Multi-behavior process monitoring method based on pivot analysis and vectorial data description support

A data description, support vector technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of false alarms and omissions in the transition part of working conditions, large amount of calculation, decreased sensitivity of process changes, etc. The effect of tightening statistical limits, troubleshooting, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

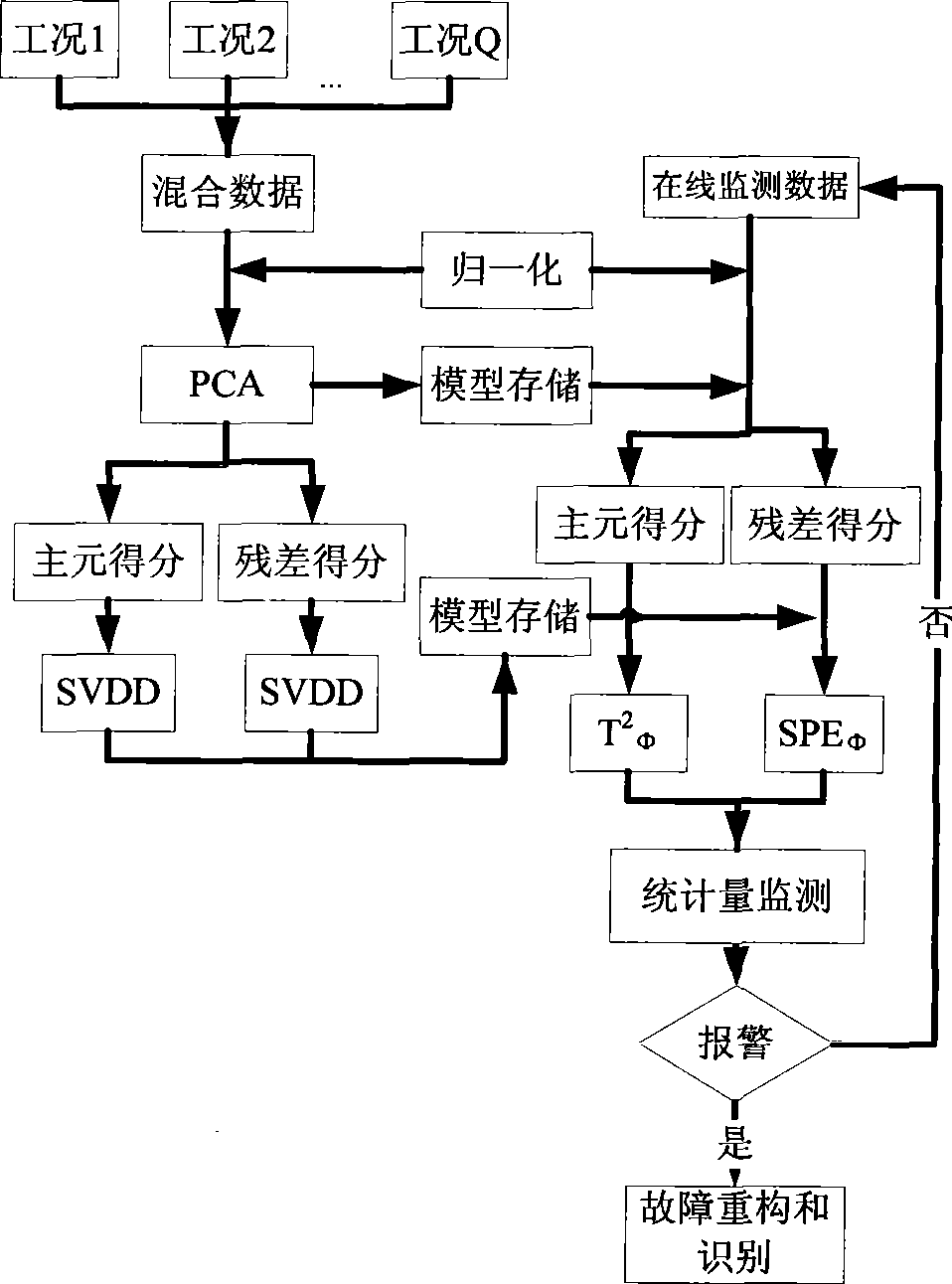

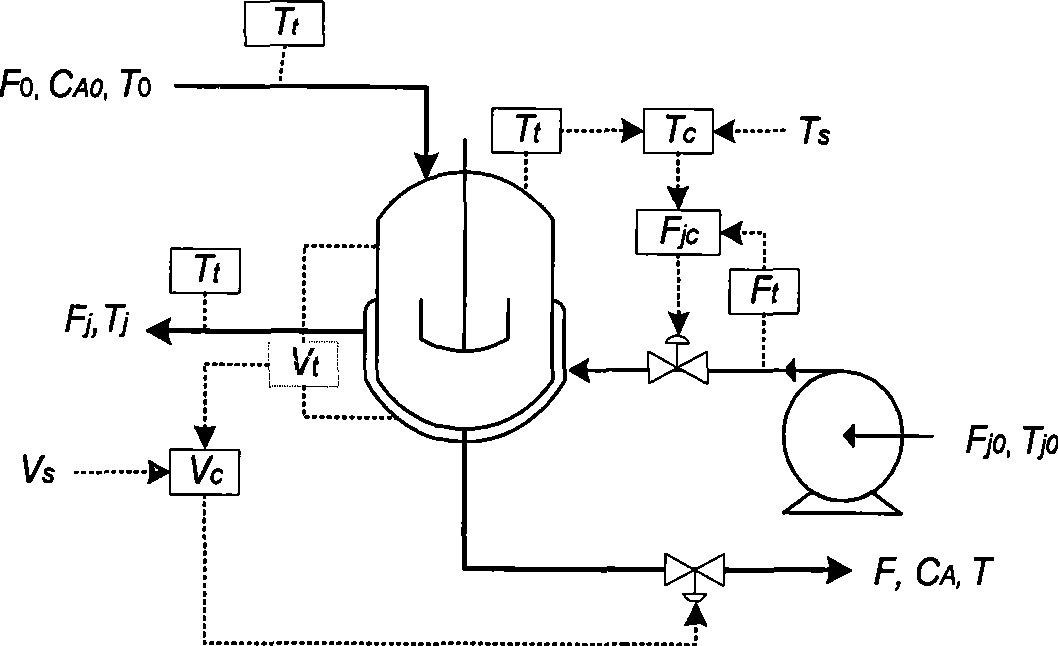

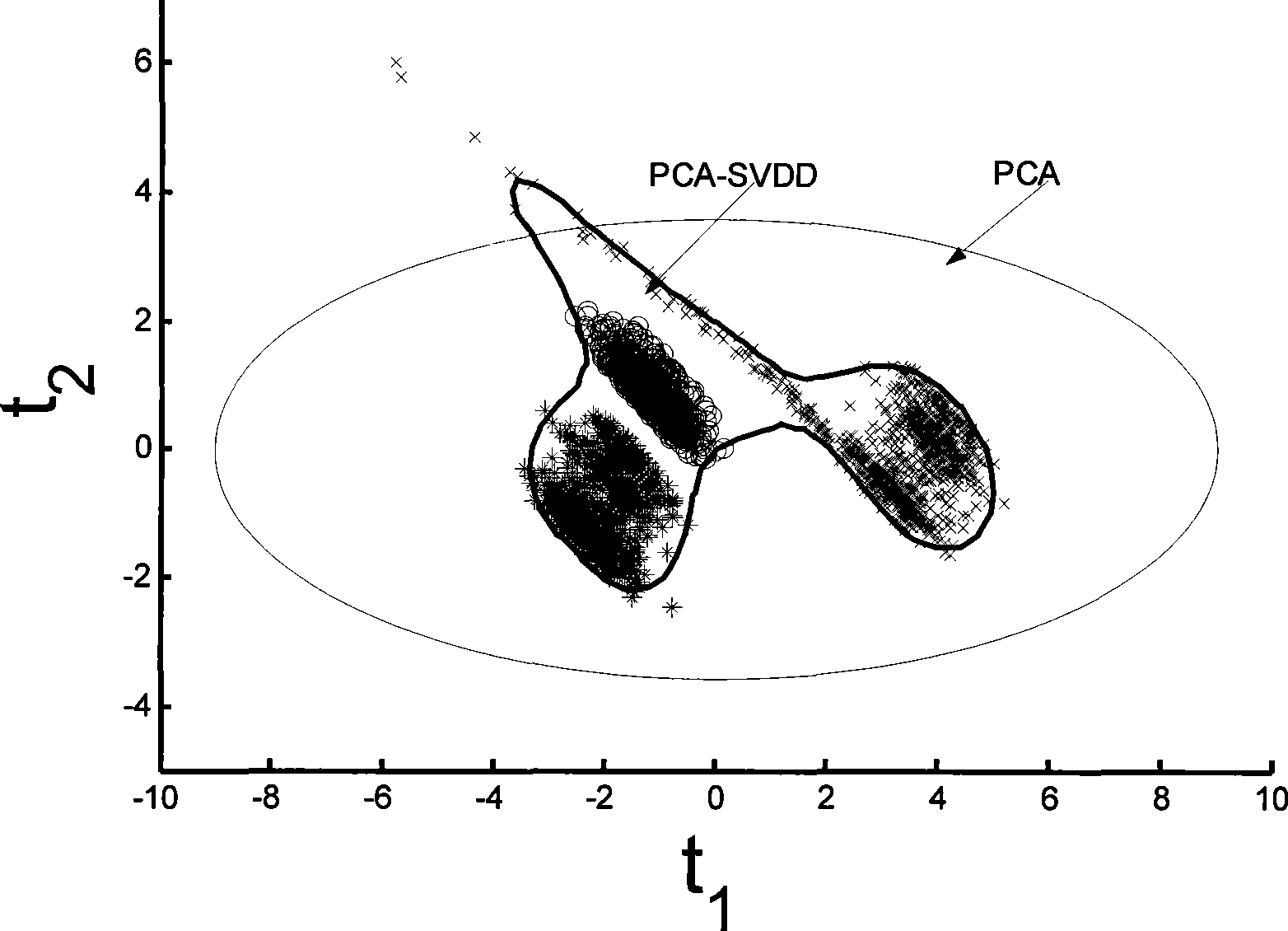

[0018] The present invention aims at the problem of multi-working conditions in industrial process monitoring. First, a unified principal component analysis (PCA) statistical monitoring model is established by using all normal working condition data, which is used for information extraction and dimensionality reduction of process data, and the PCA statistical model structured as X = TP T + T ~ P ~ T = TP T + E , where X is the process data matrix, T, P are the principal component score and loading matrices, is the residual score and loading matrix, E is the residual matrix, and the number of principal components of PCA can be selected by cross-validation method or cumulative variance contribution rate (CPV) method. The principal compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com