Three-dimensional force sensor

A sensor, three-dimensional force technology, applied in instruments, measuring force, measuring fluid pressure, etc., can solve the problem of low measurement accuracy, and achieve the effects of high precision, small inter-dimensional coupling, and low manufacturing technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

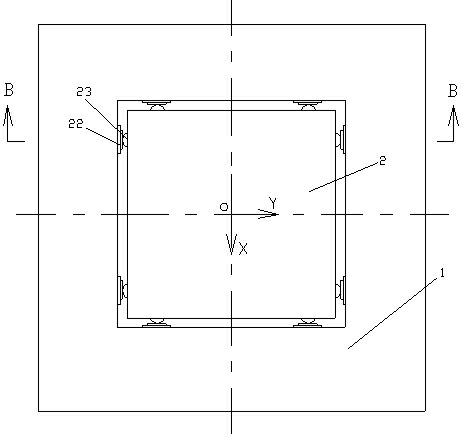

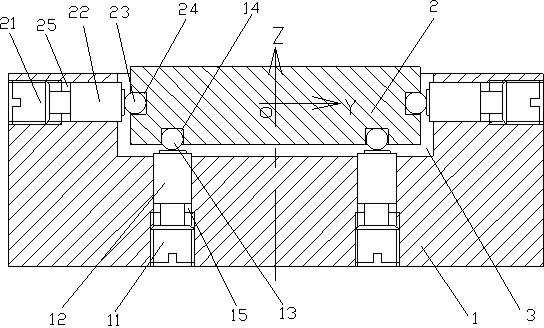

[0017] see figure 1 A three-dimensional force sensor includes a cubic sensor body 1, a square groove 3 is opened in the middle of the top surface of the sensor body 1, and a force measuring platform 2 is arranged in the square groove 3. see figure 2 The bottom of the square groove 3 of the sensor body 1 is evenly provided with four vertical through holes 15 of the same size, the axes of the four vertical through holes 15 are parallel to each other and perpendicular to the square groove 3; the bottom of the vertical through hole 15 is Vertical threaded hole, cooperate with vertical threaded hole to be equipped with vertical adjustment screw 11, be provided with vertical one-dimensional force sensor 12 and vertical steel ball 13 upwards successively in the vertical threaded hole of the top of every vertical adjustment screw 11, with each vertical steel ball The bottom surface of the force measuring platform corresponding to the ball is provided with a bottom positioning blind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com