Manufacturing process of facial tissue in abrasive vulcanized fiber paper

A production process and technology of face paper, applied in the field of steel paper, can solve the problems of inability to meet the strength requirements of grinding steel paper, low strength of face paper, low elongation, etc. The effect of increased length and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

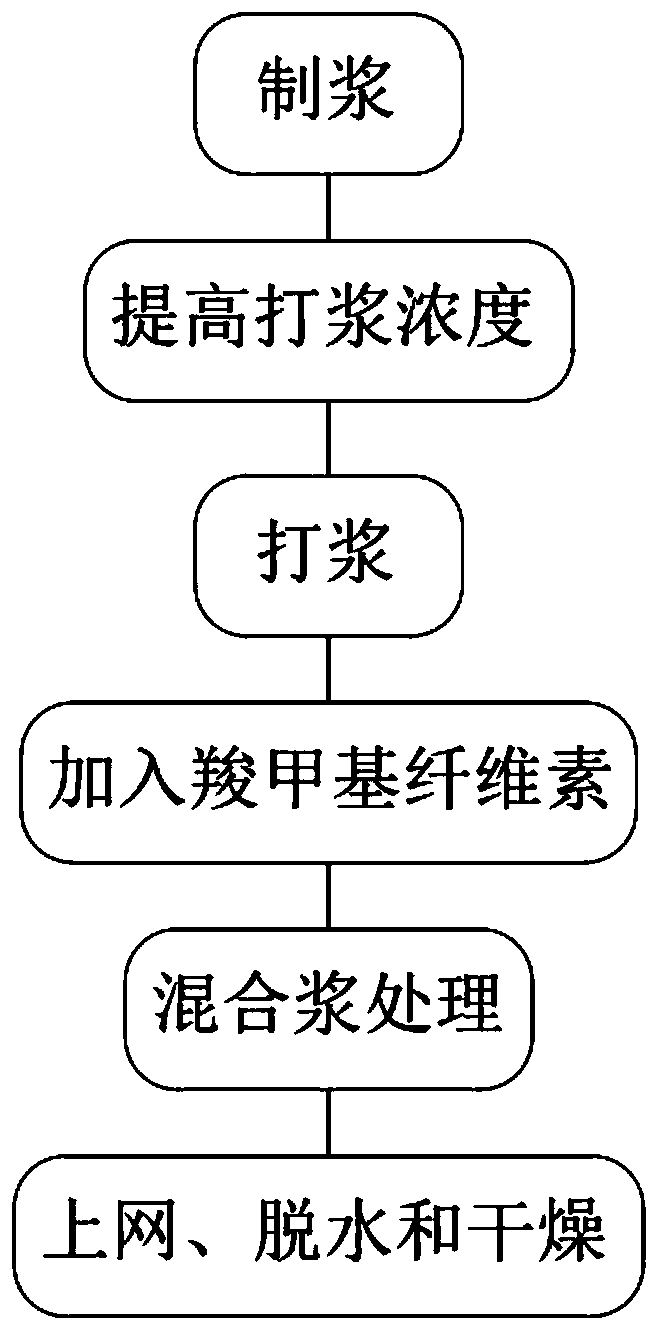

[0040] Embodiment one is basically as attached figure 2 and image 3 Shown:

[0041] A kind of manufacture technology of face paper in ground steel paper, comprises the steps:

[0042] Step 1, pulping: take cotton fibers, and pulp the cotton fibers to obtain a slurry with a beating concentration of 3% and a wet weight of 18-22g;

[0043] Step 2, increase the beating concentration: send the slurry that has passed step 1 into the thickening equipment, and the slurry flows through the upper and lower papermaking wires in the thickening equipment, and the pulp is dehydrated after being squeezed by the two papermaking wires. The beating concentration of the prepared slurry is raised to 5%;

[0044] Step 3, beating: Send the slurry that has completed step 3 into the screw propeller of the thickening equipment, and use the screw propeller to push the slurry with increased beating concentration into the disc refiner for beating treatment, and the obtained slurry beating degree is ...

specific Embodiment approach

[0051] In the prior art, the cotton fiber is subjected to low-concentration beating according to the production method of the prior art, that is, the slurry with a beating concentration of 3-3.2% is pumped into the disc refiner by a pulp pump for beating, and after the disc refiner is beaten The slurry is produced according to step 5 and step 6 in embodiment 1; compared with embodiment 1, the production method of the comparative example is that step 4 is lacking.

[0052] The beating concentration in Table 1 is the beating concentration of the pulp before entering the disc refiner, and the beating degree and wet weight are parameters after beating by the disc refiner.

[0053] The face paper produced in the prior art, the face paper produced in the comparative example and the face paper produced in Example 1 carry out the same test, and the breaking length, water absorption, air permeability, and tearing degree are all tests of the face paper obtained by production ; and the b...

Embodiment 2

[0062] Example two such as Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, Embodiment 2 specifically refines the concentration equipment used in Step 2 of Embodiment 1.

[0063] The enrichment equipment includes material box 1, frame, traction group and screw propeller 2, material box 1, frame and screw propeller 2 are installed on the ground, and traction group is installed on the frame; partitions are welded in material box 1 3. The top of the material box 1 is closed, and there is a certain distance between the bottom of the partition 3 and the bottom of the material box 1. The partition 3 divides the material box into a pulp chamber 11 and a pulp discharge chamber 12, and the bottom of the material box 1 near the pulp chamber 11 An overflow pipe is installed, and a slurry outlet is provided on the right side wall of the slurry outlet chamber 12 of the material box 1 .

[0064] The traction group includes a first traction group 4 and a second traction grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com