Electricity-saving economical double-layer civil-engineering novel refrigeration house

An economical and cold storage technology, applied in construction, refrigeration plants, building components, etc., can solve the problems of damage to reinforced concrete, high construction costs, easy soaking and cold conduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

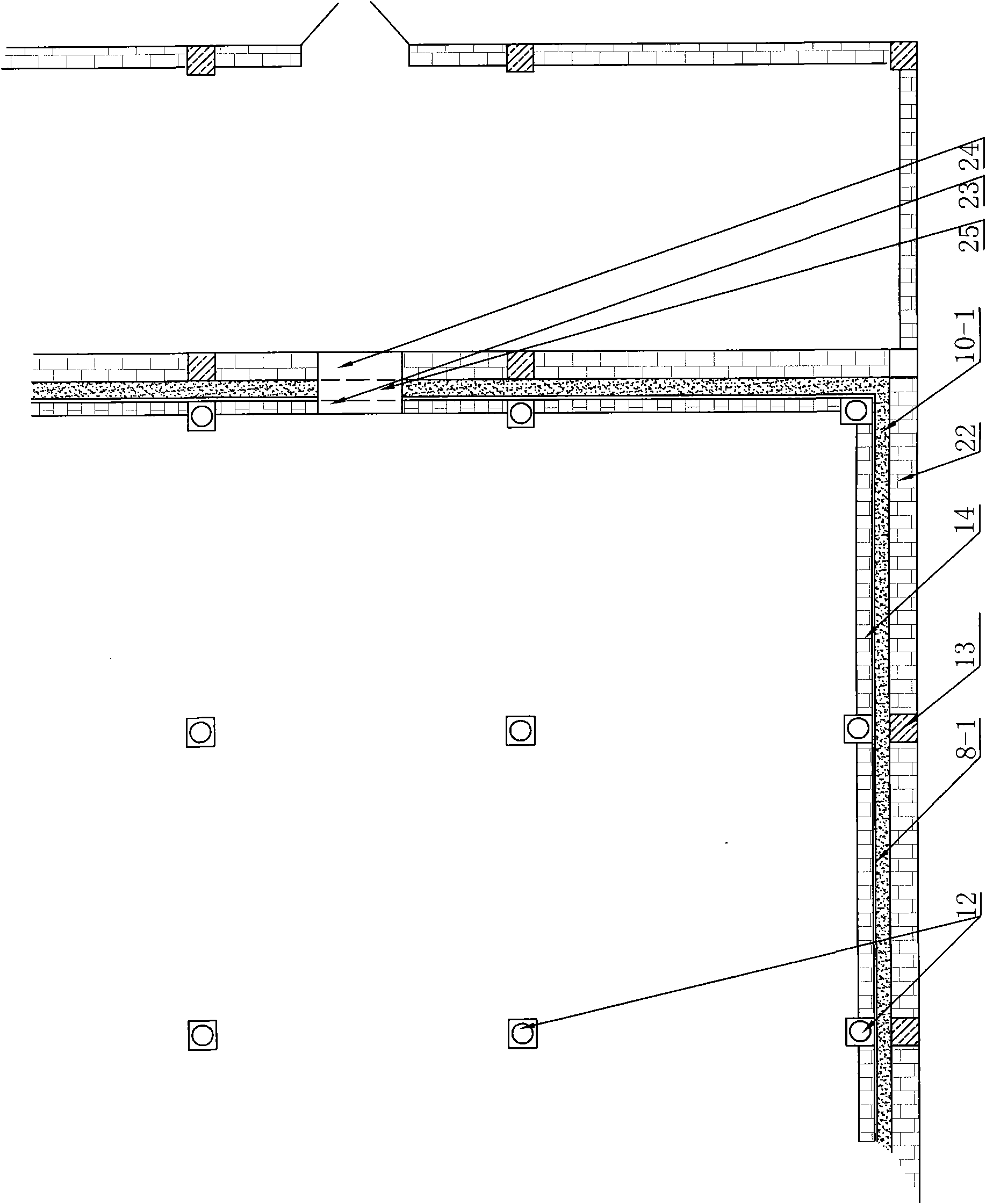

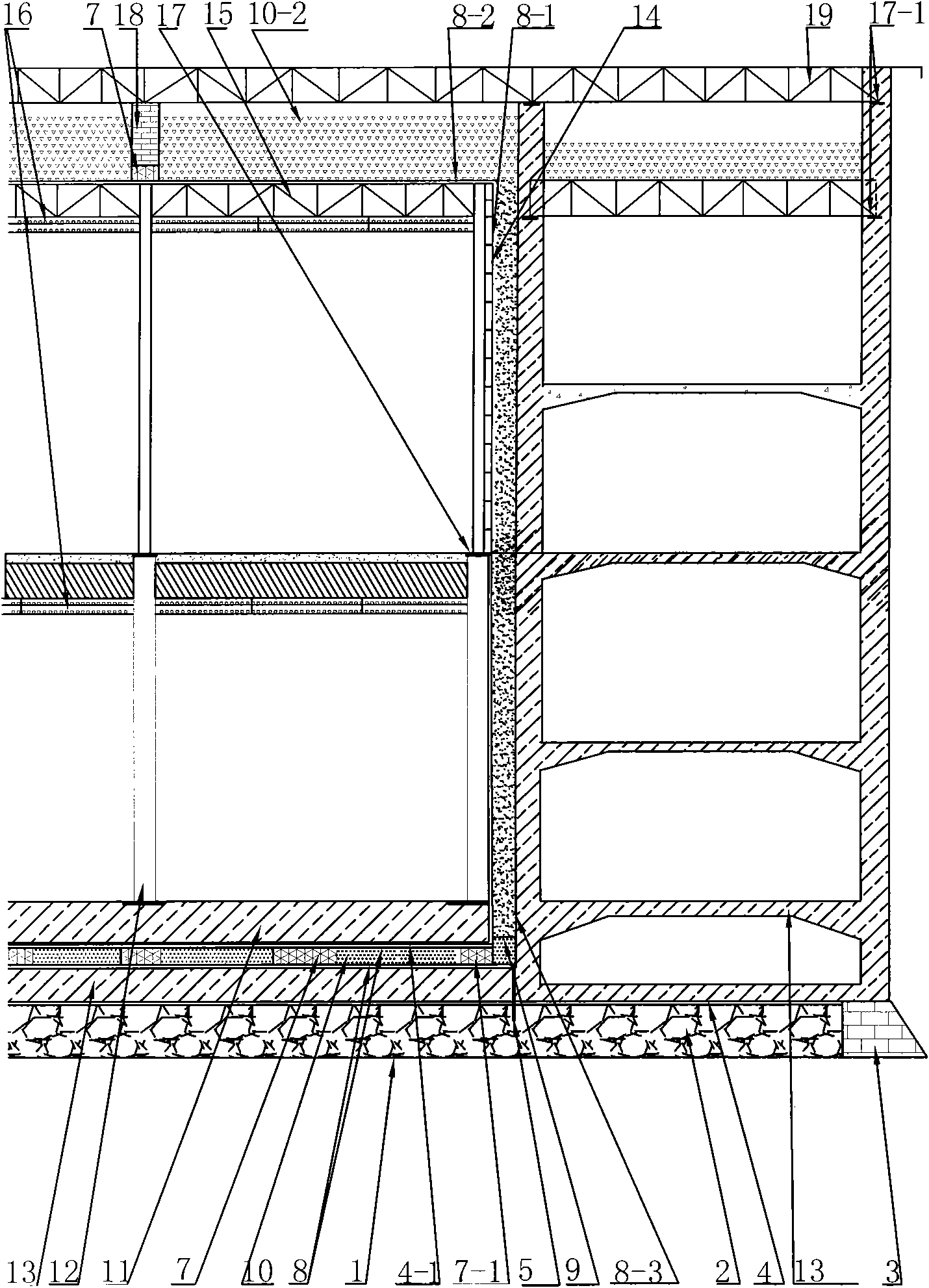

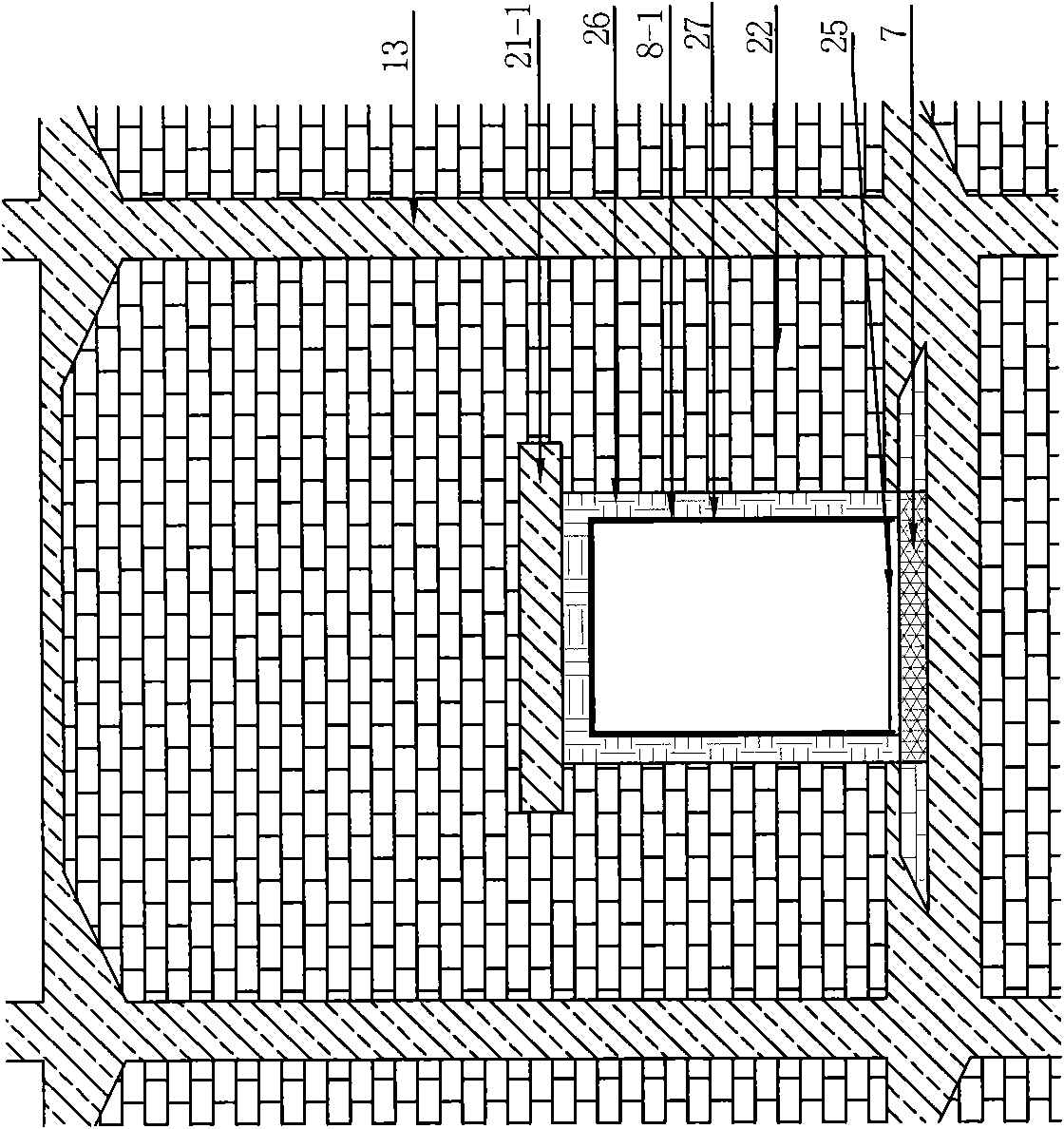

[0045] Such as figure 2 Shown: Carry out all excavation and excavation above the required original hard layer 1; then carry out stone masonry with saturated mortar for the wall base; then carry out construction of the cobblestone sand-shaking layer within 3 of the wall-base saturated mortar masonry, and the cobblestone sand-shaking layer 2 is Water shaking vibration rolling construction; after that, the cement mortar cushion layer 4 on the cobblestone sand shaking layer is constructed, and at the same time, the drainage pipe 5 around the thick trough-shaped reinforced concrete foundation 6 is inserted into the pebble sand shaking layer 2 and the cement mortar cushion is reserved The thickness of the thick trough-shaped reinforced concrete foundation above the first floor is high; after that, the thick trough-shaped reinforced concrete foundation and the reinforced concrete column foundation of the freight elevator building will be constructed to exceed the height of the yard; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com