Online monitoring system of high-voltage equipment

A high-voltage equipment and monitoring system technology, applied in the field of monitoring systems, can solve the problems of deploying many professional testing personnel, unable to supply power, consuming a lot of manpower and material resources, saving manpower and material resources, ensuring safe and stable work, and being flexible and expandable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The invention discloses an online monitoring system for high-voltage equipment, which is used for real-time monitoring of high-voltage equipment in substations distributed in various regions in a grid system.

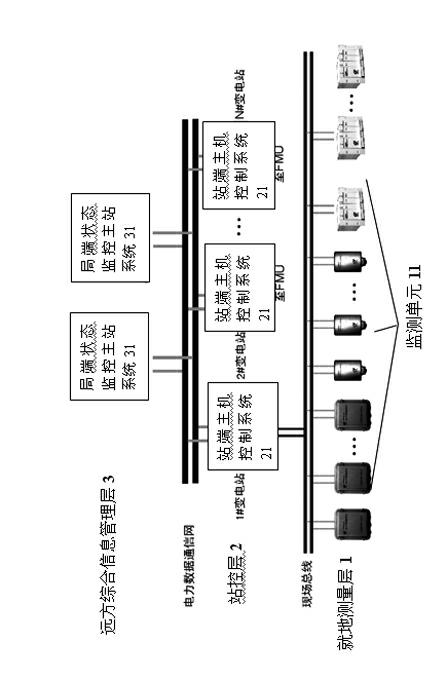

[0017] Such as figure 1 As shown, the high-voltage equipment on-line monitoring system adopts a three-layer system structure, which is designed according to a layered distributed system. The building block structure has flexible scalability. The system includes an on-site measurement layer 1, a station control layer 2 connected to the on-site measurement layer 1 through the RS485 industrial field bus network, and a remote integrated information management layer 3 connected to the station control layer 2 through a power data communication network network.

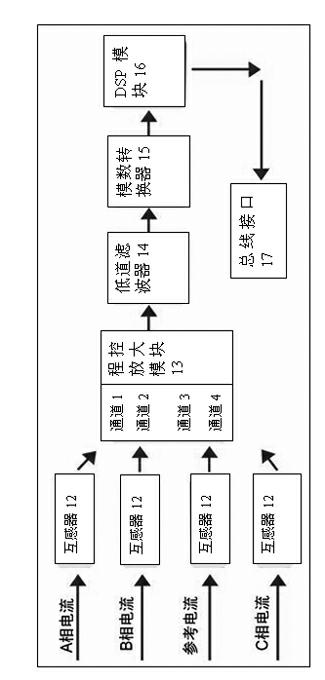

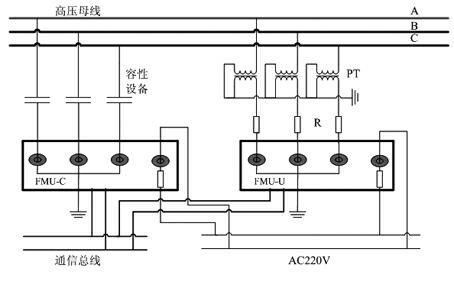

[0018] The on-site measurement layer 1 includes a number of monitoring unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com