Automatic test apparatus for friction voltage

An automatic test equipment, electrostatic test technology, applied in the direction of measuring current/voltage, measuring devices, measuring electrical variables, etc., can solve the problems of large error and poor repeatability of manual test results, and reduce the interference of external environment and human factors, Achieve full automation, ensure accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiments.

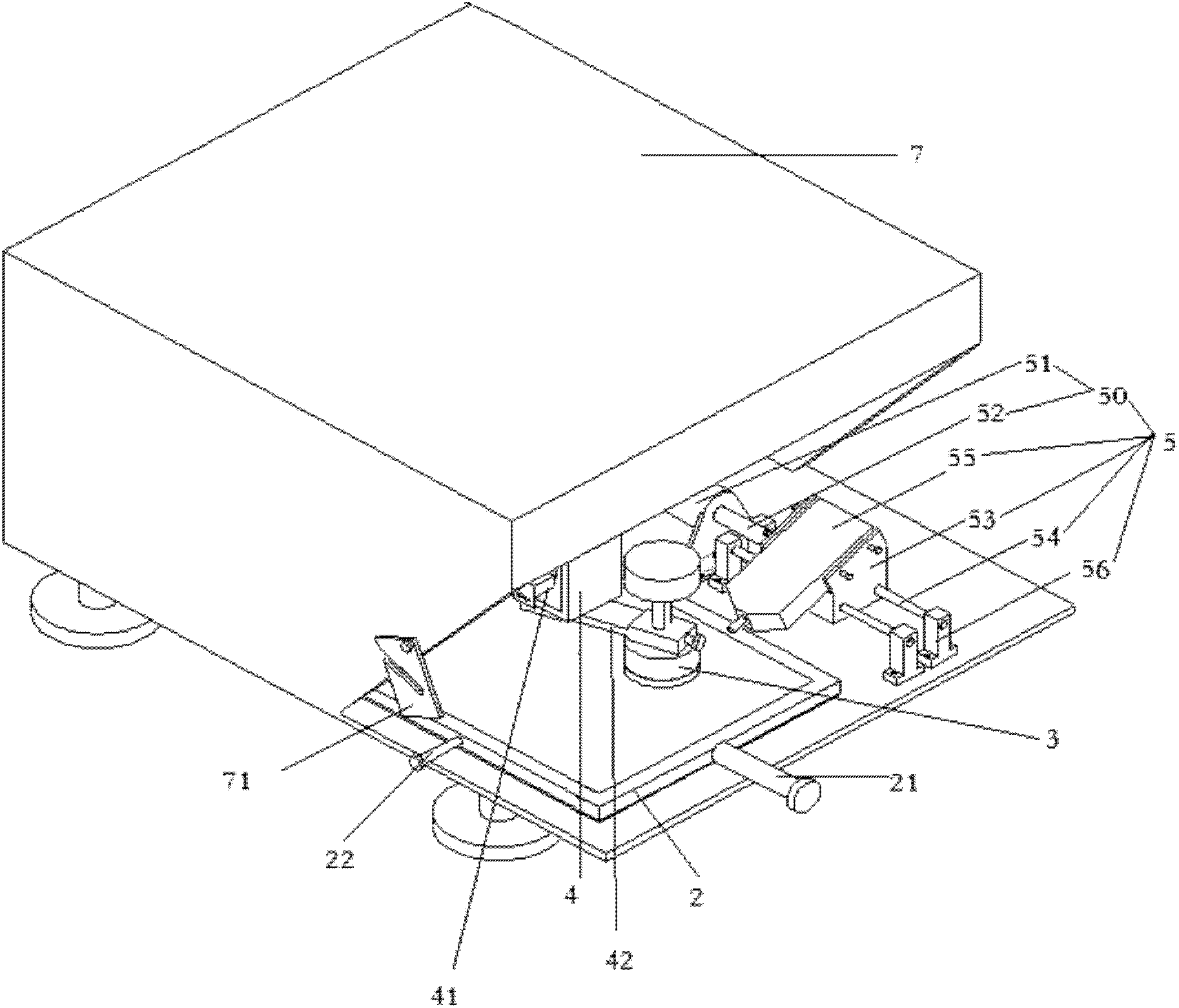

