Manufacturing method for an optical connector

A manufacturing method and technology of optical connectors, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

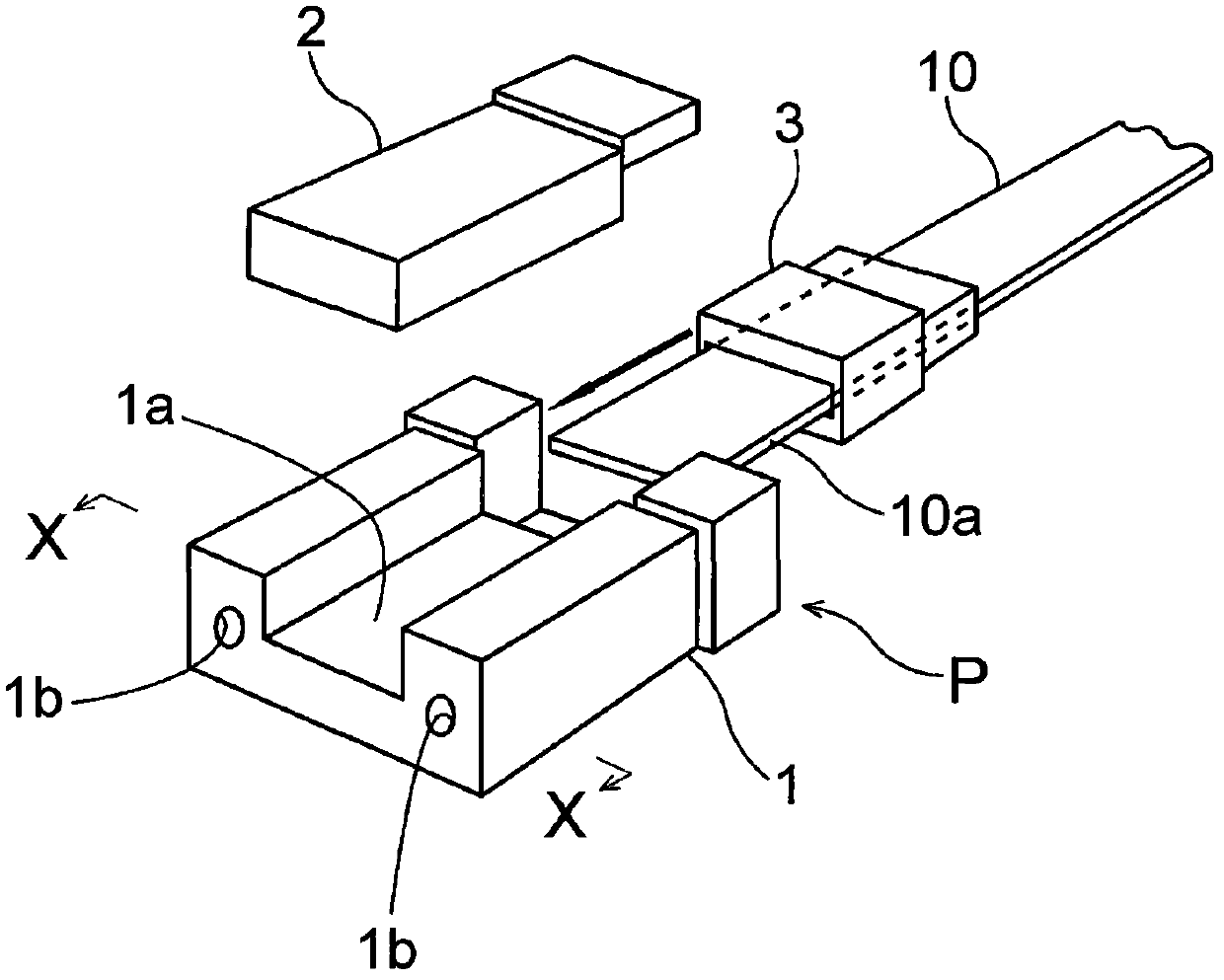

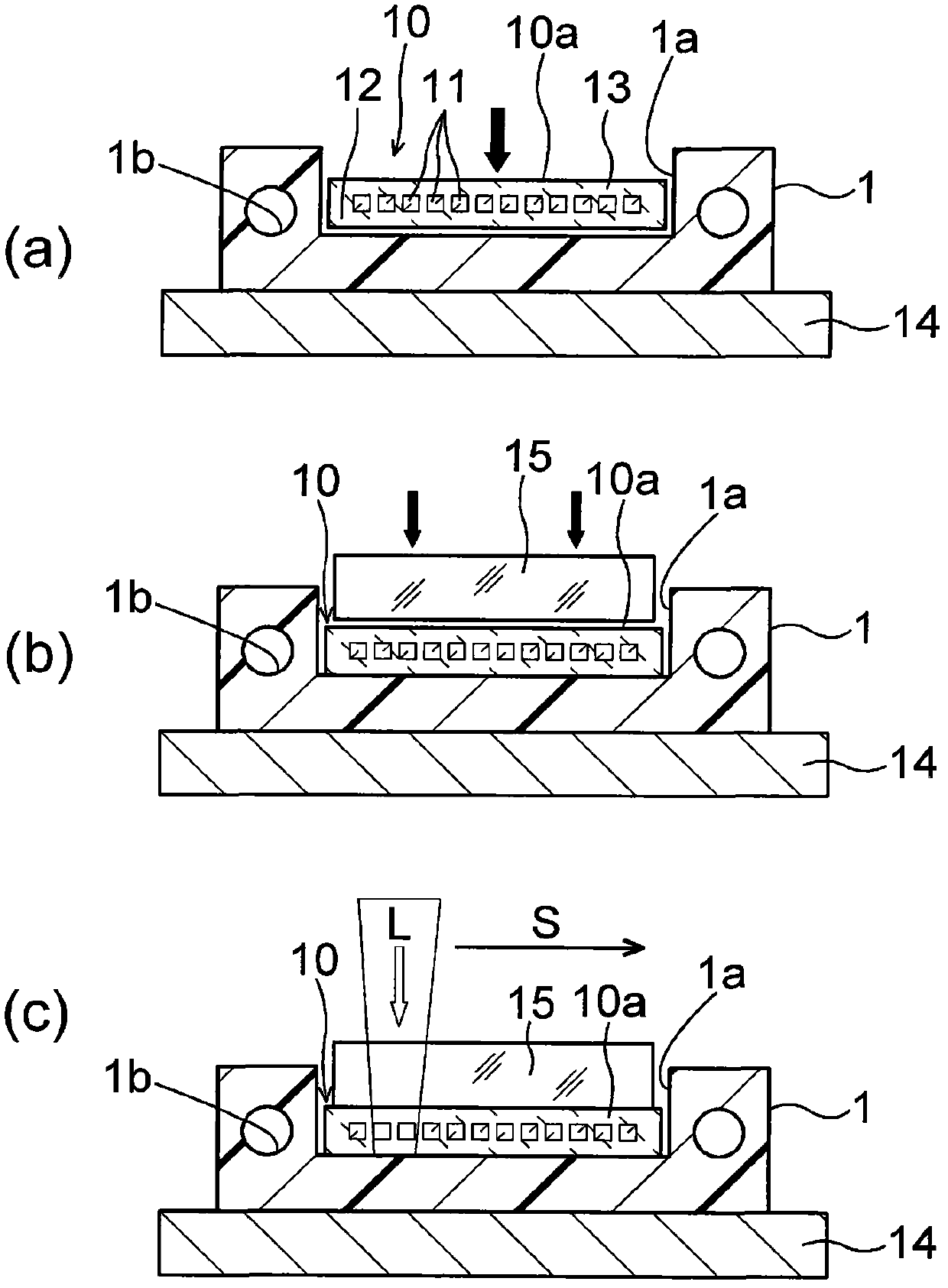

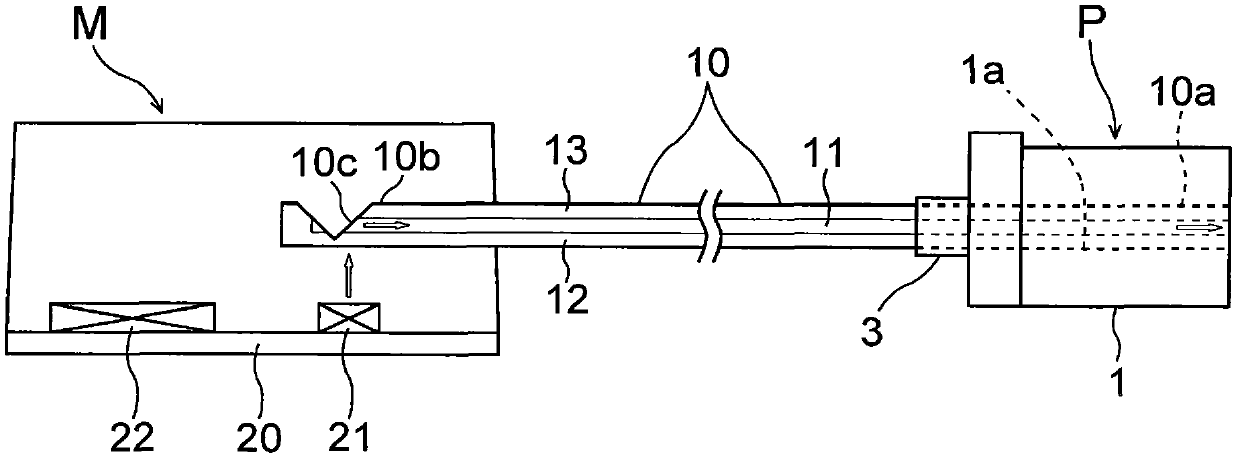

Method used

Image

Examples

Embodiment

[0049] Next, Examples will be described with reference to Comparative Examples. However, the present invention is not limited to the following examples.

[0050] In this embodiment, a polymer optical waveguide is fabricated by photolithography, and one end of the polymer optical waveguide is fixed to a commercially available PMT connector using a near-infrared laser. In addition, when using the same optical waveguide to fabricate the optical connector of the comparative example in which the end of the optical waveguide is fixed to the PMT connector with an adhesive, the insertion loss and The insertion loss "after mounting the joint" (after performing grinding in the comparative example) was compared. In addition, the measurement of insertion loss was performed in accordance with Japanese Industrial Standard JIS C 5961 "Test methods for optical fiber connectors".

[0051] Before proceeding to the examples, first, an optical waveguide for a test was fabricated.

[0052] Fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com