Container crane apparatus and container loading/unloading method using same

A technology for lifting devices and containers, applied to cranes, safety devices, trolley cranes, etc., can solve the problems of multi-loading and unloading operation time, multi-operation time, and prolonging the time of container 3 loading and unloading operations, so as to reduce fuel consumption and carbon dioxide Discharge volume, minimization of mutual waiting time, and effect of shortening waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, a container lifting device provided by an embodiment of the present invention will be described with reference to the accompanying drawings.

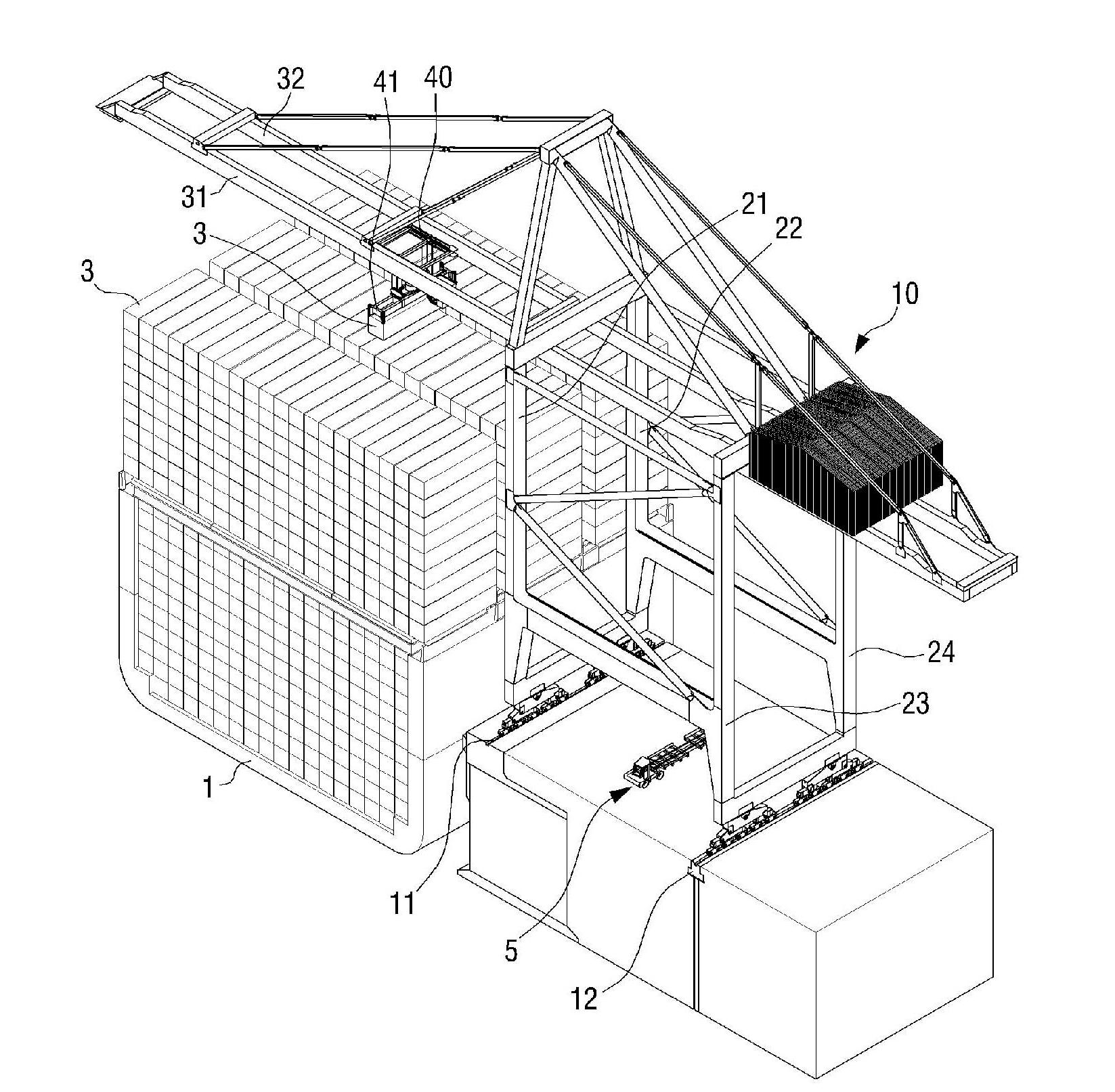

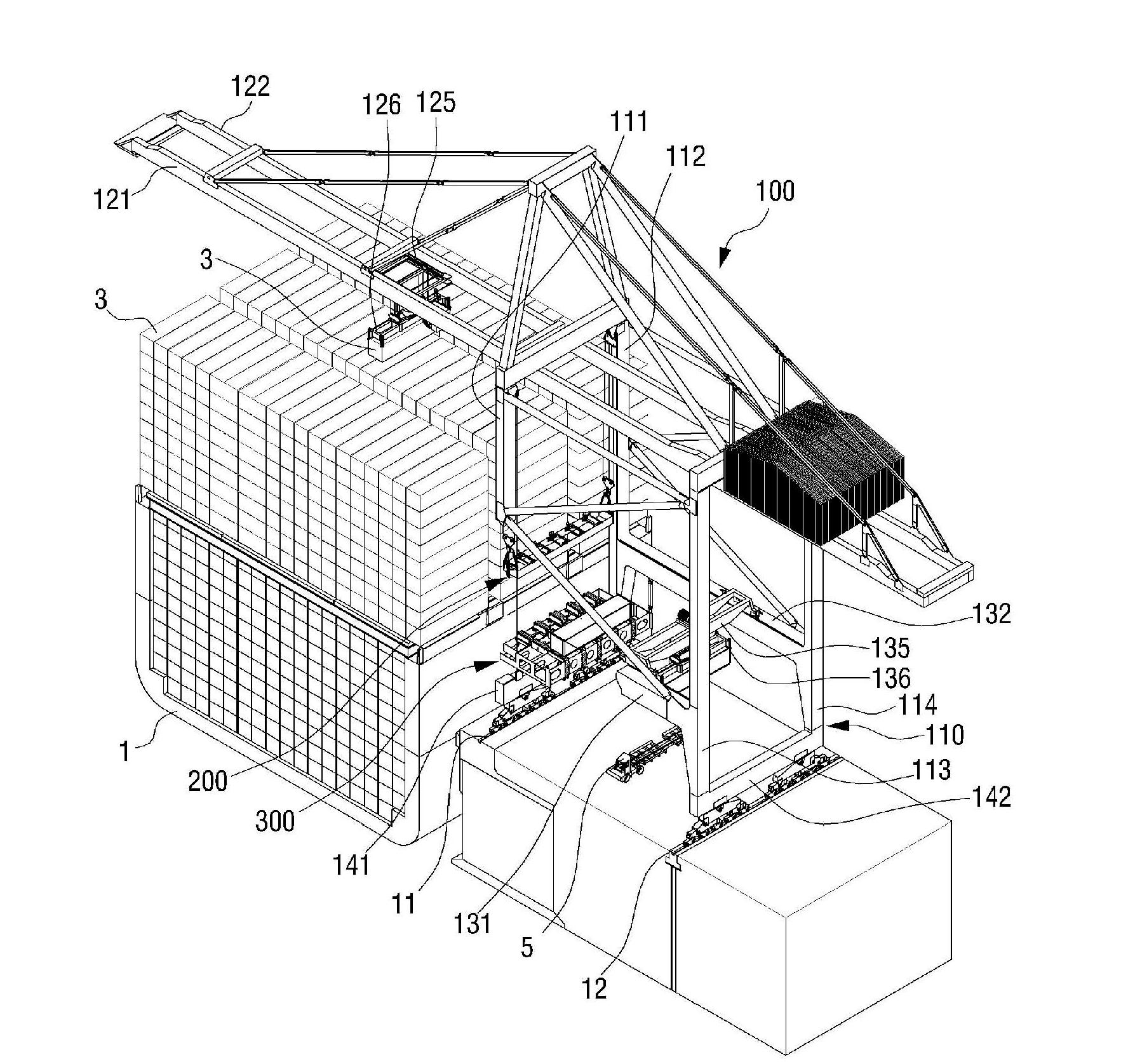

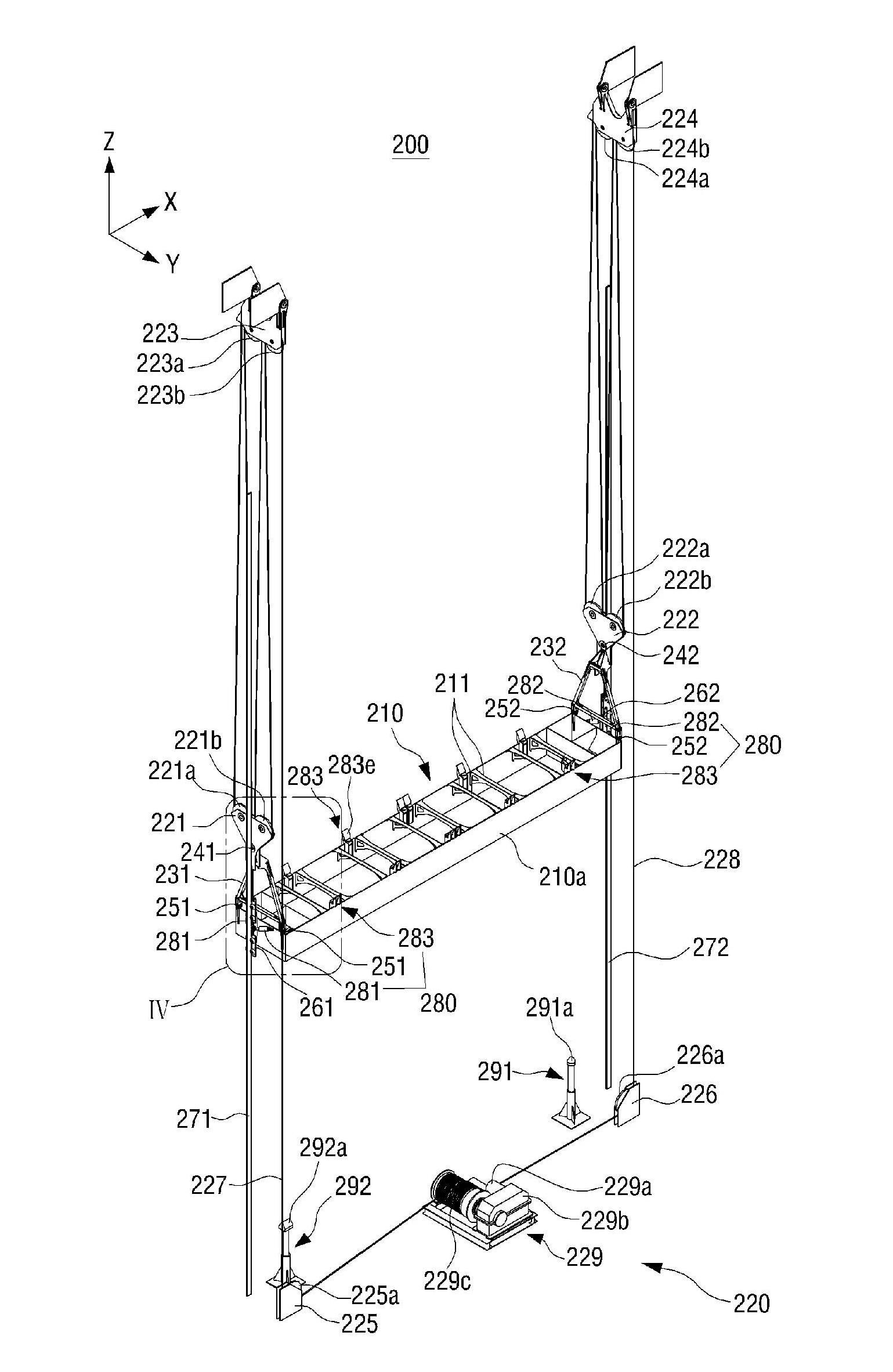

[0062] refer to figure 2 , The container lifting device 100 provided by an embodiment of the present invention includes a steel frame structure 110 , a vertical transfer unit 200 and a horizontal transfer unit 300 .

[0063] Steel frame structure 110 includes vertical structures 111 - 114 , arms 121 , 122 , support structures 131 , 132 , and base structures 141 , 142 .

[0064] A pair of vertical structures 111, 112 among the vertical structures 111-114 are located on the sea side adjacent to the container ship 1, and the remaining pair of vertical structures 113, 114 are located on the land side at a predetermined distance from the sea side vertical structures 111, 112 . At this time, a space where the trailer 5 can be parked to load and unload the container 3 is provided between the seaside vertical structures 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com