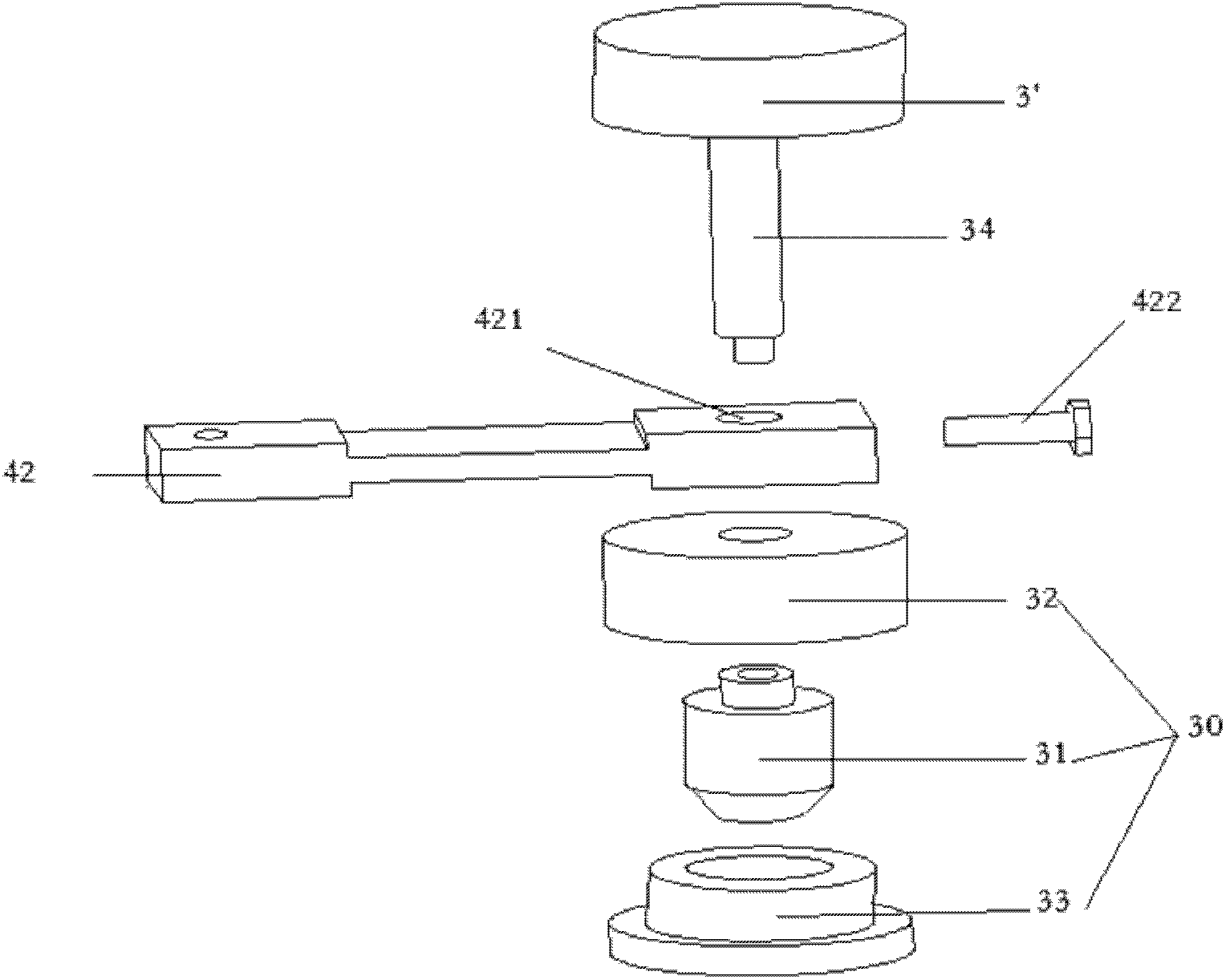

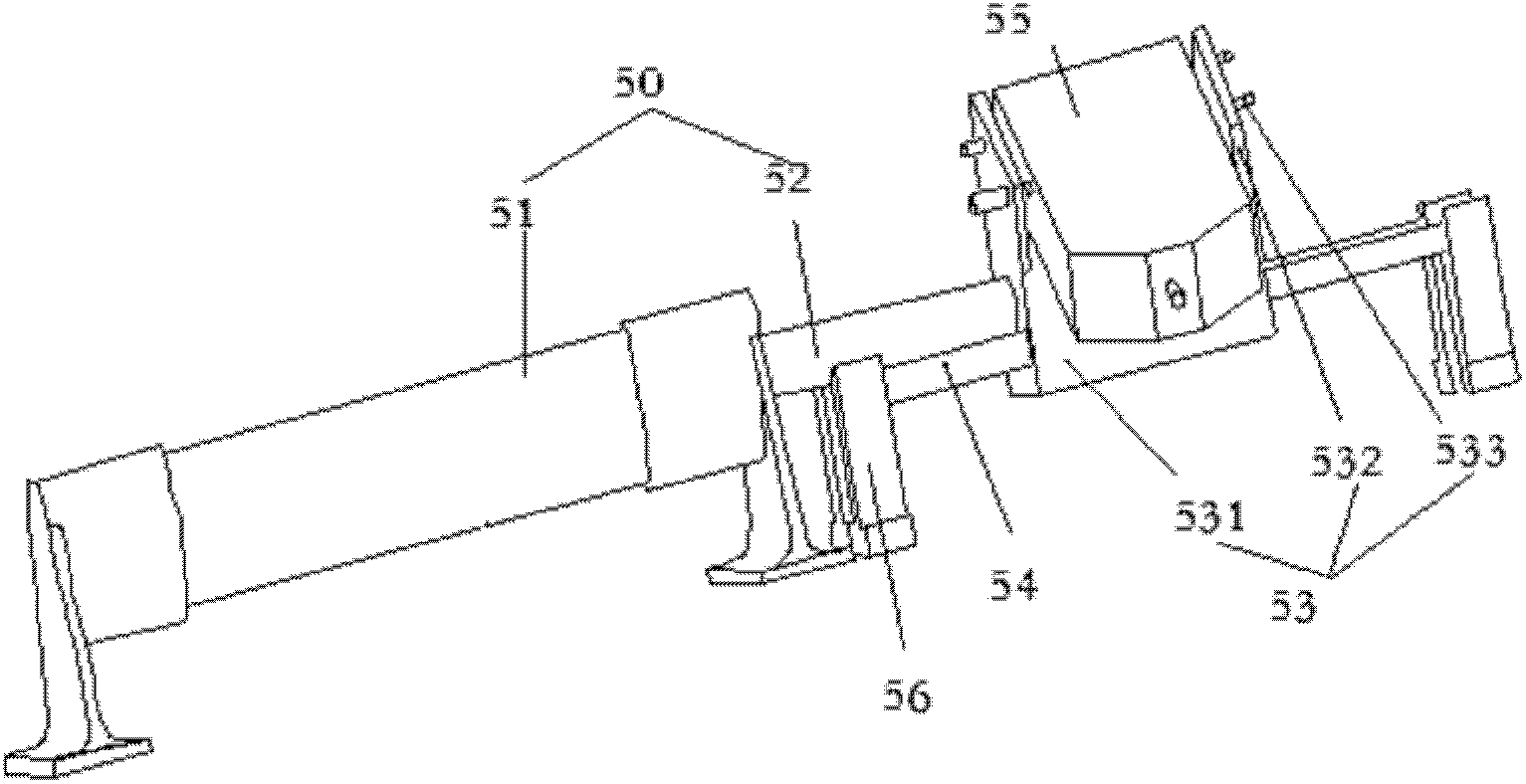

[0019] Such as figure 1 As shown, a friction voltage automatic test equipment includes a frame 7, a base 1 is arranged at the lower part of the frame 7, and a friction device for rubbing the tested sample on the base 1 is arranged on the frame 7 3. The friction device 3 includes a friction member 30 for contacting and rubbing with the test sample on the base 1 and a first driving mechanism 4 for driving the friction member 30 to move; the friction voltage automatic test equipment also includes The test device 5 for the friction voltage of the tested sample. The test device 5 includes an electrostatic test instrument 55 and a second driving mechanism 50 for driving the electrostatic test instrument 55 to move. The friction device 3 and the test device 5 are connected to A control device (not shown in the figure) that controls the actions of both.

[0020] The base 1 is used to place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com