Cutting method for tobacco leaf segmenting, threshing and redrying

A technology for threshing and redrying and tobacco leaves, which is applied in the fields of tobacco, analysis of materials, and tobacco processing. The effect of cutting according to the objective, scientific cutting design and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

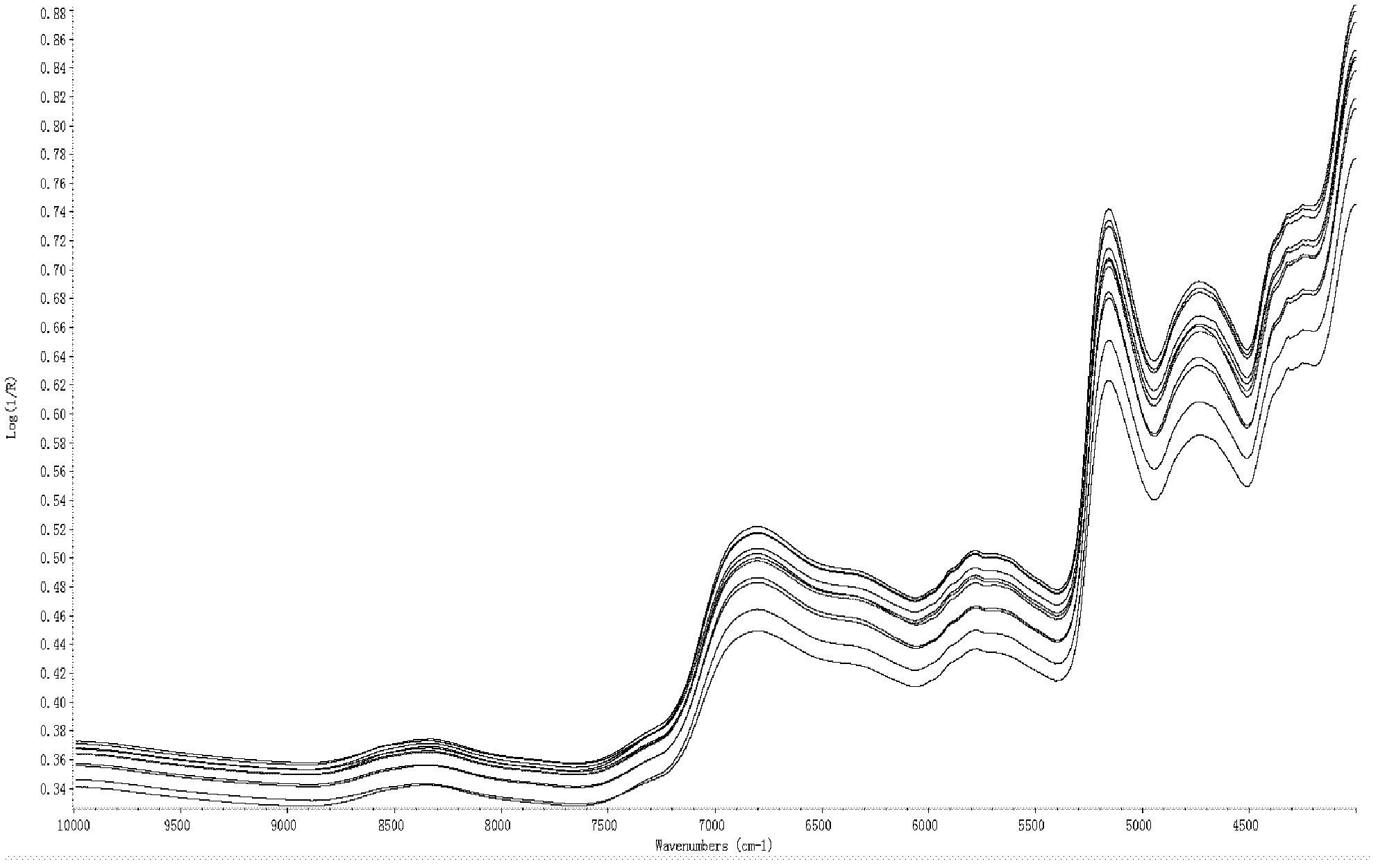

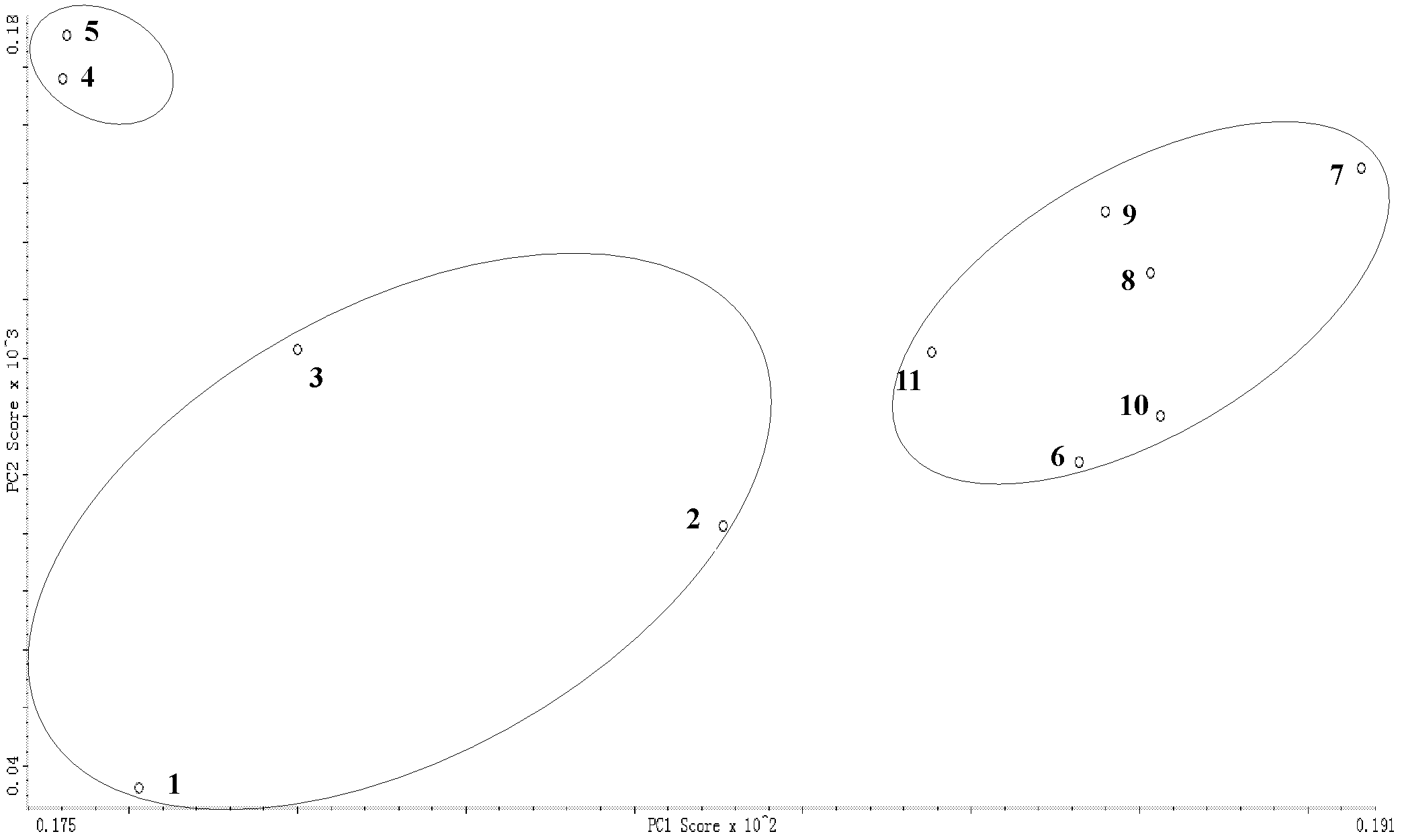

[0021] 5Kg of C3F grade tobacco leaves of K326 variety were randomly selected from the rebaking and finishing workshop. Through measurement, the length of the tobacco leaves was in the range of 57 to 60 cm. Based on the length of the main vein, it was cut into 11 sections using the 0.618 golden section method, and each section was divided into 40 cm. Dry at ~45°C, pulverize, and pass through a 60-mesh sieve to make samples. The prepared sample was scanned by a Nicolet Antaris Fourier transform near-infrared spectrometer with a spectral resolution of 4cm, a scanning range of 4000-10000cm, and a scanning frequency of 72 times. Moisture and CO were removed immediately during scanning. 2 background interference. The near-infrared spectra were collected and processed by the TQ analyst 7.0 quantitative analysis software that comes with the near-infrared spectrometer, and the near-infrared spectra of each section of K326 C3F smoke samples were obtained ( figure 1 ).

[0022] agains...

