UV (ultraviolet) cured coating composition for PET (polyethylene terephthalate) base material and preparation method of composition

A composition and coating technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of high coating thickness, complicated and complicated implementation process, increased cost, etc., and achieve good tensile properties. , Good scratch resistance, reduce the effect of rainbow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0032] The preparation of the UV curable coating composition for the PET base material of present embodiment 1~3 comprises the following steps:

[0033] a. Prepare materials according to the components and parts by weight shown in Table 1; the high-refractive-index monomer is a functional monomer containing UV-curable groups with a refractive index greater than or equal to 1.55;

[0034] b. Put the solvent into the reaction kettle, add the additive and the photoinitiator while stirring, and stir until completely dissolved;

[0035] c. Put the UV-curable resin and the high-refractive-index monomer into the reactor, stir (1.5 hours) until completely dissolved, and then stop stirring;

[0036] d. Stir slowly for another 20 minutes and filter to obtain the UV curable coating composition for PET substrates.

Embodiment 4

[0038] The preparation steps of this embodiment are the same as those of Examples 1-3, except that the stirring time in step c is 0.5 hour; the slow stirring time in step e is 10 minutes.

Embodiment 5

[0040] The preparation steps of this example are the same as those of Examples 1-3, except that the stirring time in step c is 2.5 hours; the time of slow stirring in step e is 30 minutes.

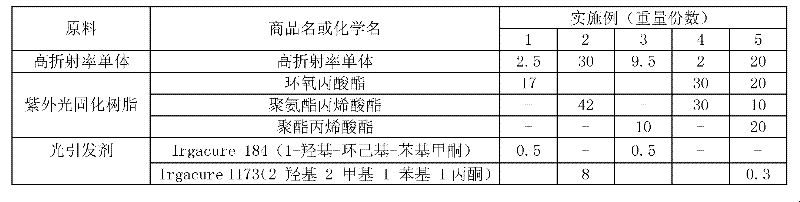

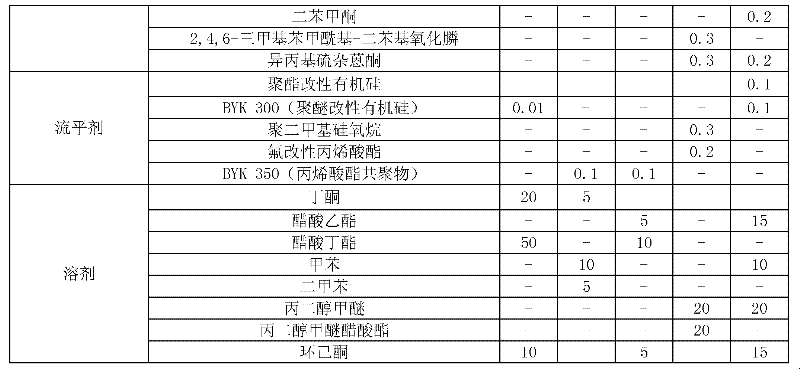

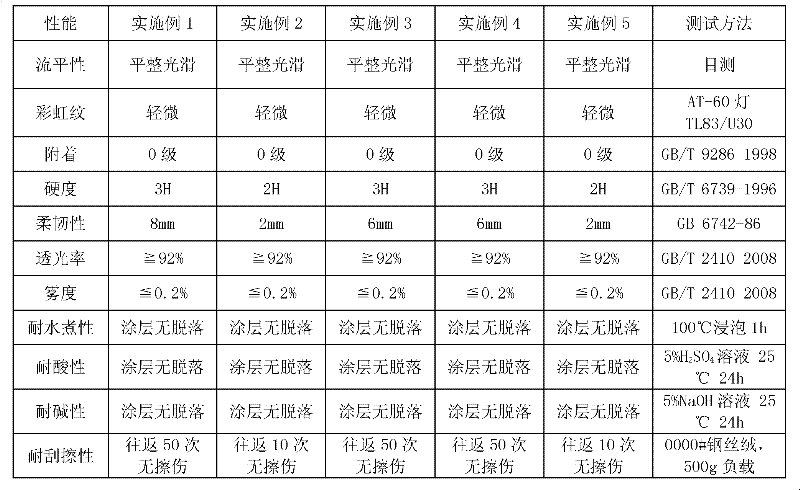

[0041] Each component and parts by weight in the embodiment 1~5 of table 1

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com