Diode straighter with double rubber rollers

A diode and straightening machine technology is applied in the field of straightening diode pins of electronic components, which can solve the problems of low work efficiency and poor quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

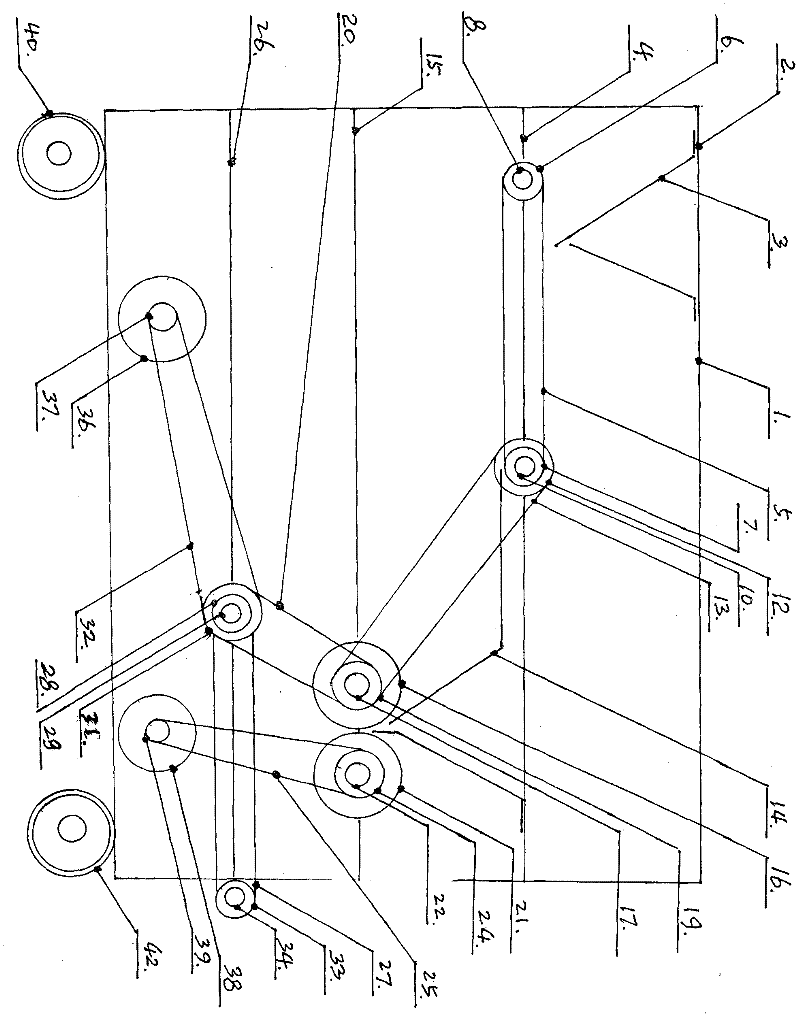

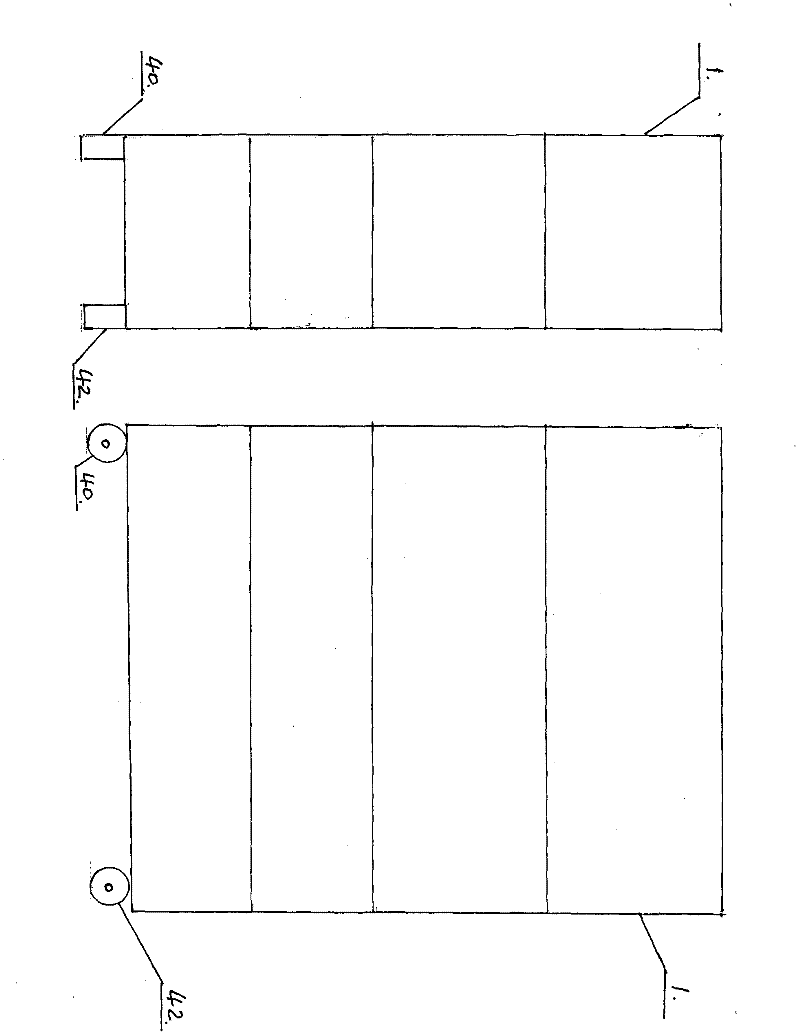

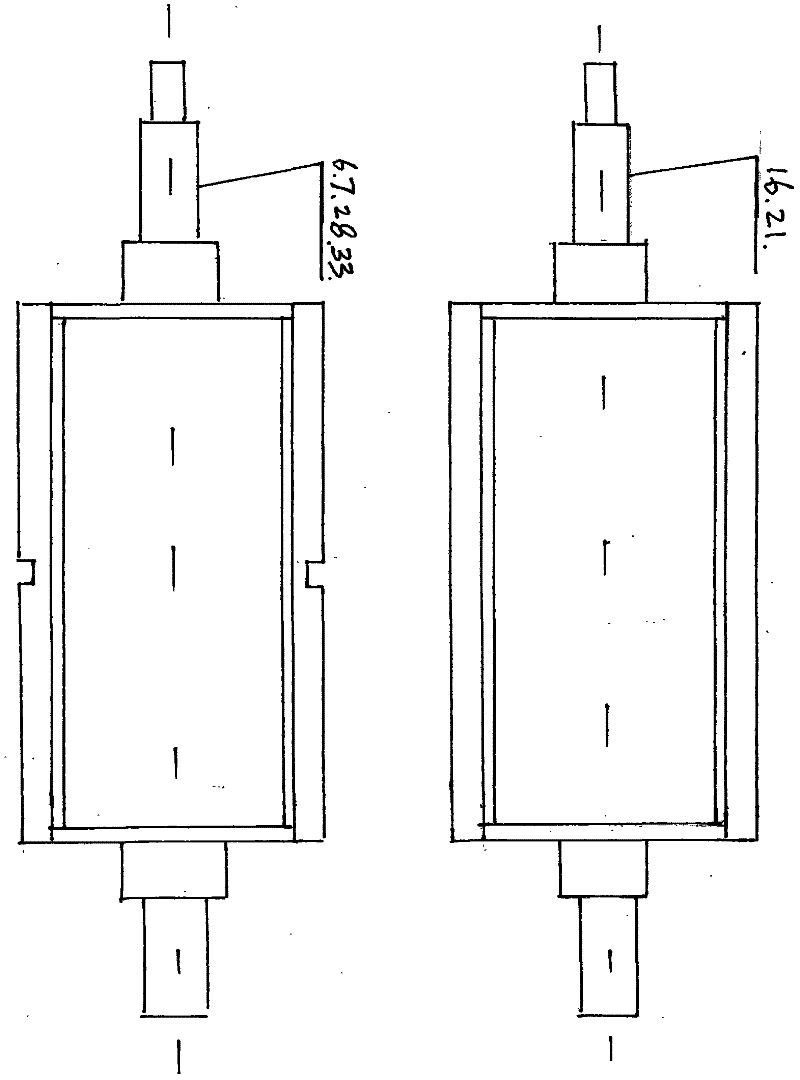

[0013] A novel double rubber roller diode straightening machine is characterized in that: universal wheels (40)-(41), steering universal wheels (42)-(43) are installed at the bottom of the four corners of the frame (1), and Material support (2), feeding support (4), straightening support (15), discharge support (26), the sequence from top to bottom is opened certain distance and is welded on the frame (1), queuing funnel ( 3), installed on the frame (1), the conveyor belt (5), set on the rubber rollers (6)-(7), bearings (8)-(9), and bearings (10)-(11) respectively On the cots (6)-(7), be fixed on the feeding support (4) again, belt disc (12) is contained on the cots (7), and the queuing funnel (14) is contained on the feeding support (4), Bearings (17)-(18) and bearings (22)-(23) are installed on the straightening rubber rollers (16)-(21) respectively, and then on the straightening support (15), the belt pulley (19) Be installed on the straightening rubber roller (16), the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com