Industrial energy-saving monitoring system based on wireless sensor network

A wireless sensor and monitoring system technology, applied in the field of electronic information, can solve the problem of considering energy use efficiency in the three-level mode, and achieve the effect of reducing permanent lights, improving the subjective initiative of energy saving, and promoting the awareness of energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

[0044] First, the system structure and hardware composition of the present invention will be described in detail.

[0045] The system structure in the present invention is introduced below.

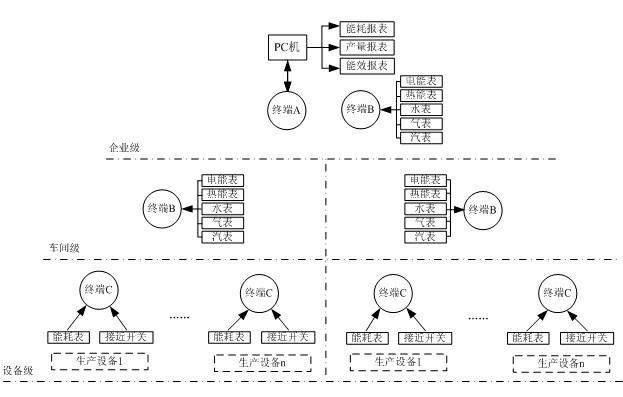

[0046] as attached figure 1 As shown, the present invention provides an industrial energy-saving monitoring system based on a wireless sensor network. The system consists of a coordinator terminal A, an energy consumption data collection terminal B, an equipment data collection terminal C, a monitoring host connected to the coordinator A, and an energy consumption The energy consumption meter connected to the data collection terminal B (such as electric energy meter, water meter, heat meter, etc.), and the energy consumption meter and production counting sensor connected to the equipment data collection terminal C are composed.

[0047] as attached figure 1 As shown, the deployment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com