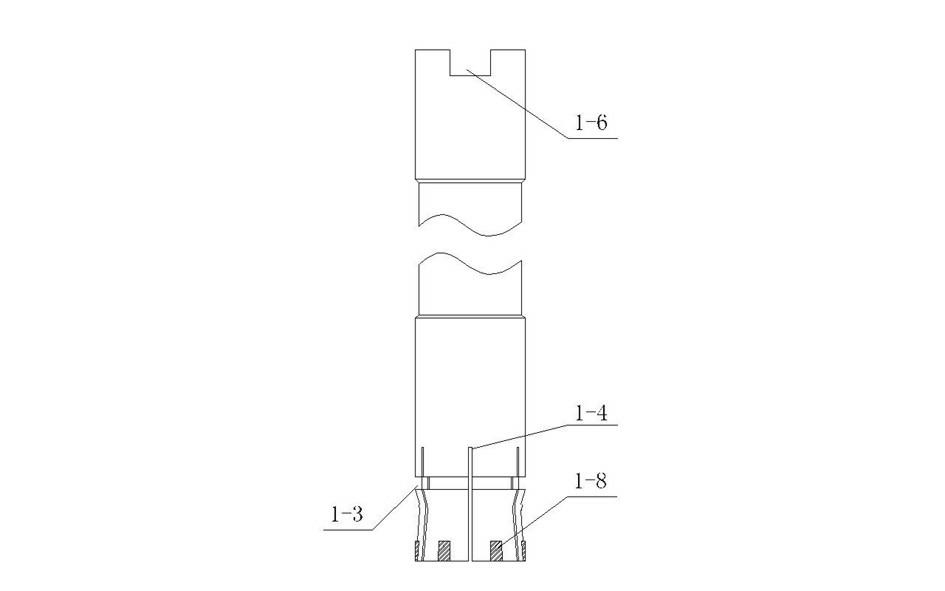

[0062] Figure 7 Shown is the third embodiment of the present invention. Compared with Example 1, the lower end of the expansion sheet is provided with two cutter teeth 1-1. The cutter teeth 1-1 have the same structure but the width is reduced. The cutter teeth 1-1 The increased density can speed up the milling frequency of the milling mechanism and increase the milling speed.

[0063] Correspondingly, a hard material milling layer is provided on the working surface of the cutter tooth 1-1. The hard material milling layer is composed of diamond or boron nitride, and a hard alloy coating can also be used. The milling layer is brazed or electroplated. Set on the working face of the cutter tooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com