Cylindrical roller multi-circular-arc variable curvature profile engineering simulation method

A technology of cylindrical roller and simulation method, applied in the field of crown design of cylindrical roller, roller, tapered roller, inner and outer ring raceway, to overcome the boundary stress concentration effect and reduce the processing and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

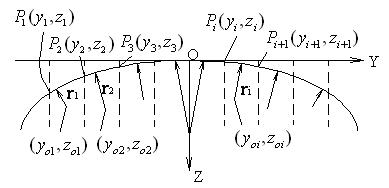

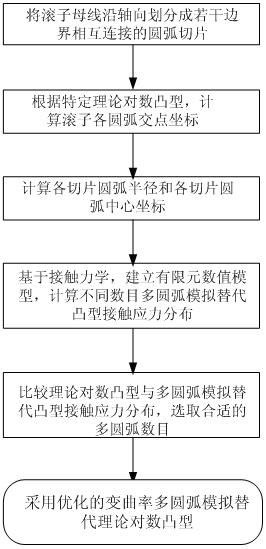

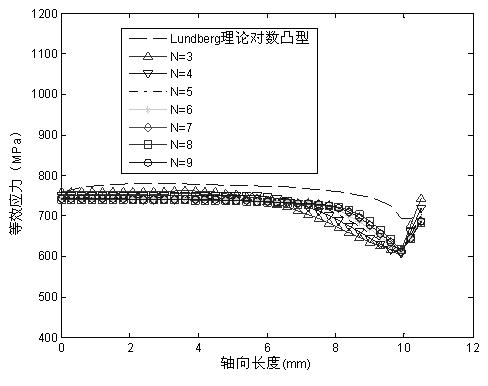

[0033] Such as figure 1 , figure 2 As shown in , an engineering simulation method of multi-arc variable curvature convex shape of cylindrical rollers, firstly, the cylindrical rollers are divided into several interconnected arc slices along the axial direction, and then according to the given special logarithm Calculate the coordinates of the intersection points of the boundary lines of each slice using the curve, and then use the equations of the adjacent arc segments and the line connecting the two arc segments to solve the arc center coordinates and arc radius values of each segment; based on the theory of contact mechanics, calculate and analyze different numbers of variables Under the arc-convex curvature, the contact stress distribution along the axis of the roller is compared with the contact stress distribution of the theoretical logarithmic convex shape, so as to optimize the number of arcs with variable curvature.

[0034] Such as Figure 5 , Figure 6 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com