Embodiment 2

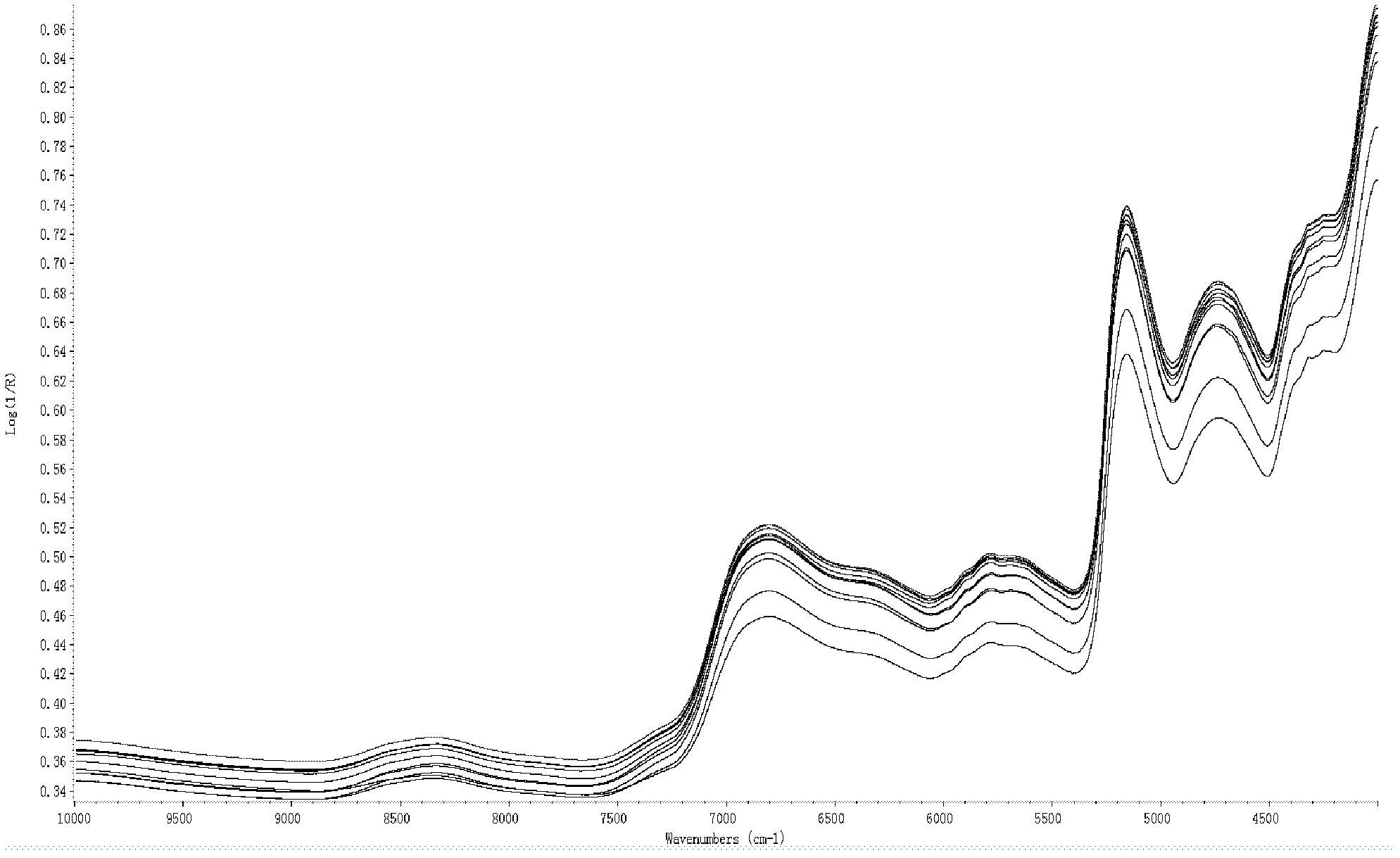

[0024] Randomly select 5Kg of tobacco leaves of C3F grade red variety from the rebaking and finishing workshop. Through measurement, the length of the tobacco leaves is in the range of 63-65cm. Based on the length of the main vein, it is divided into 11 sections using the 0.618 golden section method. Each section of the sample is in the Dry at 40-45°C, pulverize, and pass through a 60-mesh sieve to make samples. The prepared sample was scanned by a Nicolet Antaris Fourier transform near-infrared spectrometer with a spectral resolution of 4cm, a scanning range of 4000-10000cm, and a scanning frequency of 72 times. Moisture and CO were removed immediately during scanning. 2 background interference. After collecting and processing the near-infrared spectrum with the TQ analyst 7.0 quantitative analysis software that comes with the near-infrared spectrometer, the near-infrared spectrum of each segment of the Hongda C3F smoke sample was obtained ( image 3 ).

[0025] against i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com