Automatic L-shaped line molding machine

A molding machine, L-shaped technology, applied in the direction of wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve the problems of poor production consistency, large labor input, low production efficiency, etc., to achieve The effect of high production efficiency, reduction of human factors, and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

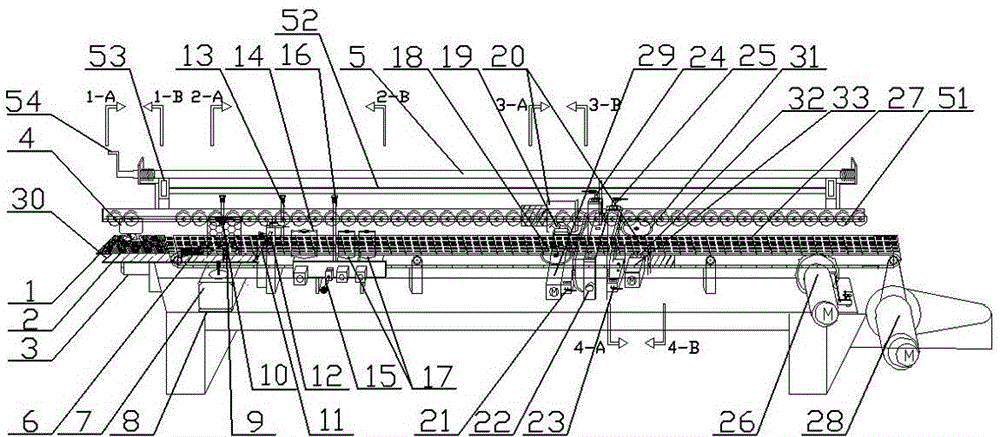

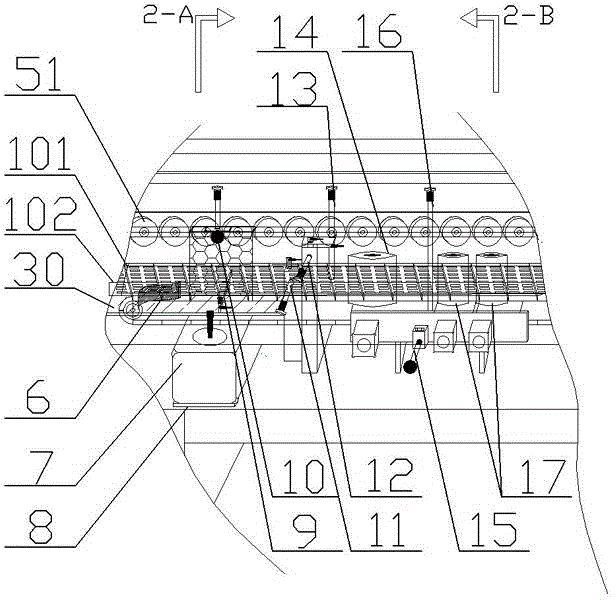

[0041] The following is based on Figures 1 to 13 Shown, the embodiment of the present invention is stated:

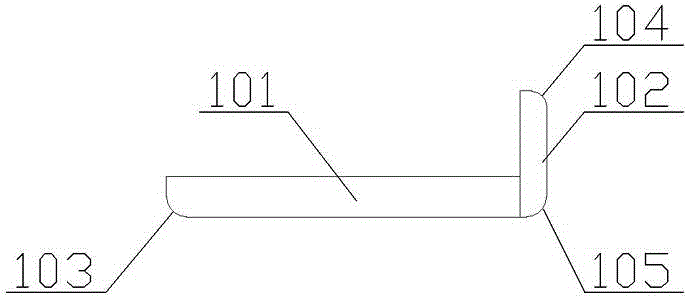

[0042] Such as Figures 1 to 13 As shown, taking the L-shaped line of a wooden door as an example, the long board 101 and the side board 102 are medium density fiberboards, the cross-sectional size of the long board 101 is 60mm*15mm, and the cross-sectional size of the side board 102 is 30mm*5mm. An automatic L-shaped line forming machine, including a speed-regulating motor 28, a conveying table 27, a side plate conveying table 30, a long plate chamfering device and a plate pressing device, the speed-regulating motor 28 drives the conveying table; the speed-regulating motor 28 A speed governor is connected, and when the speed regulating motor 28 drives the conveying table 27 to work, the conveying speed of the conveying table can be controlled by the speed governor, and the operator can adjust the speed by himself according to the glue, the material of the plate and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com