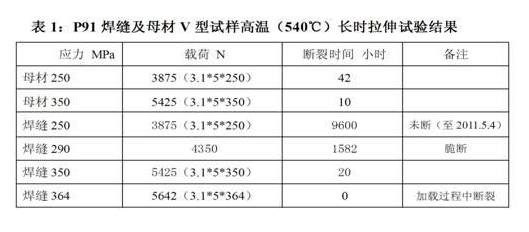

Test specimen for high-temperature strength and notch sensitivity of welding seam

A high-temperature strength and sensitivity technology, applied in the field of material science, can solve the problems of fracture in the heat-affected zone, inability to know the lateral properties of the weld metal, and difficult to measure the real properties of the weld metal, achieving great social benefits and Economical, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

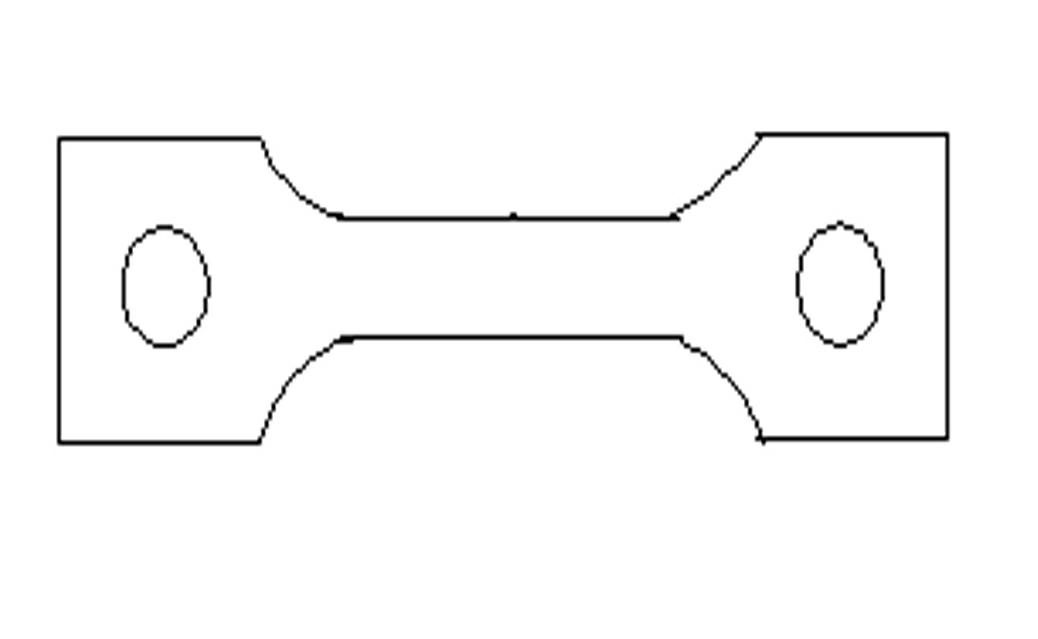

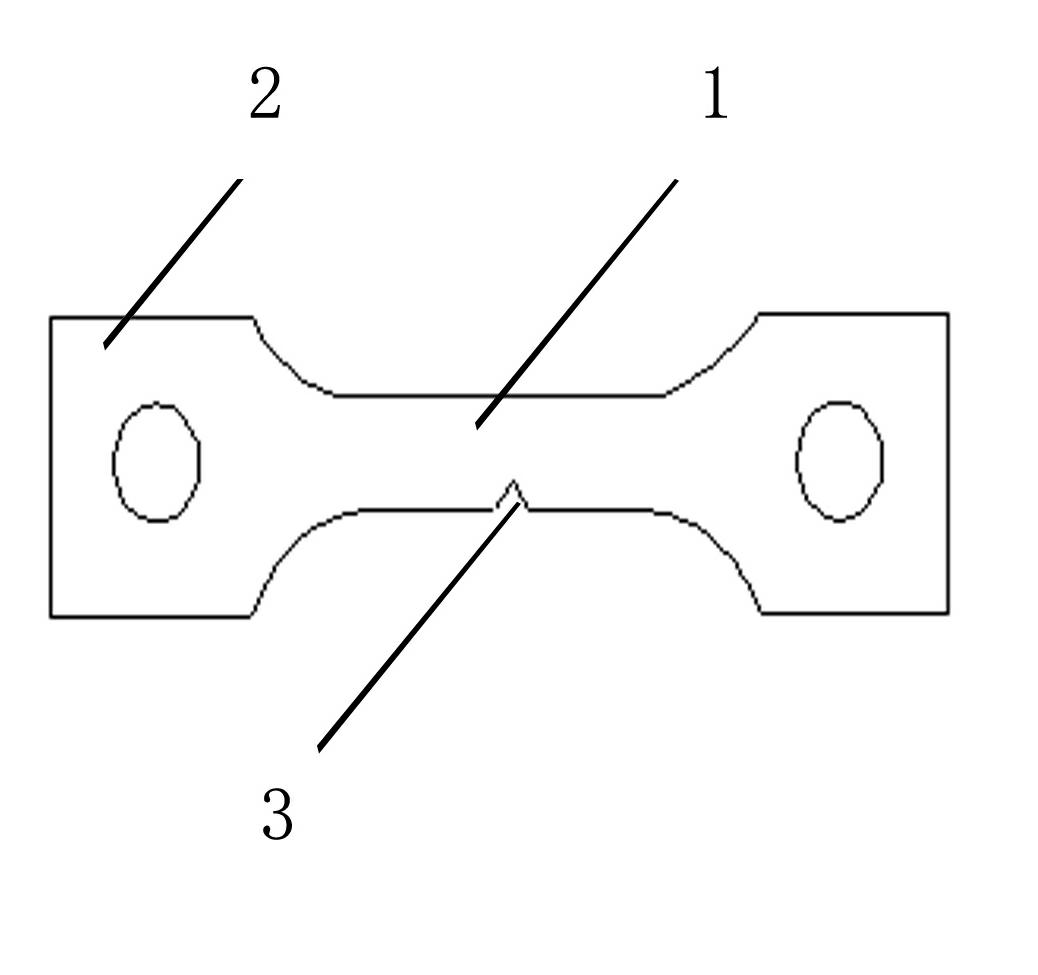

[0023] The present invention is the high-temperature strength of weld seam and its notch sensitivity test sample, such as figure 2 As shown, the sample 9 of the present invention is strip-shaped and the same as the conventional long-lasting sample, with thick ends and a thin middle structure; the two ends are clamping ends 2, the middle is a test section 1, and the clamping ends 2 at both ends The direction to the middle test section 1 is an inwardly recessed smooth transition section, wherein the middle part of the test section 1 is provided with a notch 3 .

[0024] The notched sample weld performance test sample of the present invention has the same test operation steps as the conventional high-temperature long-term tensile test method, and the difference is that the sample is made, such as figure 2 As shown, the sample of the present invention is a long strip type, the two ends are clamping sections and the same as the conventional durable sample, the middle is a test se...

Embodiment 2

[0028] A rectangular cross-section P91 weld sample is used, and the cross-sectional size of the test section sample is 7×3mm. The gap is opened on the weld seam, the opening depth is 2mm, and the opening width is 2mm. The test temperature is 540°C, the test stresses at the notches of the four samples are 364MPa, 350MPa, 290MPa, and 250MPa respectively, and the fracture times of the samples are 0, 20, 1582, and 9600 hours, respectively. Figure 4 to Figure 6 shown.

[0029] A P91 base metal sample with a rectangular cross-section is used. The cross-sectional size of the sample in the test section is 7×3mm. The gap is opened in the middle of the test section with a depth of 2mm and a width of 2mm. The test temperature is 540°C, the test stresses at the notches of the two samples are 350MPa and 250MPa respectively, and the fracture times of the samples are 10 and 4220 hours respectively.

[0030] It can be seen that the fracture time of the P91 weld samples with test stresses of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com